Injection mold for plastic packaging product

An injection mold and plastic packaging technology, applied in the field of injection molding of plastic packaging products, can solve problems such as reducing work efficiency, and achieve the effects of improving work efficiency, speeding up flow speed, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

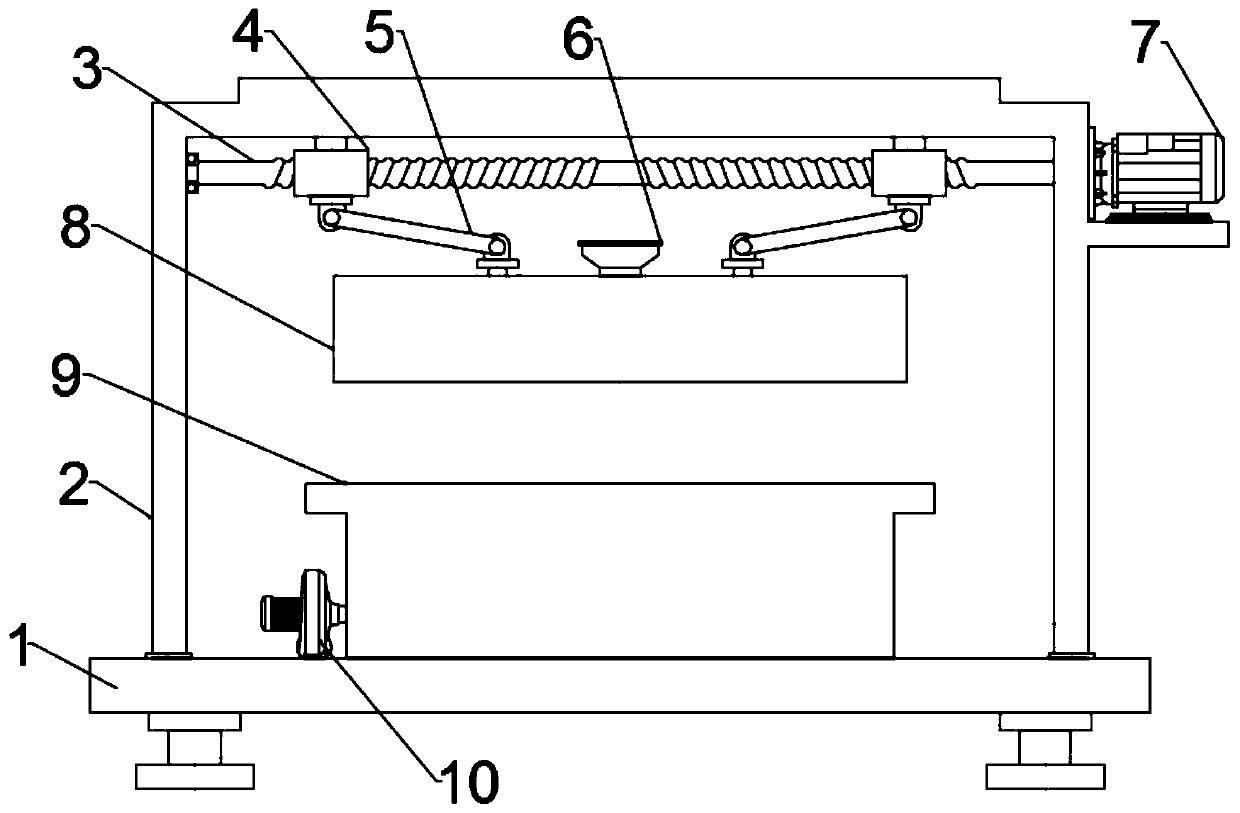

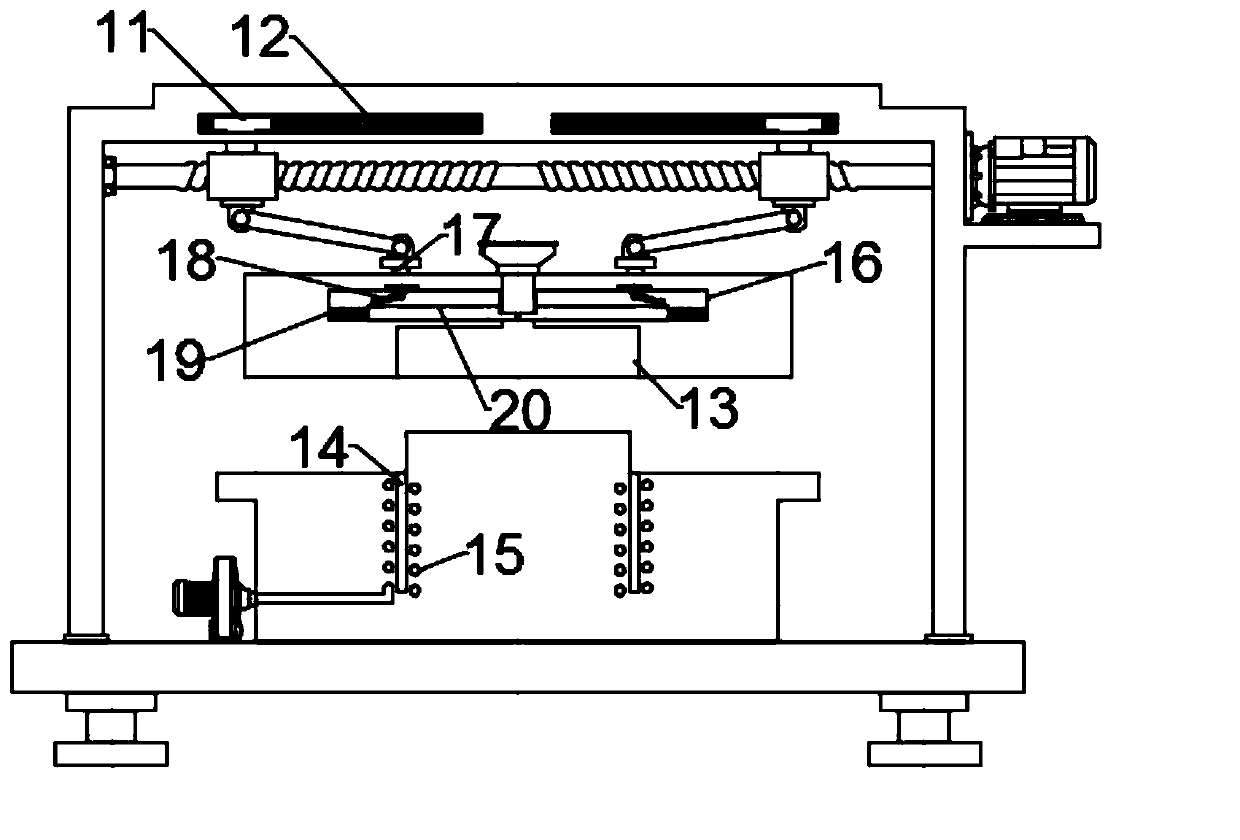

[0023] In an embodiment of the present invention, an injection mold for plastic packaging products includes a bottom plate 1, a bracket 2 fixed on the bottom plate 1, an upper mold 8 connected to a lifting mechanism, and a lower mold 9 fixed on the bottom plate 1; The upper mold 8 is located directly above the lower mold 9, and the lifting mechanism drives the relative lower mold 9 of the upper mold 8 to move up and down. The upper mold 8 is provided with an injection port 6 for injection molding liquid to pour into, and the injection port 6 communicates with the upper mold position 13 arranged in the upper mold 8, and the two sides of the flow channel that the injection port 6 communicates with the upper mold position 13 are symmetrically provided with movable chambers 16, and the inner side of the movable chamber 16 slides through the movable chamber The cutting rod 20 on the side wall of 16, the upper side of the cutting rod 20 away from the flow channel is hinged with the m...

