Laminating mechanism for chain saw cutter grains and device applying laminating mechanism

A technology of knives and chainsaws, applied in the field of chain saw production equipment, can solve the problems of high labor intensity of workers, inability to achieve orderly stacking of knives, time-consuming and laborious, etc. Ingenious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

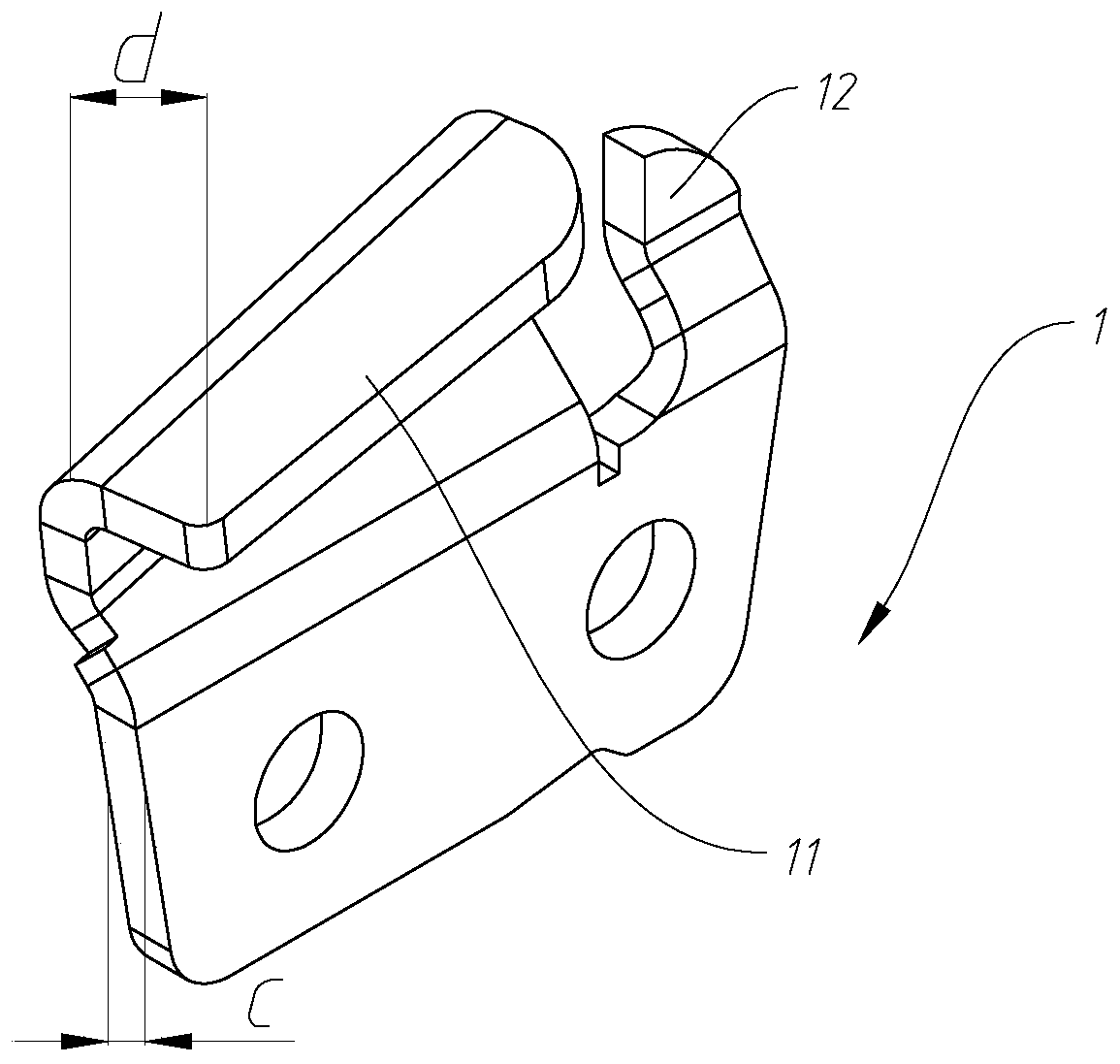

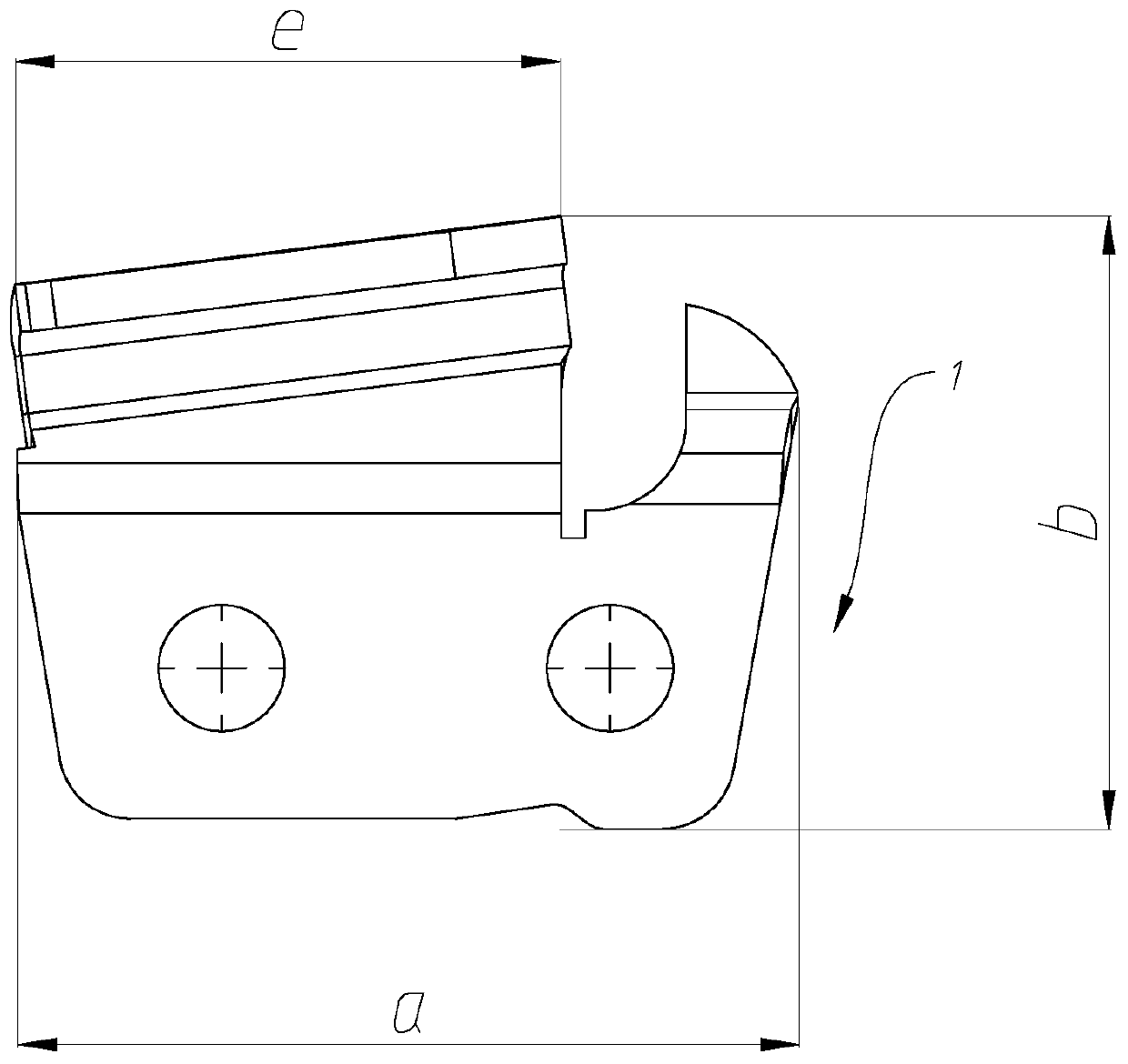

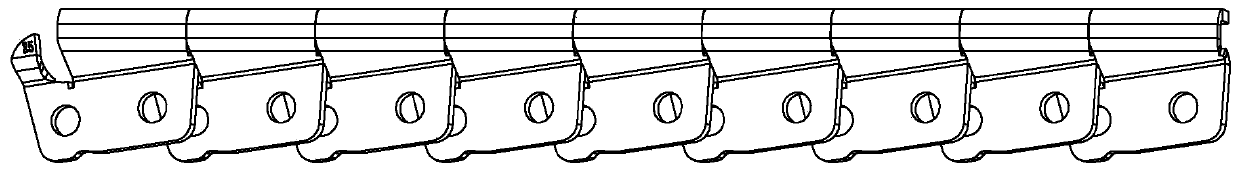

[0140] The vibrating plate 4 is an auxiliary feeding device capable of vibrating the disordered knife grains 1 into the knife grain 1 with the folded edge 11 facing downwards, with the folded edge 11 in front and the arc edge 12 behind; and then the vibrating plate 4 can transmit The kinetic energy of the knife grains 1 enables the knife grains 1 in a uniform posture according to the stacking requirements to automatically move from the cavity of the feeding trough 2 to the cavity of the stacking groove 3. This arrangement of the knife grains 1 can further facilitate The lamination of knife grain 1.

[0141] Because, being positioned at discharge port 21, the moving speed of the falling back knife grain 1 is faster than the front knife grain 1 that has moved to the feed port 31, and the position of the rear knife grain 1 is higher than the position of the previous knife grain 1, which When it is inclined downward, its folded edge 11 can just be in conflict with the arc edge 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com