Optical module part machining numerical control milling machine

A technology of CNC milling machine and parts, applied in the field of mechanical processing, can solve the problems of milling waste disposal and low processing efficiency of CNC milling machine, and achieve the effects of improving efficiency, saving time and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

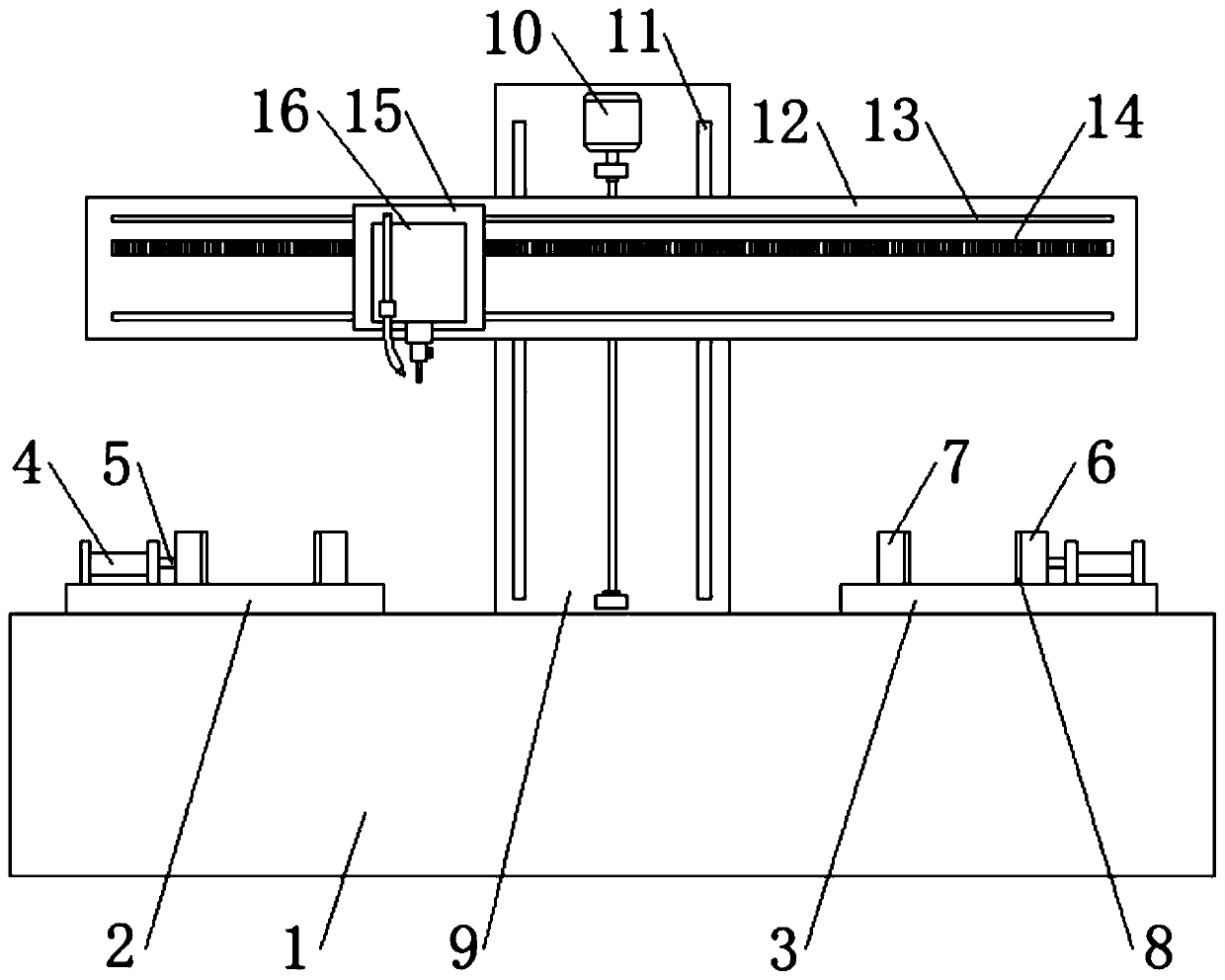

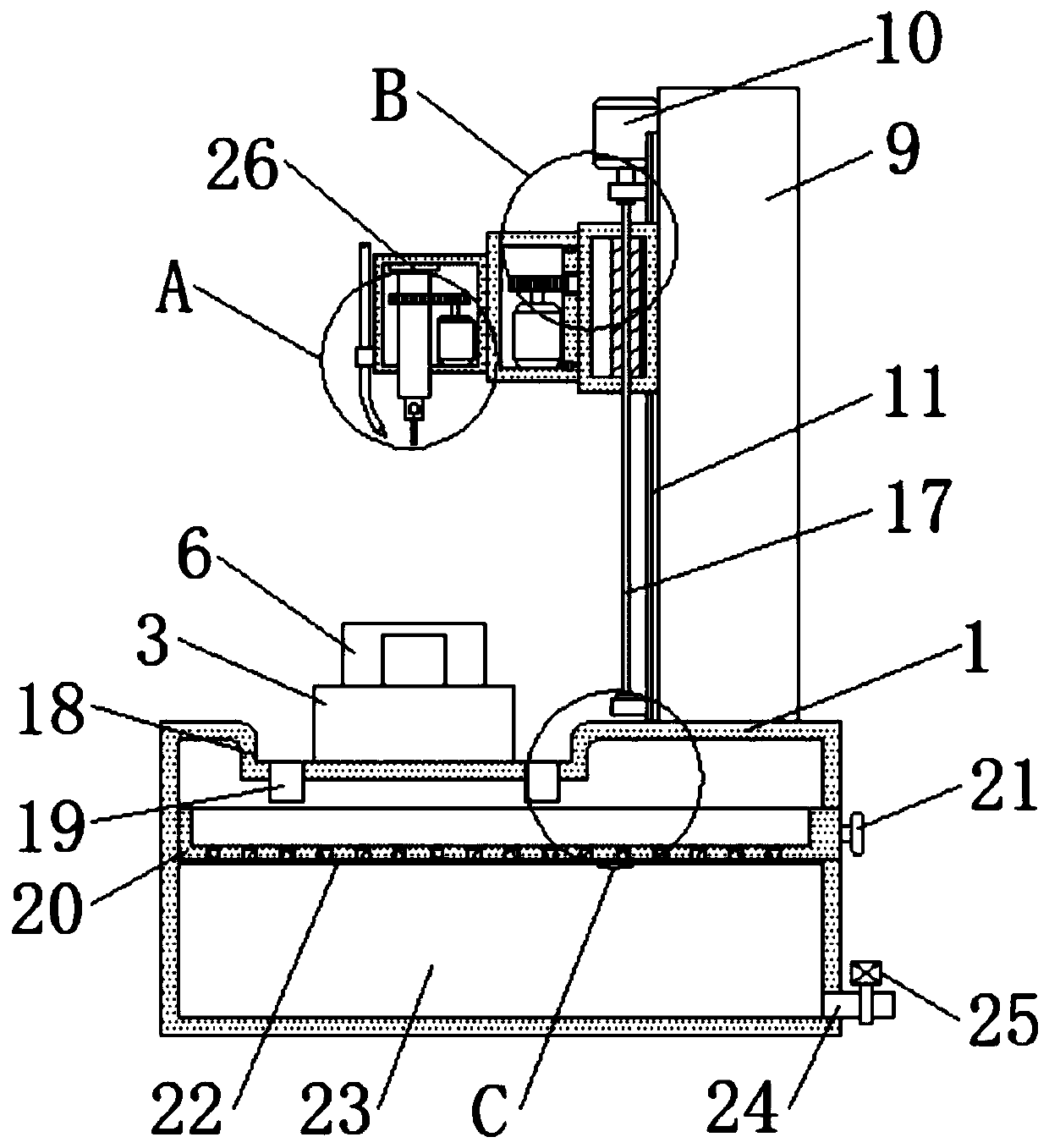

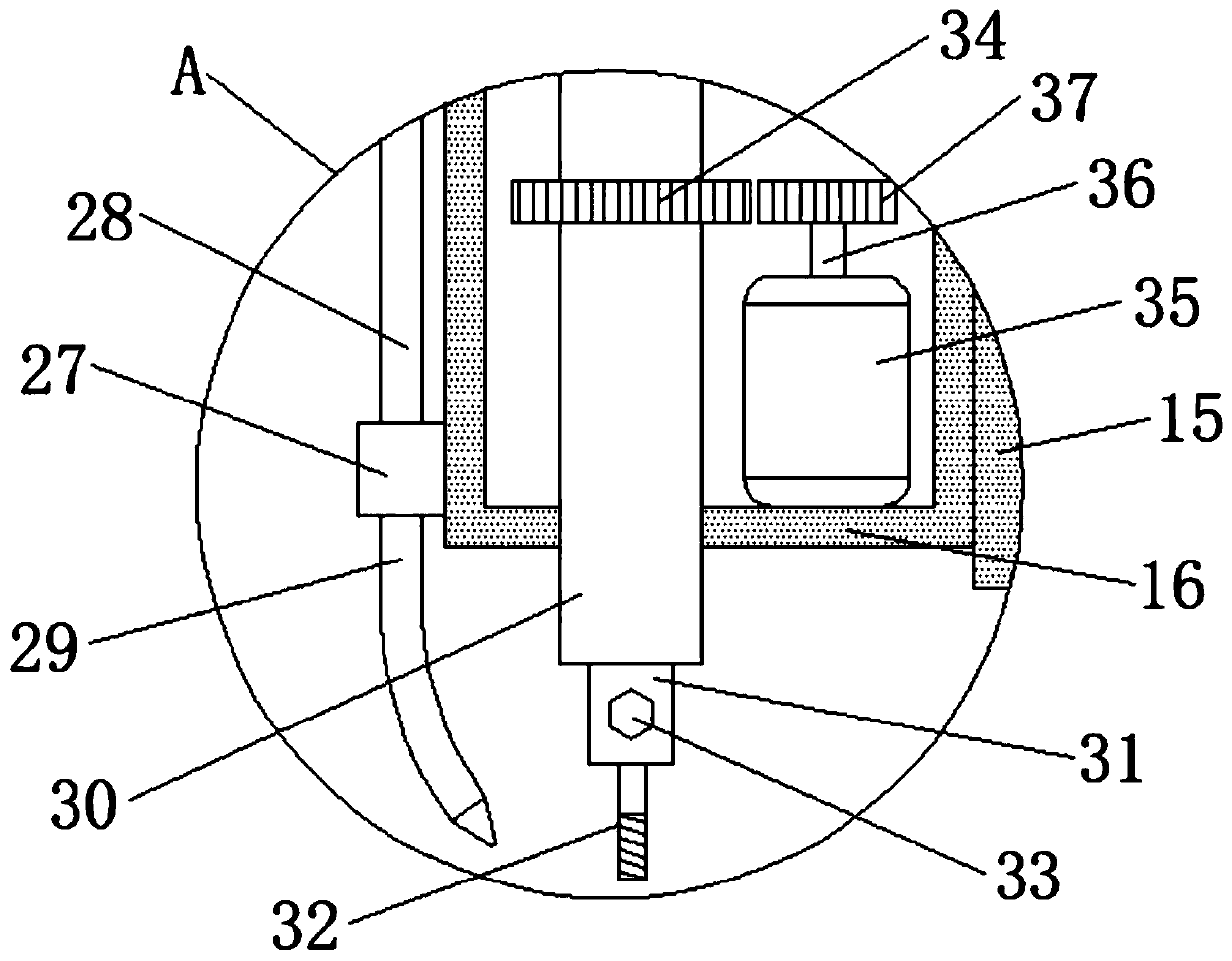

[0029] Such as Figure 1-5 As shown, the embodiment of the present invention provides a CNC milling machine for processing optical module parts, including a box body 1, a water collection tank 18 is arranged at the front end of the top of the box body 1, and a first workbench 2 is fixedly connected to one side of the water collection tank 18 and collects The other side in the water tank 18 is fixedly connected with a second workbench 3, and the workpieces to be processed are respectively clamped on the first workbench 2 and the second workbench 3, so that they can be placed on the first workbench 2 and the second workbench 3. The milling process is carried out alternately, which saves the time of clamping the workpiece during the processing and greatly improves the processing efficiency. The support column 9 is fixedly connected to the middle position of the top rear end of the box body 1, and two first Ts are fixedly connected to both sides of the front end of the support colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com