Embodiment 2

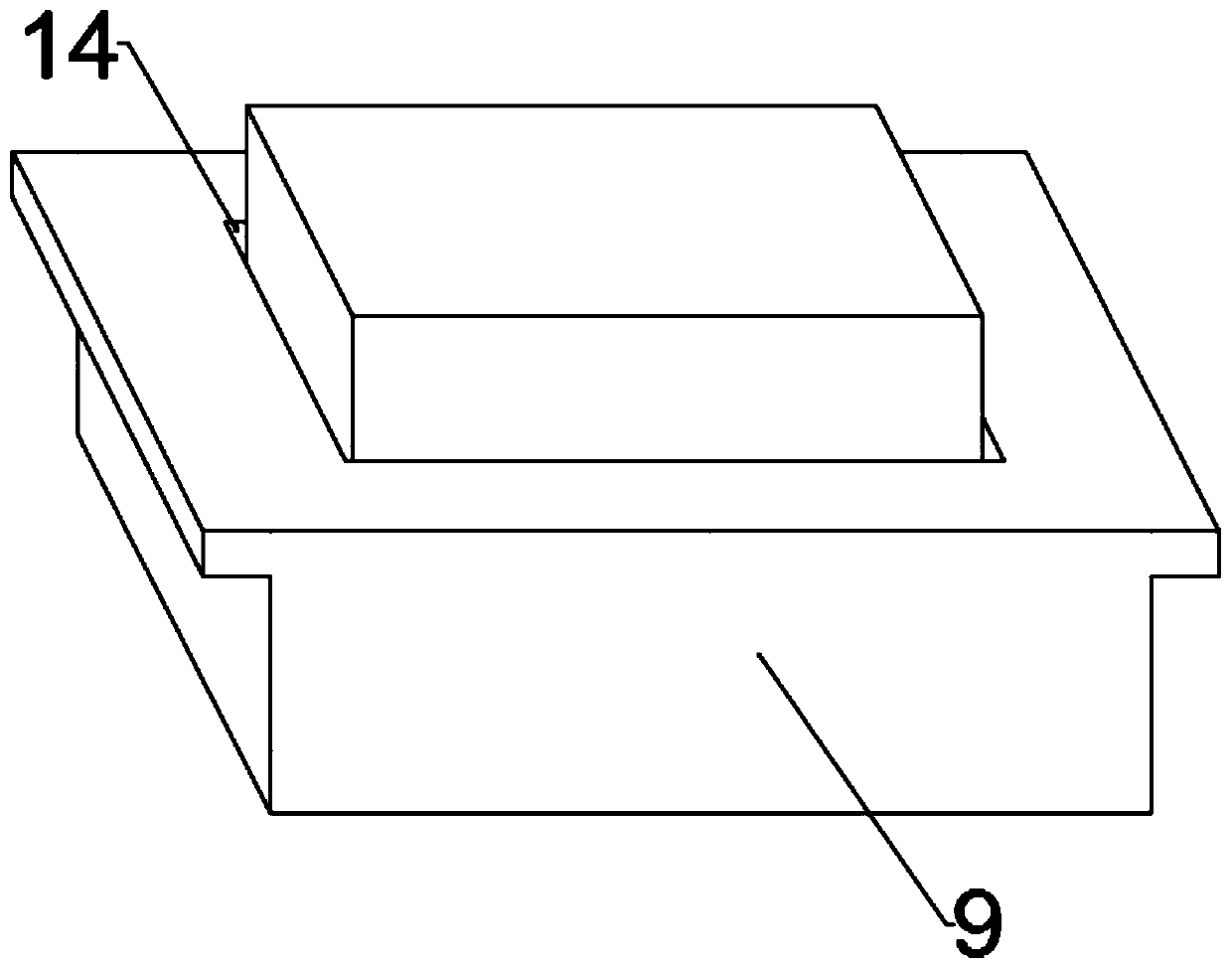

[0031] In order to speed up the cooling of injection molded products, the present invention also proposes another embodiment to improve the present application during the specific implementation process. Specifically, the side end of the lower mold 9 is provided with a fan 10, and the air outlet of the fan 10 is connected with the It communicates with the heat dissipation channel 15 in the lower mold 9, and the fan 10 can effectively accelerate the flow rate of the gas in the heat dissipation channel 15 when working, thereby increasing the cooling of the injection molded product.

[0032] The heat dissipation passages 15 are evenly distributed on the inner and outer ends of the lower mold position 14 to realize simultaneous heat dissipation inside and outside the injection molded product, and the heat dissipation effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com