Semiconductor plasma machine

A plasma machine and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, circuits, discharge tubes, etc., can solve problems such as poor sealing effect, and achieve the effects of improving uniformity, solving poor sealing effect, and improving sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

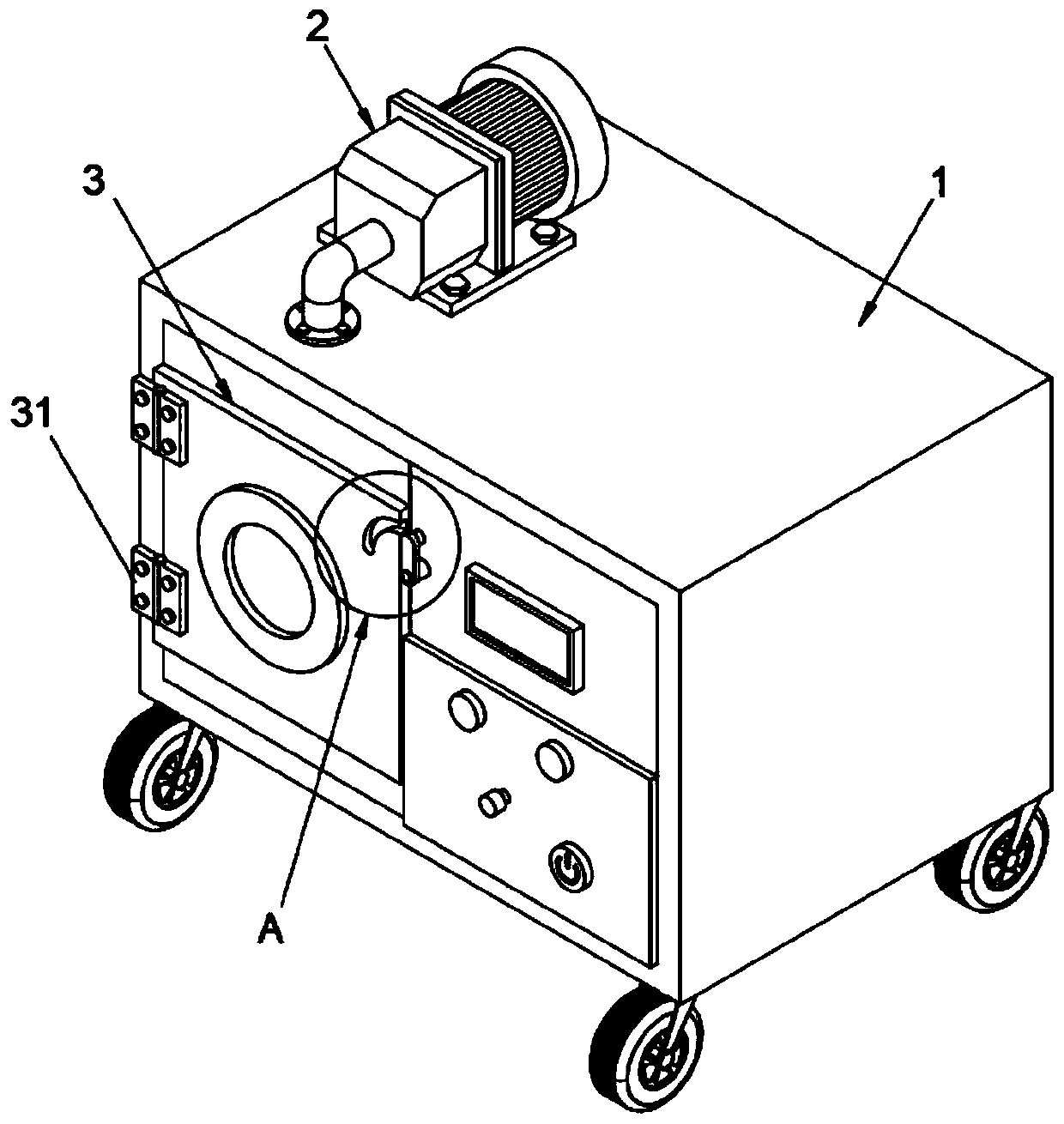

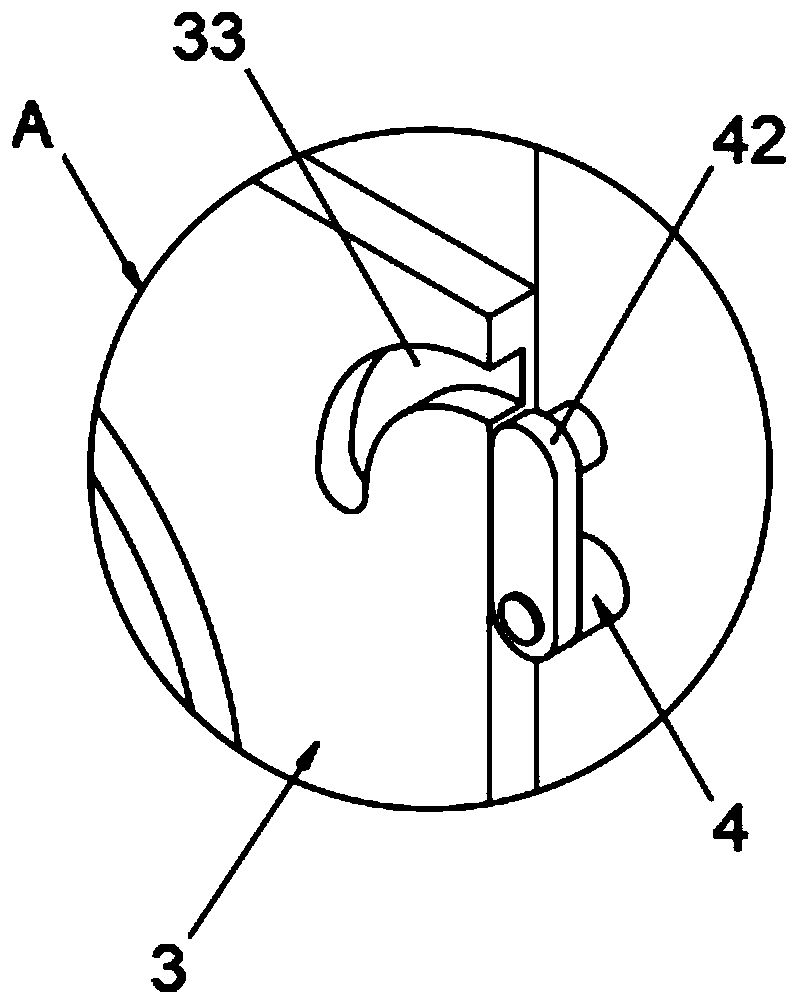

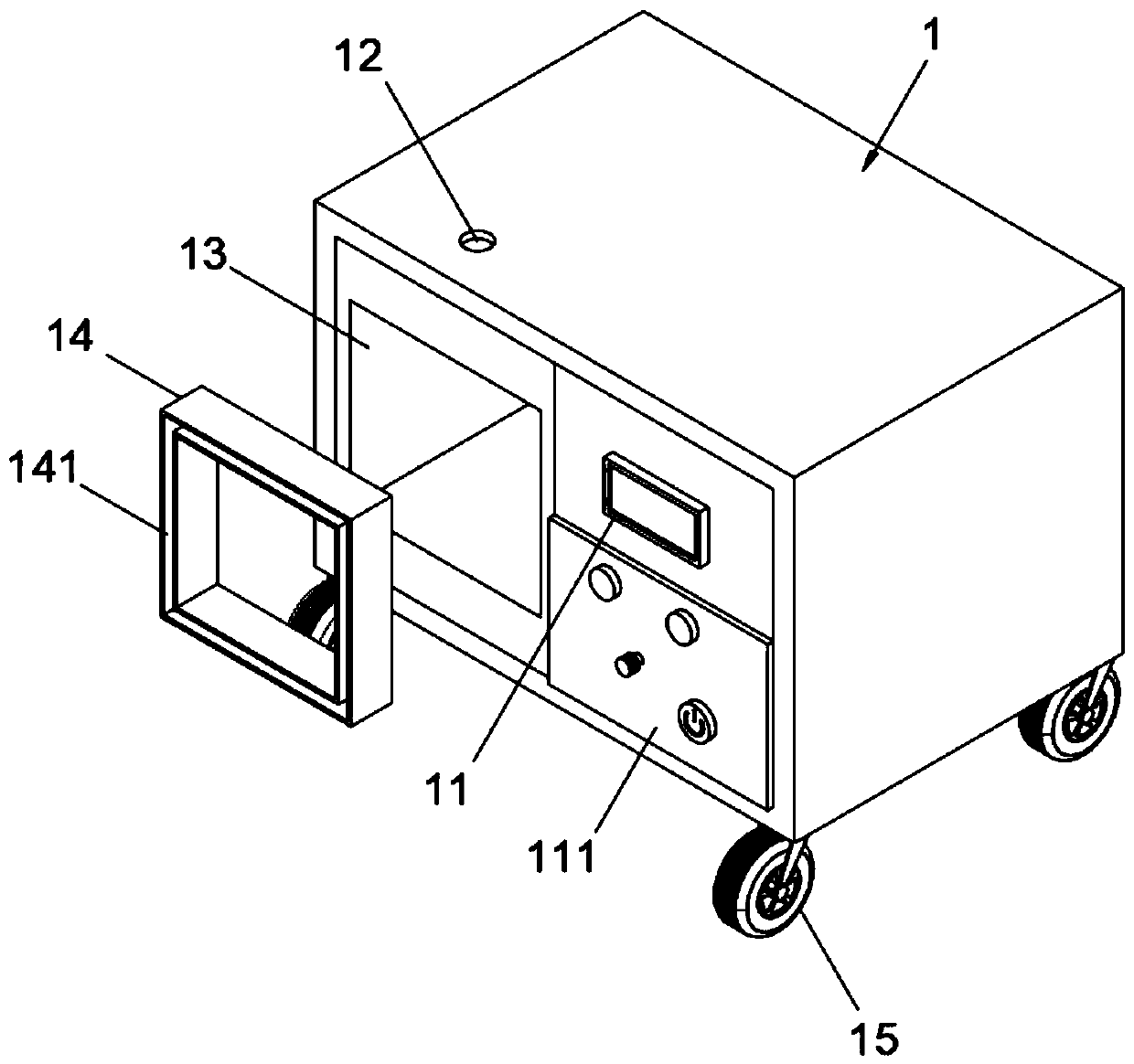

[0028] A semiconductor plasma machine, such as Figure 1-6 As shown, the plasma machine body 1 is included, the front surface of the plasma machine body 1 is provided with a display screen 11, the bottom of the display screen 11 is provided with a control panel 111, and the upper surface of the plasma machine body 1 is provided with a through hole 12. The front surface of the plasma machine body 1 is located on one side of the display screen 11 and is provided with an etching chamber 13. The through hole 12 communicates with the etching chamber 13. The upper surface of the plasma machine body 1 is provided with a vacuum pump 2, and both sides of the vacuum pump 2 are provided with a second vacuum pump. One bolt 21, the vacuum pump 2 is fixedly connected with the upper surface of the plasma machine body 1 through the first bolt 21, the output end of the vacuum pump 2 is provided with a suction pipe 22, and one end of the suction pipe 22 extends into the etching chamber 13 throug...

Embodiment 2

[0040] As the second preferred embodiment of the present invention, the four corners of the lower surface of the plasma machine body 1 are equipped with rollers 15 , which facilitates the movement of the plasma machine body 1 by the rollers 15 .

Embodiment 3

[0042] As a third preferred embodiment of the present invention, a gasket 232 is provided at the joint between the flange 23 and the through hole 12 , so that the gasket 232 can be used to improve the sealing effect between the exhaust pipe 22 and the through hole 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com