Numerically controlled vertical lathe

A numerical control vertical and lathe technology, which is applied in the field of numerical control lathes, can solve the problems of increased processing cost, complicated cleaning and disassembly, and high maintenance cost, and achieves the effects of reducing processing cost, facilitating separation from suction cups, and high clamping firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

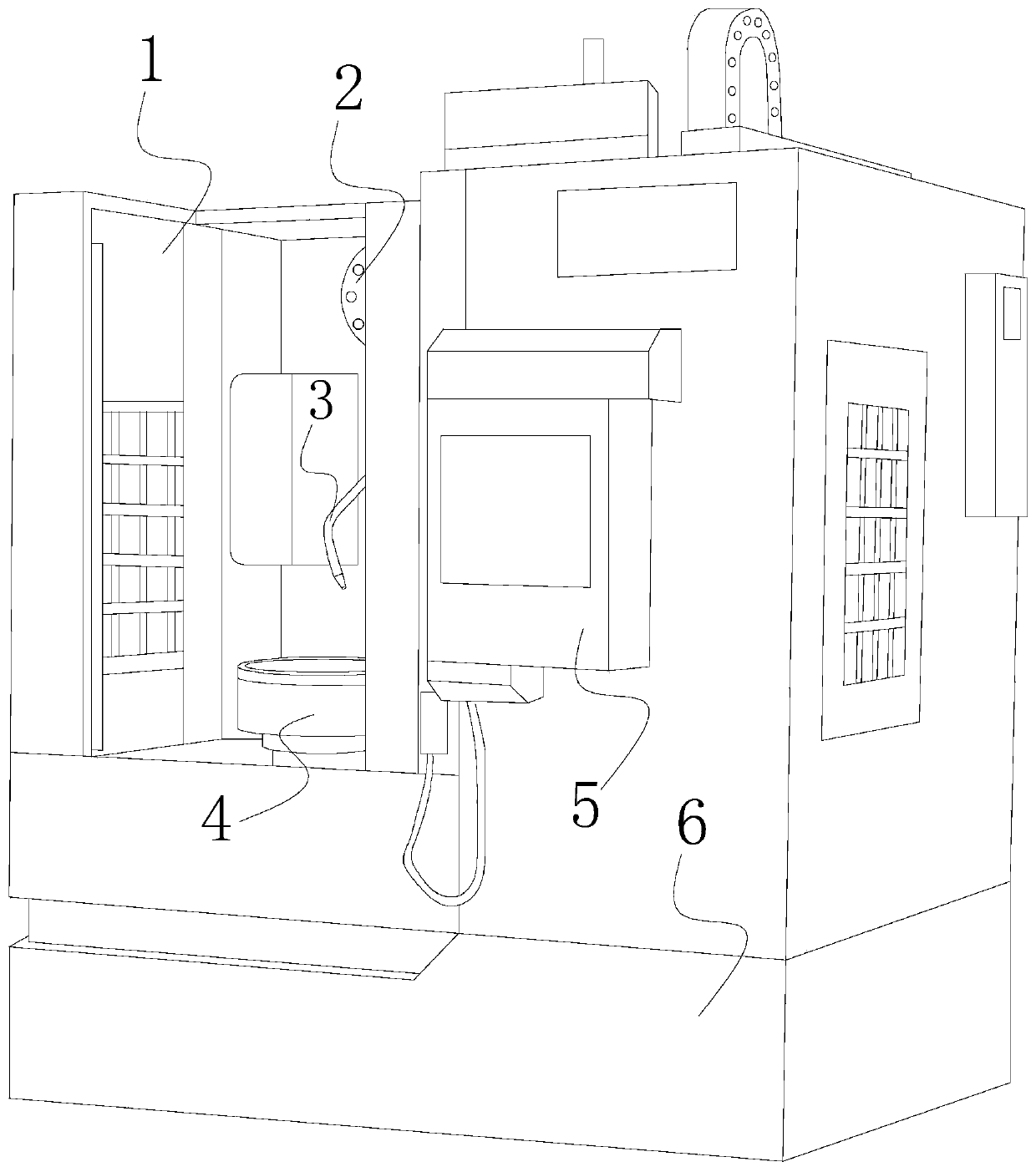

[0038] see figure 1 , the present invention provides a technical scheme of a numerically controlled vertical lathe: its structure includes a vertical bed body 1, a cutter head device 2, a cooling liquid cooling device 3, a chuck 4 for workpieces to be processed, a controller 5, and a base 6. The bottom of the vertical bed body 1 is fixed with a base 6, the outside of the vertical bed body 1 is equipped with a controller 5, and the vertical bed body 1 is provided with a cutter head device 2, a coolant cooling device 3, and a workpiece to be processed. Chuck 4;

