Anti-explosion frequency conversion and energy saving centrifugal ventilator

A technology of centrifugal fan and air outlet pipe, which is applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc. It can solve the problems of bulky body, inconvenient use, inconvenient adjustment of the air outlet direction, etc., and achieve safety High, easily adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

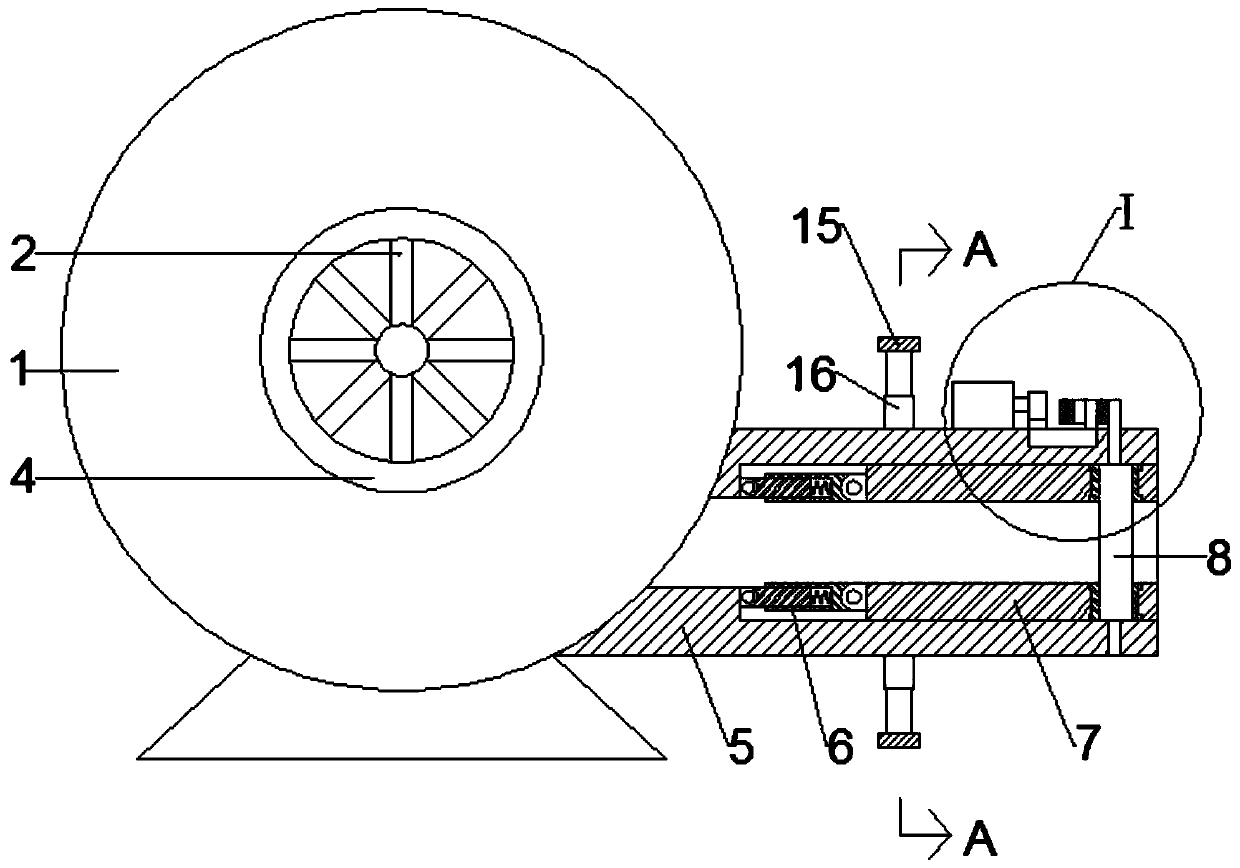

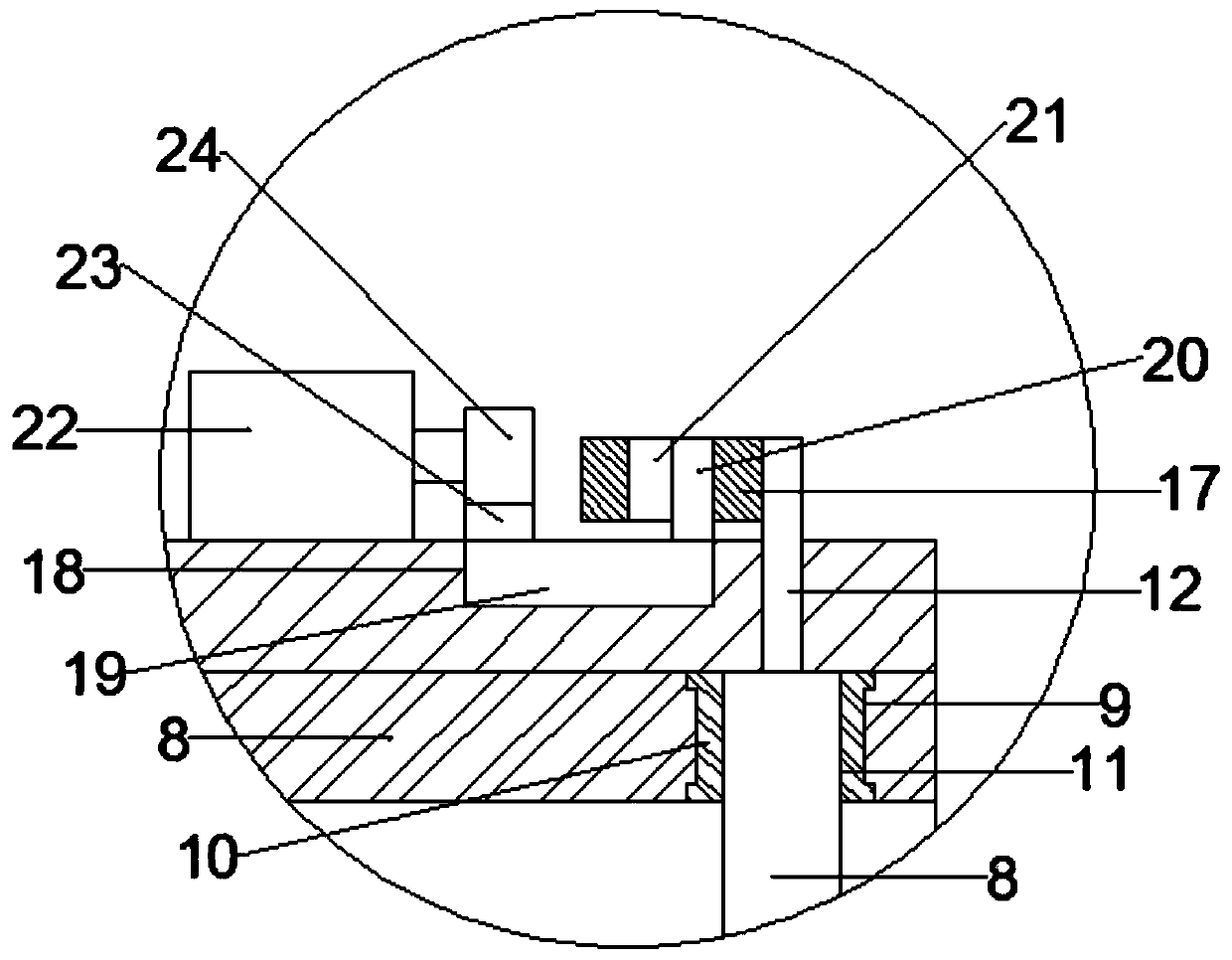

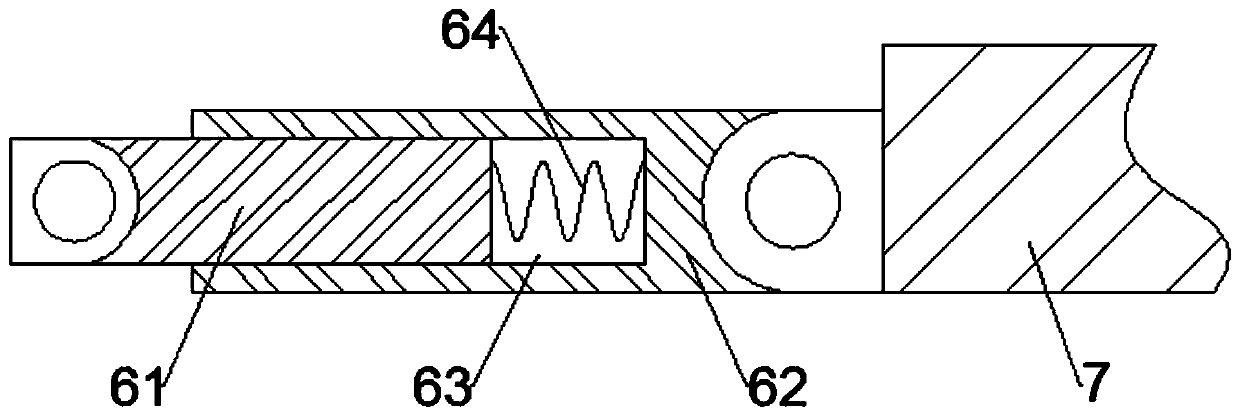

[0022] like Figure 1 to Figure 7 As shown, an explosion-proof frequency conversion energy-saving centrifugal fan includes a cylindrical shell 1, an impeller 2 is arranged inside the shell 1, and a motor for driving the impeller 2 to rotate is fixedly installed on the outside of one end of the shell 1. The drive motor 3, the outer side of the other end of the housing 1 is fixedly installed with the air inlet pipe 4 communicating with the inner cavity of the housing 1, and the outer peripheral surface of the housing 1 is fixedly installed with the The inner cavity of the body 1 is connected to the air outlet pipe 5; the driving motor 3 drives the impeller 2 to rotate, and when the impeller 2 rotates, the air is sucked into the housing 1 from the air inlet pipe 4 and then discharged from the air outlet pipe 5. The air outlet pipe 5 extends laterally, and two deflectors 6 are arranged up and down oppositely in the air outlet pipe 5, and one ends of the two deflectors 6 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com