Ultra-high pressure gas pipeline push-in joint with protection device and operation method thereof

A technology for gas pipelines and protective devices, applied in mechanical equipment, couplings, etc., can solve the problems of cumbersome plugging and unplugging process, poor applicability, low safety and reliability, etc., to avoid high-speed throwing off and splashing, easy to operate and use , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

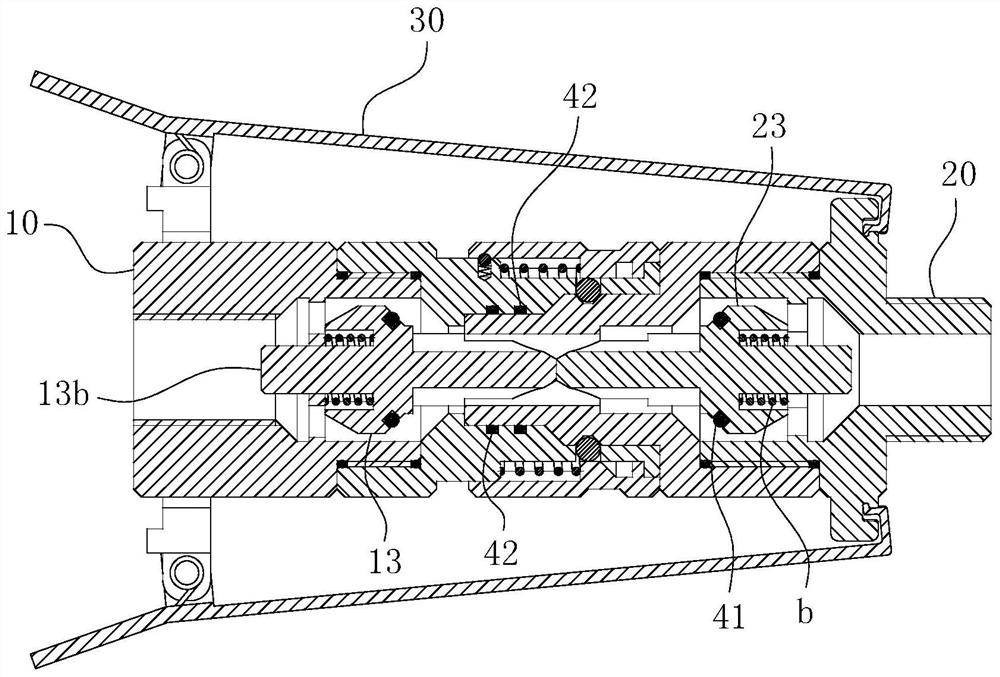

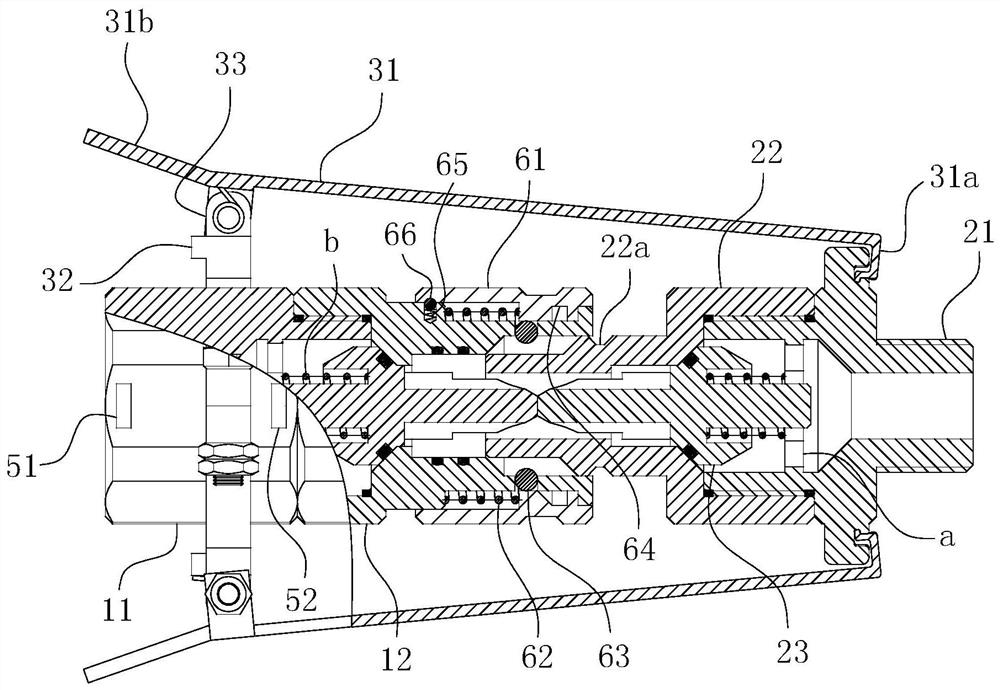

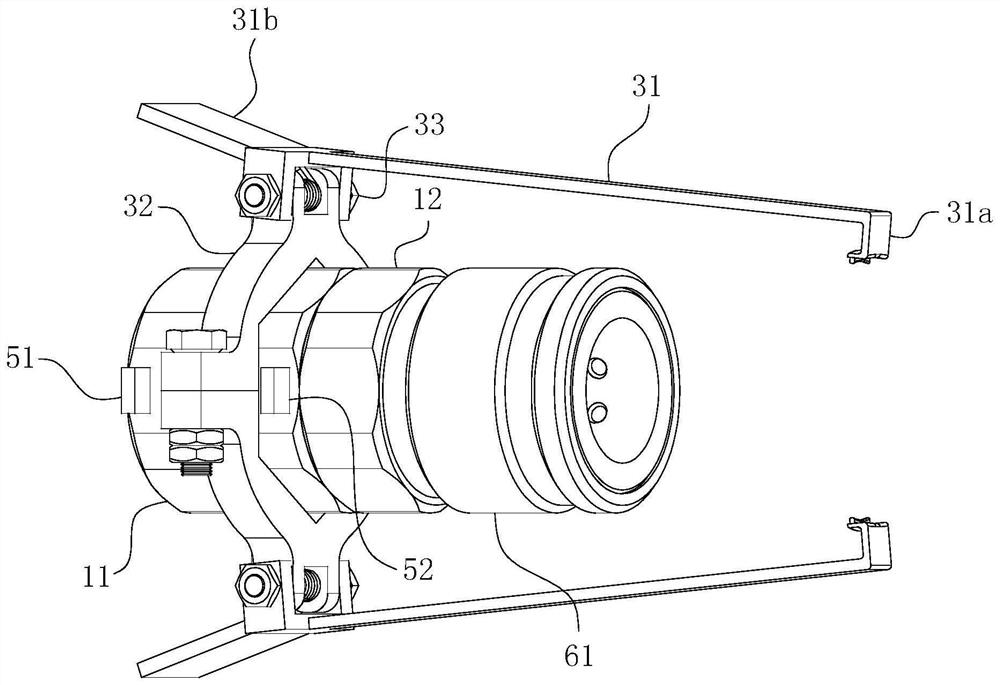

[0048] The concrete implementation structure of the present invention can refer to Figure 1-8 As shown, the main body includes a fixed end assembly 10 , a movable end assembly 20 and a protection assembly 30 , wherein the protection assembly 30 mainly includes a protection card arm 31 , a slip ring 32 , a hinge seat 33 and an anchor point 34 . in such as Figure 1-3 It can be seen from the figure that the slip ring 32, the hinge seat 33 and the protection arm 31 form a combined structure and fit on the fixed end assembly 10, while the anchor point 34 is as shown in Figure 4 The self-contained structure shown fits on the movable end assembly 20 . In actual operation, both the fixed end assembly 10 and the movable end assembly 20 can independently and reliably seal the medium in the connected system during independent placement. When the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com