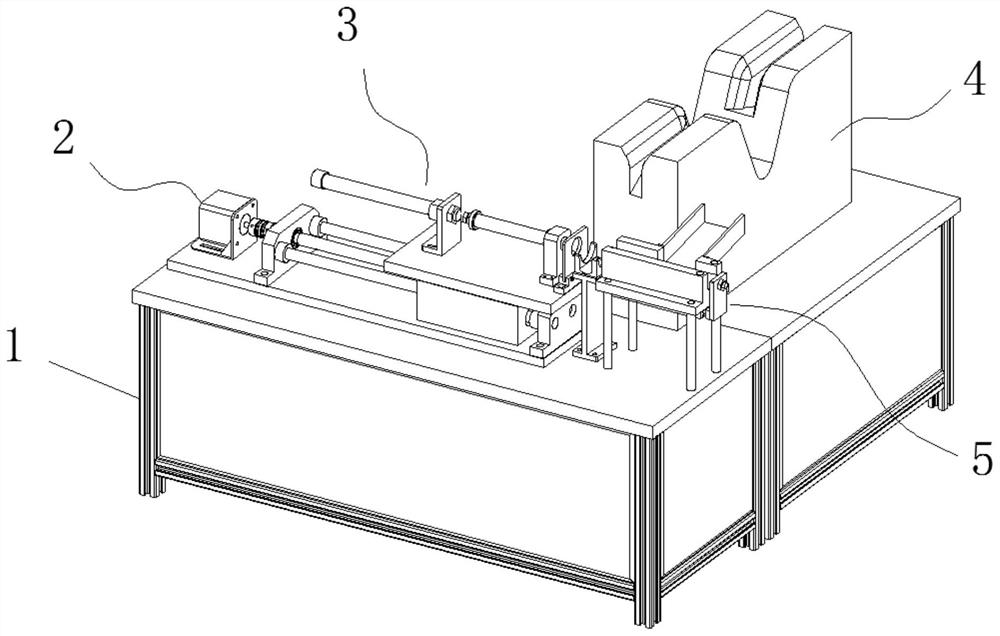

A fully automatic pedal assembly machine for automobiles

A fully automatic, assembly machine technology, applied in the direction of assembly machines, metal processing equipment, metal processing, etc., can solve the problems of difficult assembly, inability to achieve high efficiency, mass production, etc., and achieve the effect of satisfying high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

