Circuit board photoelectric exposure machine

An exposure machine and circuit board technology, which is applied to microlithography exposure equipment, photolithographic process exposure devices, optics, etc. Simple, easy to operate, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

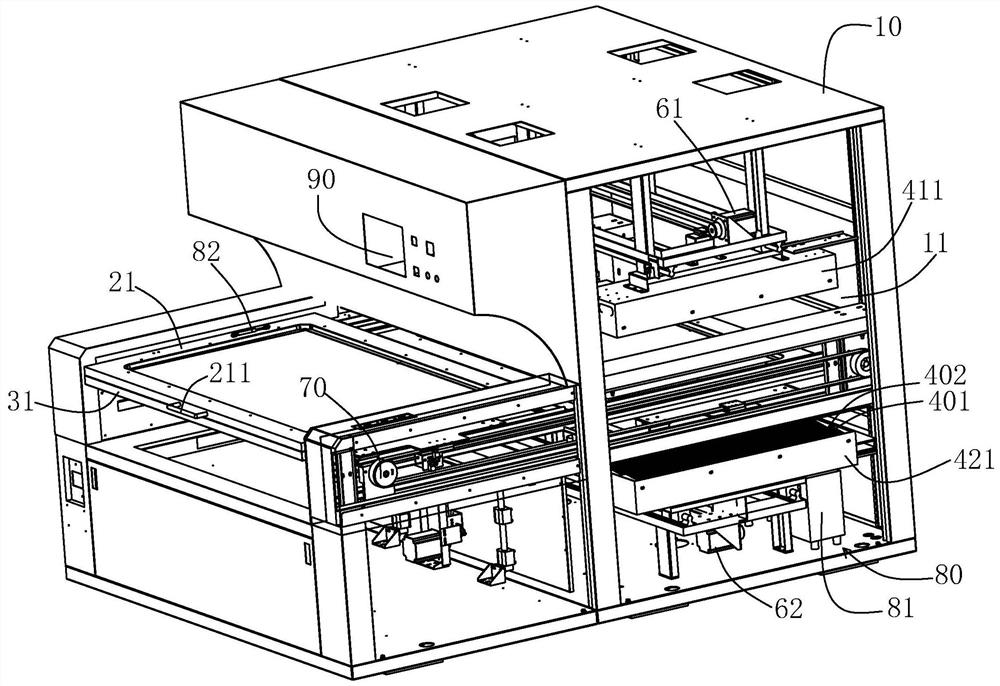

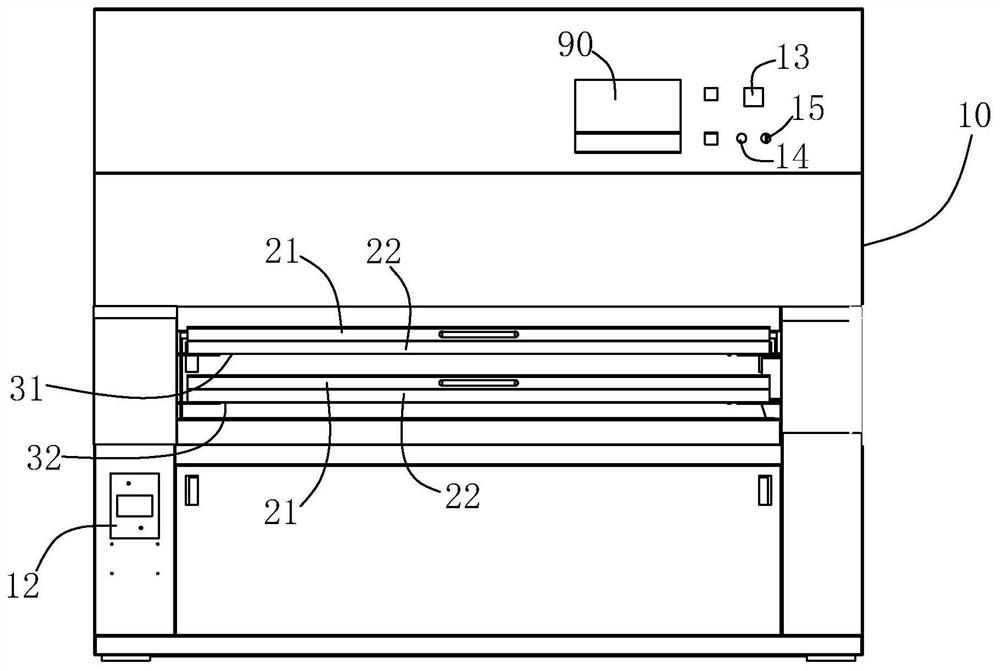

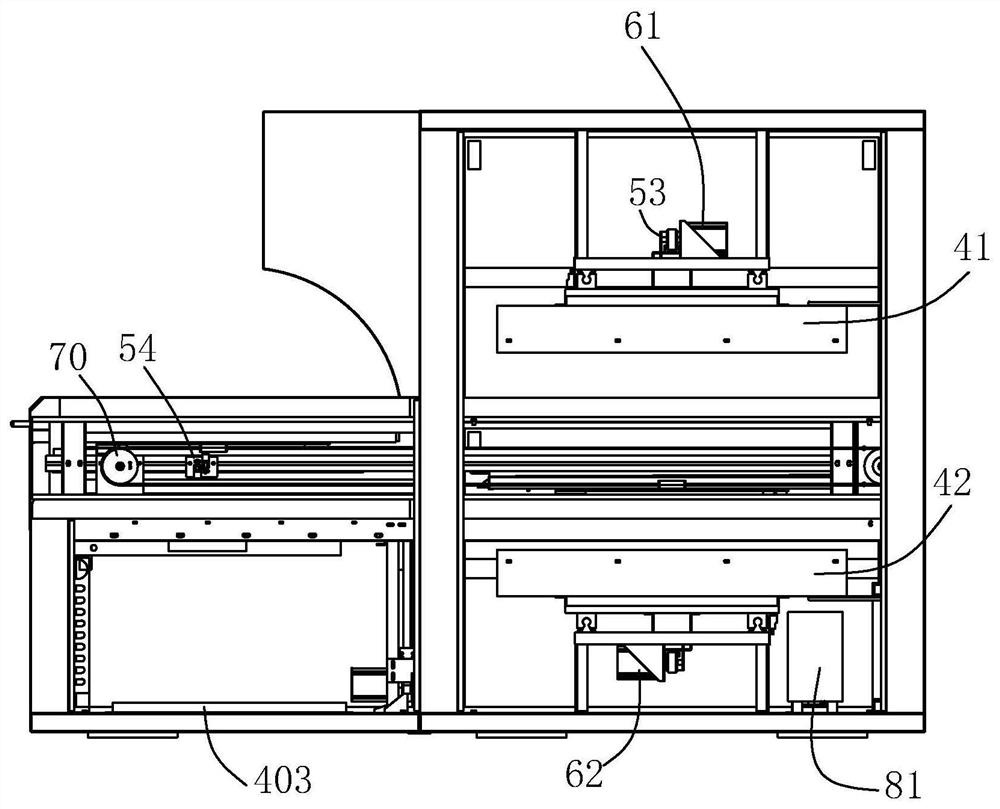

[0029] refer to figure 1 , figure 2 The circuit board photoelectric exposure machine of the present invention includes a body 10, an upper exposure glass 21, a lower exposure glass 22, an upper exposure frame 31, a lower exposure frame 32, an upper exposure lamp 41, a lower exposure lamp 42, a sliding assembly, a servo motor, a transmission Device 70, vacuum assembly 80 and electric control device. Among them, the circuit board photoelectric exposure machine of the present invention can be used for circuit exposure of PCB circuit dry film or wet film, and can be used for rigid and flexible double-sided printed boards.

[0030] Such as figure 1 , figure 2 As shown, the body 10 is composed of two hollow rectangular frames at the front and rear, an operating table is arranged above the front rectangular frame of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com