Three-channel efficient continuous flow photochemical mixing device and mixing method thereof

A mixing device and photochemical technology, applied in the field of flow photochemistry, can solve the problems of difficult mixing effect, time-consuming, local overheating danger, etc., and achieve the effects of reducing potential safety hazards, improving multi-step synthesis, providing mixing effect and heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

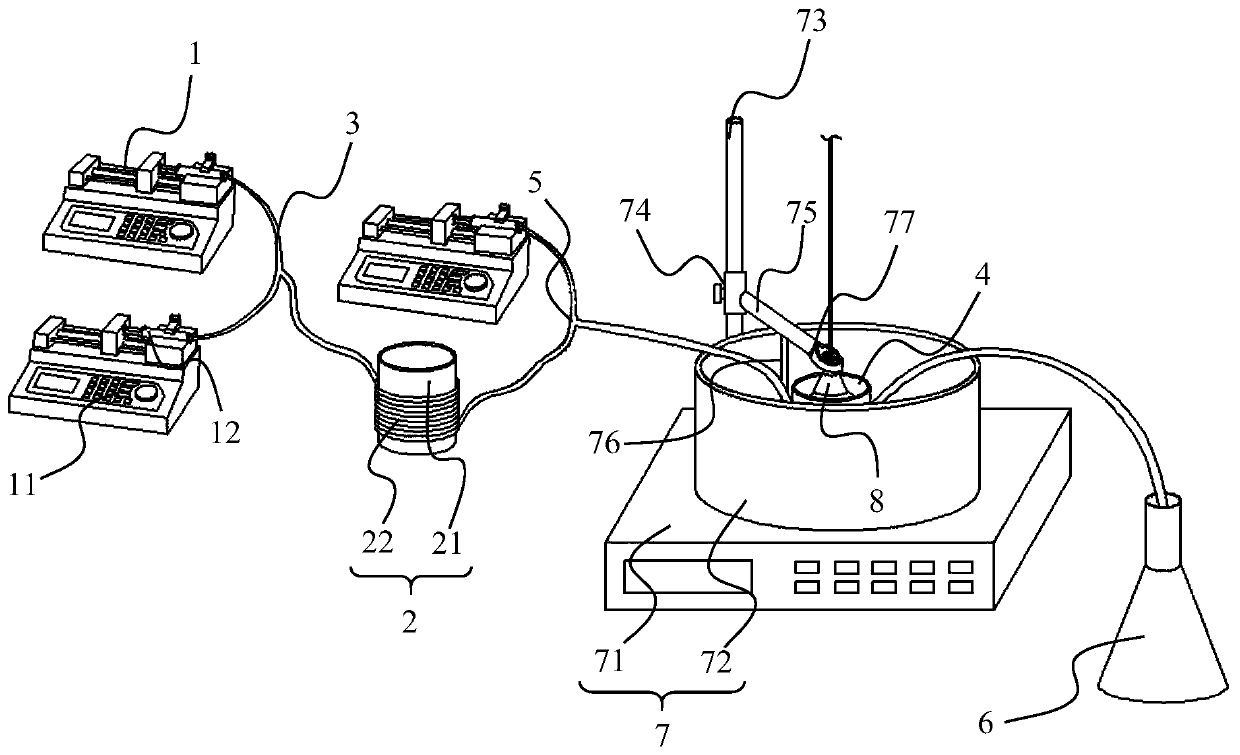

[0057] See attached figure 1 And attached figure 2 , the embodiment of the present invention discloses a three-channel high-efficiency continuous flow photochemical mixing device, comprising: an injection assembly 1, a first reaction assembly 2, a first Y-shaped pipeline 3, a second reaction assembly 4, a second Y-shaped pipeline 5 and collection container 6;

[0058]The injection assembly 1 includes three injection pumps 11, and syringes 12 respectively installed on the injection pumps 11;

[0059] The first reaction assembly 2 includes a first carrier 21, and a first reaction pipeline 22 spirally wound and fixed on the outer wall of the first carrier 21;