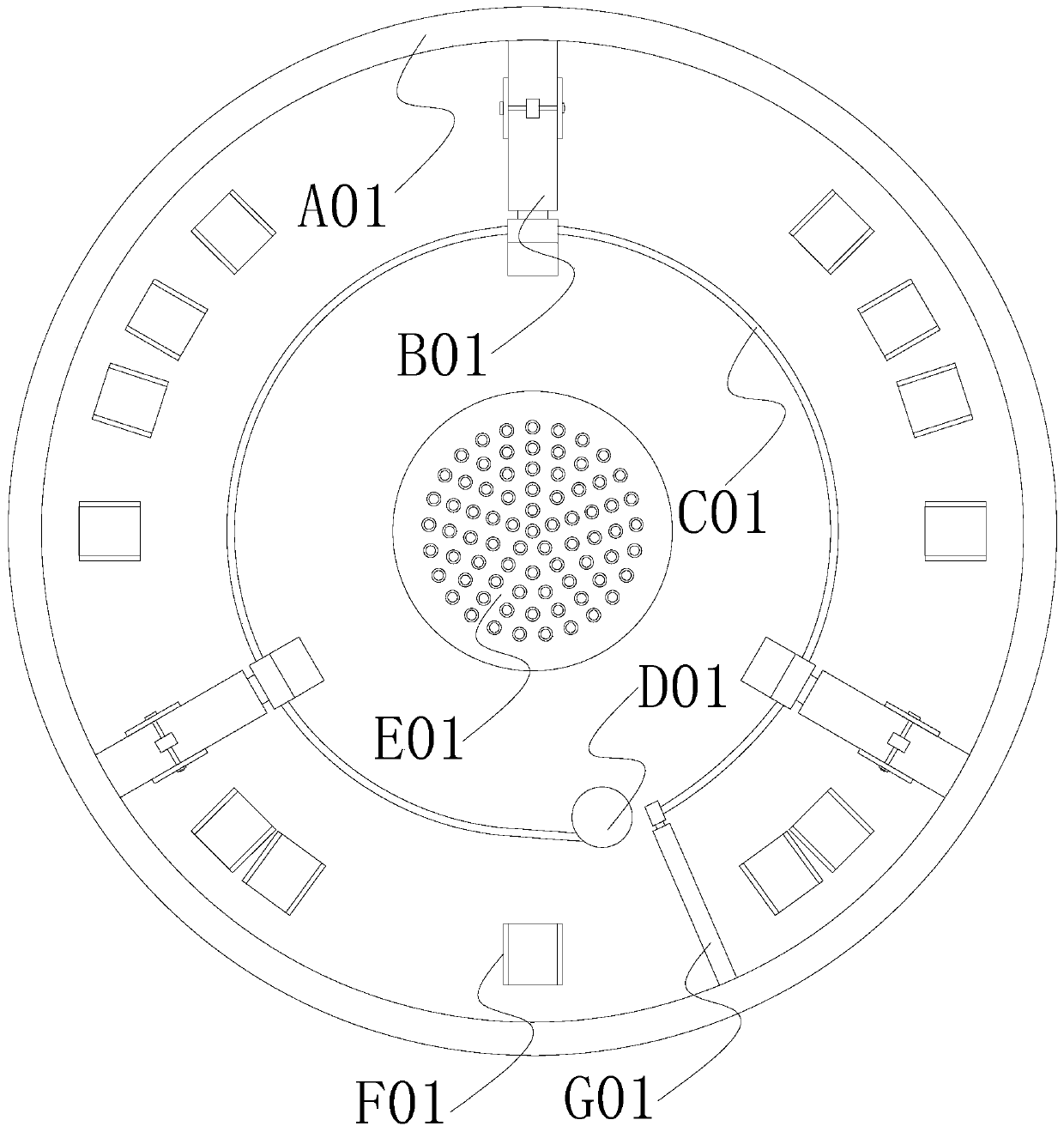

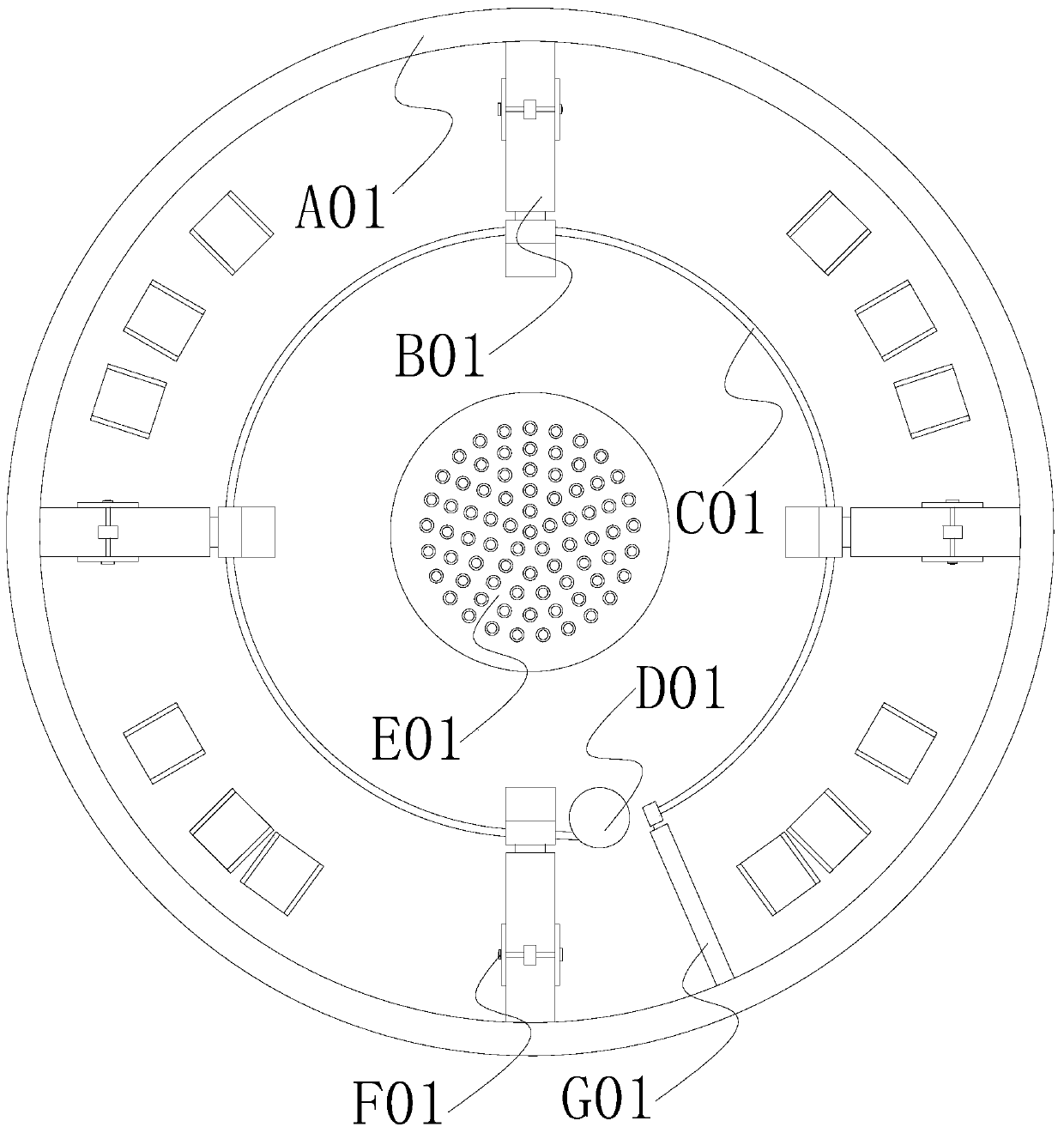

[0039] see Figure 2-7 The chuck 4 of the workpiece to be processed includes a chassis A01, a clamping group B01, a spring C01, a spring reel D01, a suction cup mechanism E01, a mounting seat F01, and a telescopic rod G01. The central position of the chassis A01 is provided with The suction cup mechanism E01, the chassis A01 is mechanically connected to the clamping group B01 through the mounting seat F01, the clampi...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical scheme of a numerically controlled vertical lathe: its structure includes a vertical bed body 1, a cutter head device 2, a cooling liquid cooling device 3, a chuck 4 for workpieces to be processed, a controller 5, and a base 6. The bottom of the vertical bed body 1 is fixed with a base 6, the outside of the vertical bed body 1 is equipped with a controller 5, and the vertical bed body 1 is provided with a cutter head device 2, a coolant cooling device 3, and a workpiece to be processed. Chuck 4;

[0044] see Figure 2-7 The chuck 4 of the workpiece to be processed includes a chassis A01, a clamping group B01, a spring C01, a spring reel D01, a suction cup mechanism E01, a mounting seat F01, and a telescopic rod G01. The central position of the chassis A01 is provided with The suction cup mechanism E01, the chassis A01 is mechanically connected to the clamping group B01 through the mounting seat F01, the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com