Heat supply pipeline connecting structure and construction method thereof

A technology for connecting structures and heating pipes, which is applied in the directions of pipe supports, pipe laying and maintenance, pipes/pipe joints/fittings, etc. The effect of a small load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

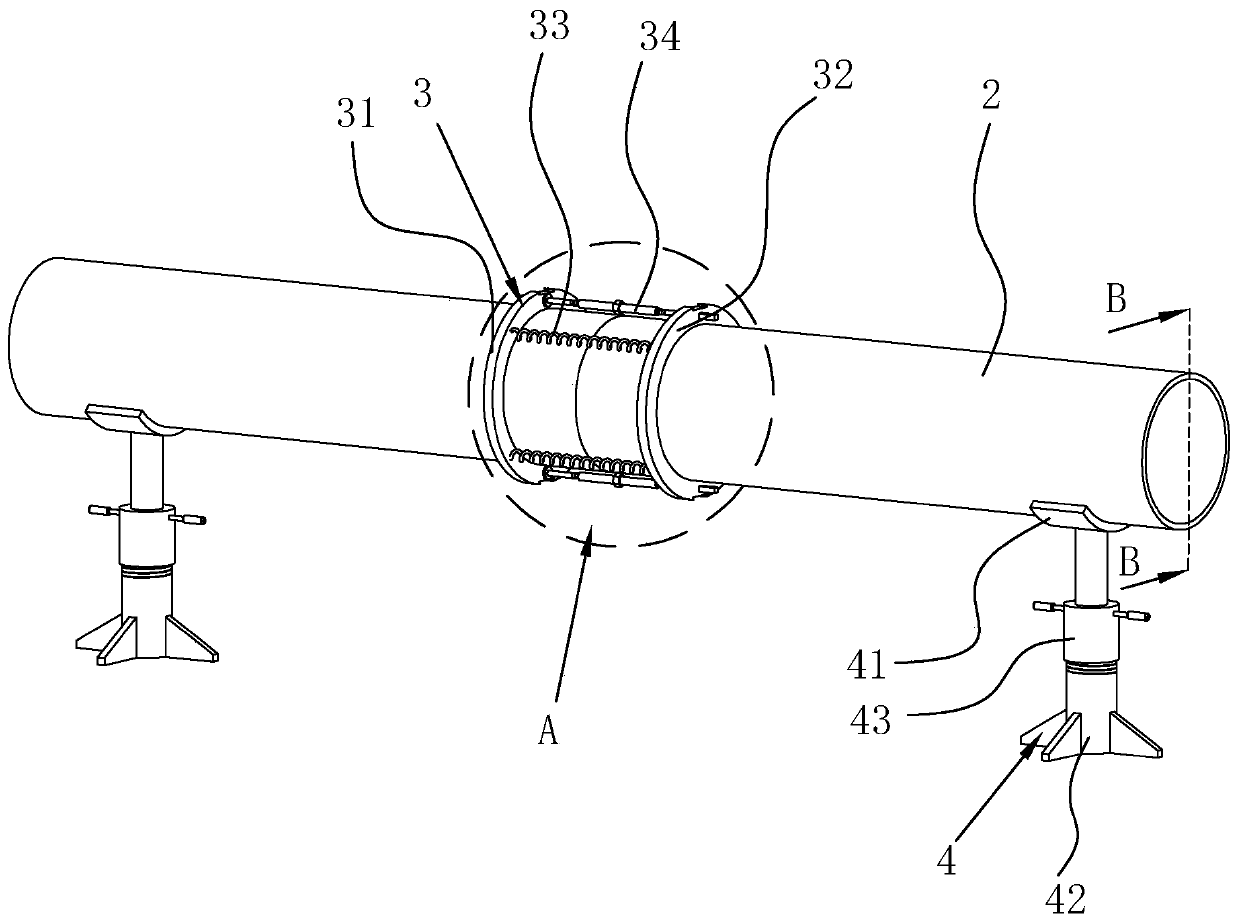

[0055] refer to figure 1 , is a connection structure for heating pipes disclosed in this embodiment of the present invention, including several pipes 2 connected end to end, a connecting piece 3 arranged between two adjacent pipes 2 and a prefabricated pipe supported under the two ends of the pipes 2. The support 4, the pipeline 2, the connector 3 and the outside of the preset support all have fillers, and the top of the filler is flush with both sides of the upper end of the groove 1.