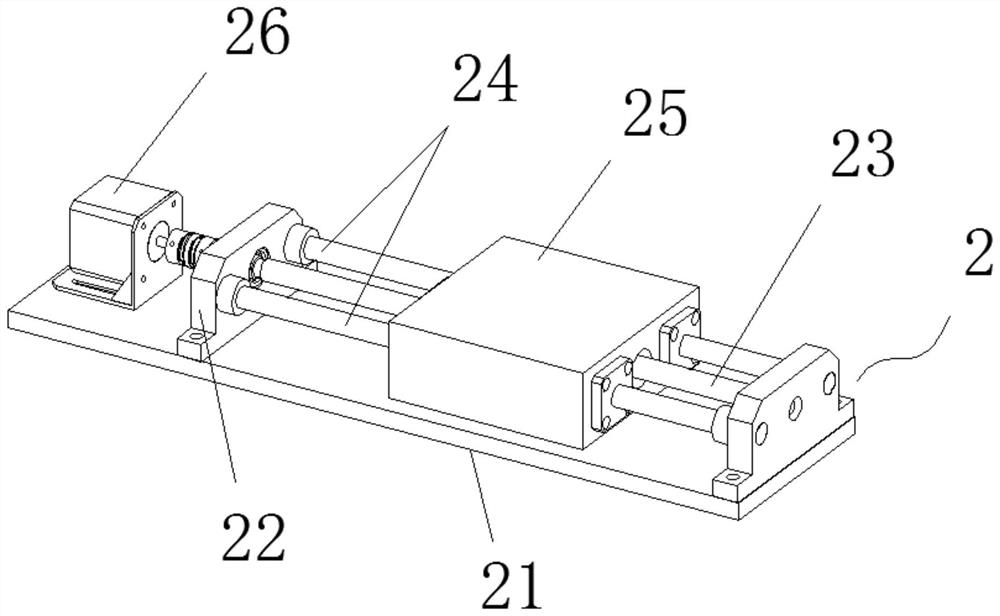

[0034] Such as figure 2 As shown, the sliding table mechanism 2 includes a sliding table bottom plate 21, a sliding table mounting seat 22 is fixed on both sides of the top surface of the sliding table bottom plate 21, and a sliding table screw rod 23 is arranged between the sliding table mounting seats 22 on both sides and symmetrically arranged. The guide slide bar 24 on both sides of the slide table screw rod 23, the two ends of the slide table screw rod 23 and the slide table mounting seat 22 are installed through bearing rotation, the two ends of the guide slide bar 24 are fixedly installed with the slide table mounting seat 22, and the two sides slide A mobile platform 25 is arranged between the platform mounting bases 22, and the sliding platform screw rod 23 and the guide slide bar 24 are screwed and slidably connected with the mobile platform 25 respectively. Inner nut sleeve, guide slide bar 24 and movable table 25 side joints are embedded with linear bearings, one ...

Embodiment 2

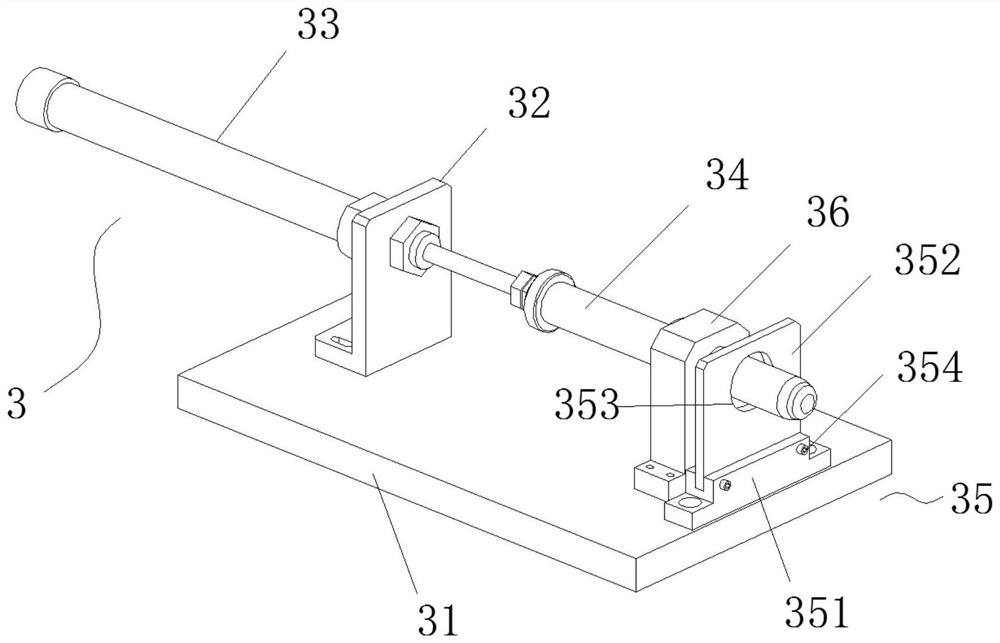

[0036] Such as image 3 As shown, the guide rod baffle plate mechanism 3 includes an installation base plate 31, the top side of the installation base plate 31 is equipped with a guide rod cylinder 33 through a guide rod cylinder seat 32, and the telescopic end of the guide rod cylinder 33 is equipped with a guide rod 34, and the guide rod 34 It is a cylinder, and the front end of the guide rod 34 is a round head structure, which is convenient to penetrate into the inner cavity of the inner sleeve of the pedal. A linear bearing seat 36 is installed between and close to the side of the baffle plate assembly 35. The front end of the guide rod 34 runs through the linear bearing seat 36 and the baffle plate assembly 35 in turn, and is slidably connected with the linear bearing seat 36. The setting of the linear bearing seat 36 ensures The guide rod 34 telescopically moves along its axis;

[0037]The baffle plate assembly 35 comprises a baffle plate inserting block 351, and the to...

Embodiment 3

[0040] Such as Figure 4 As shown, the support part and the positioning part in the support positioning mechanism 4 are distributed at intervals before and after, the support part includes a support block 41, and the top of the support block 41 is provided with a pedal rod limit groove 42, and the top of the support block 41 is perpendicular to the pedal rod limit. The direction of the position groove 42 is provided with the jaw relief groove 43, and the positioning part comprises the I-shaped support seat 44, and the top of the I-shaped support seat 44 is equipped with a positioning block 45, and the top of the positioning block 45 is provided with a positioning arc groove 46, and the positioning The top of the block 45 is perpendicular to the positioning arc groove 46 and is provided with a pedal rod give way groove 47. After the pedal is placed, its rod is fixed by cooperating with the pedal rod limit groove 42. The fixed sleeve at the front end and the positioning arc groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com