[0060] Two openings in the first Y-shaped pipeline 3 communicate with the injection ports of the two syringes 12 respectively, and the other opening communicates with the inlet of the first reaction pipeline 22;

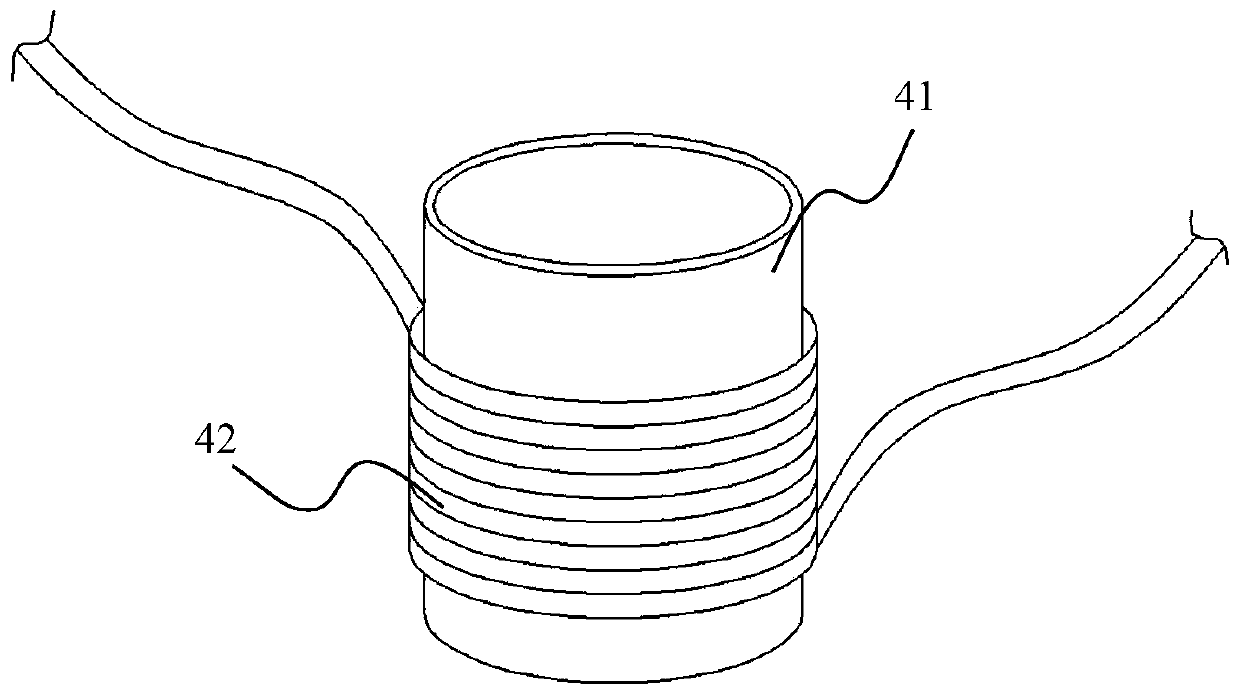

[0061] The second reaction assembly 4 includes a second carrier 41, and a second reaction pipeline 42 spir...

Embodiment 2

[0071] The embodiment of the present invention discloses a mixing method of a three-channel high-efficiency continuous flow photochemical mixing device, comprising the following steps:

[0072] S1. According to different mixing requirements, set different driving flow rates for the syringe pump 11;

[0073] S2. First start the two syringe pumps 11 connected to the first Y-shaped pipeline 3, so that two different materials are pushed out from the two syringes 12, flow through the first Y-shaped pipeline 3 and then pass through the first reaction pipeline 22 The inlet enters the spiral flow mixing in the first reaction pipeline 22, and enters the second Y-shaped pipeline 5 from the outlet of the first reaction pipeline 22;

[0074] S3. Start the syringe pump 11 connected to the second Y-shaped pipeline 5, so that the third material is pushed out from the syringe 12, flows through the second Y-shaped pipeline 5 and the mixed material in S2 converges again, and passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com