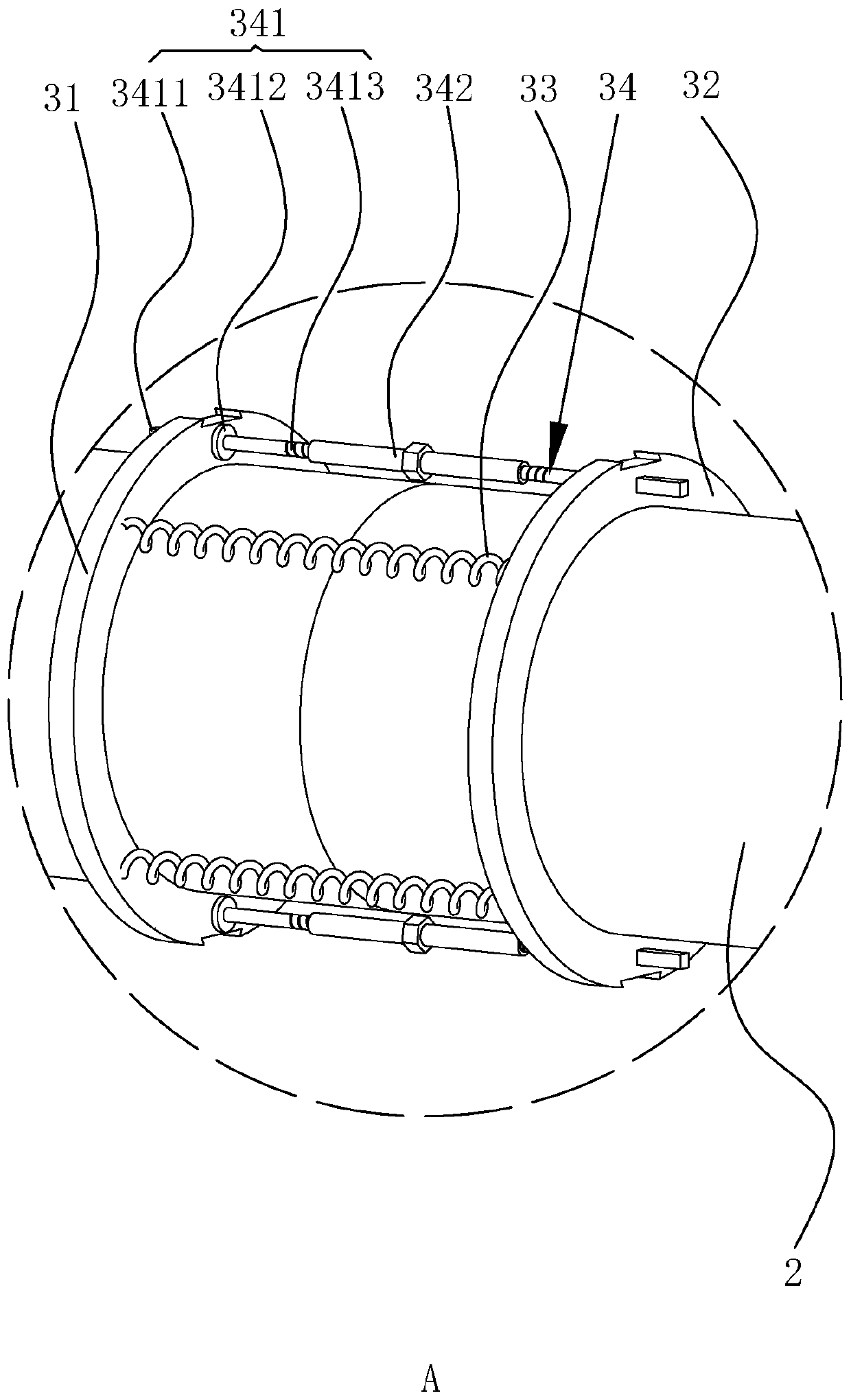

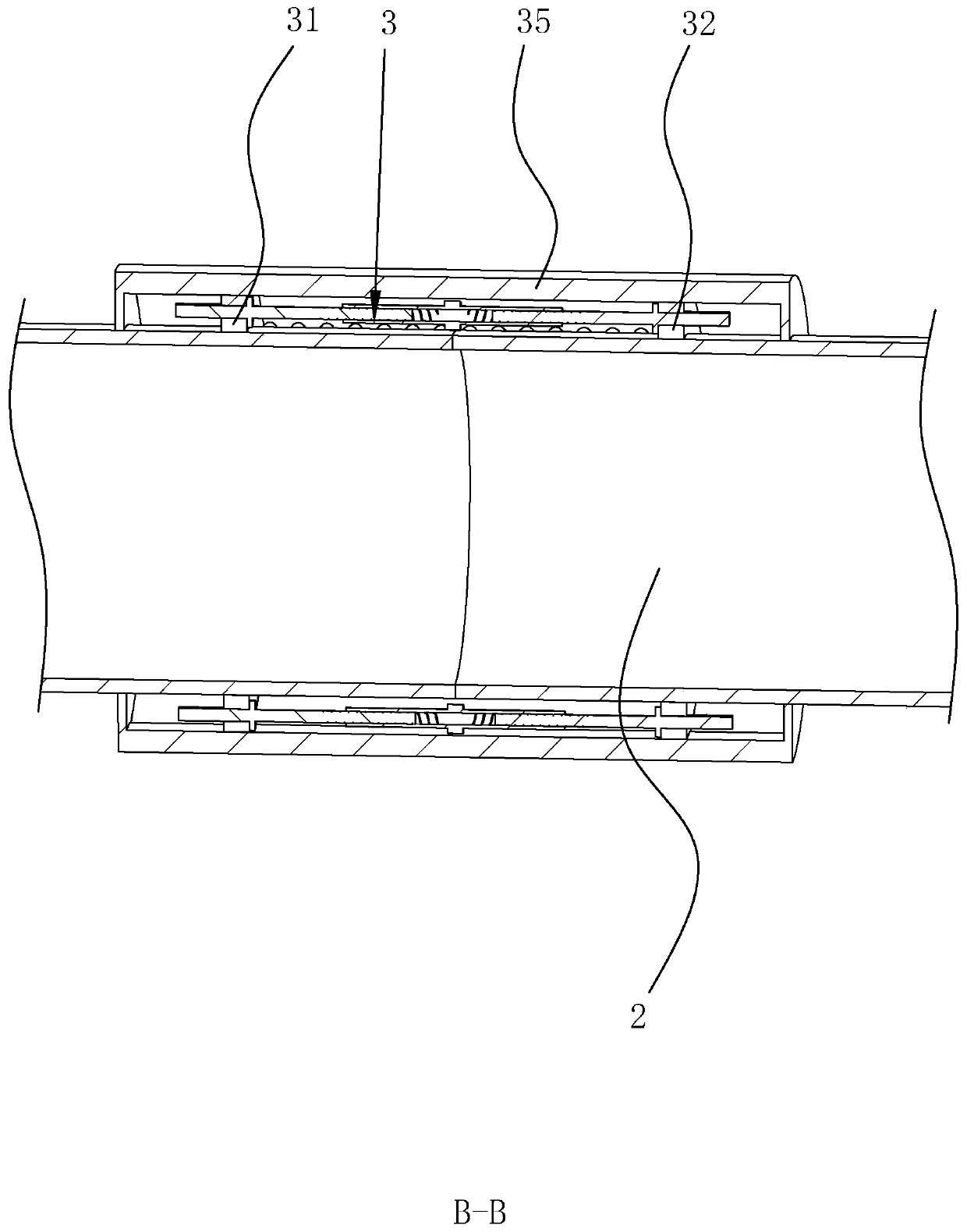

[0056] refer to figure 2 , image 3 , the connector 3 in this embodiment includes a first connecting ring 31, a second connecting ring 32, at least three elastic members 33 and at least two struts arranged between the first connecting ring 31 and the second connecting ring 32 34. The first connecting ring 31 and the second connecting ring 32 are coaxially connected to two adjacent pipes 2 respectively. When the connecting piece 3 is in use, the elastic member 33 has the function of connecti...

Embodiment 2

[0063] This embodiment of the present invention discloses a construction method suitable for the heating pipeline connection structure disclosed in Embodiment 1, which includes the following steps:

[0064] S1: Measurement and setting out: According to the terrain and landform, measure the buried position and direction of the pipeline 2, and mark the setting out, and mark the positions of the prefabricated support 4 and the spreader according to the length and curvature of the pipeline 2.

[0065] S2: Excavation of trench 1: According to the measurement results and the setting-out position, trench 1 is excavated to reach the design elevation and standard width, and trench 1 is opened at a position 225-30cm higher than the preset pipeline with a step groove 11 whose width is greater than that at the bottom .

[0066] S3: Cleaning and tamping: Level the bottom of the tank, clean up the sundries at the bottom of the tank, and tamp the bottom of the tank to a degree of no less tha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap