A patch device and patch method for electronic component production

A technology for electronic components and placement devices, which is applied in the direction of assembling printed circuits with electrical components, electrical components, printed circuits, etc., and can solve the problem of not having a fixed adjustment structure and reducing the application of automatic placement machines for electronic component placement and processing. range, unable to fix the circuit board and other problems, to achieve the effect of wide application range, high placement efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

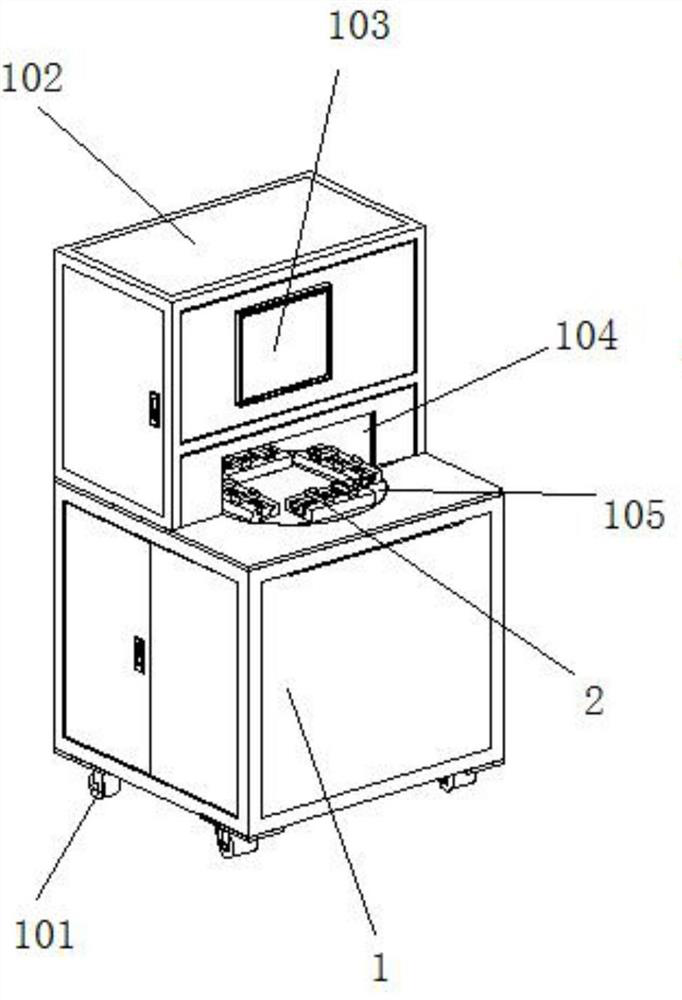

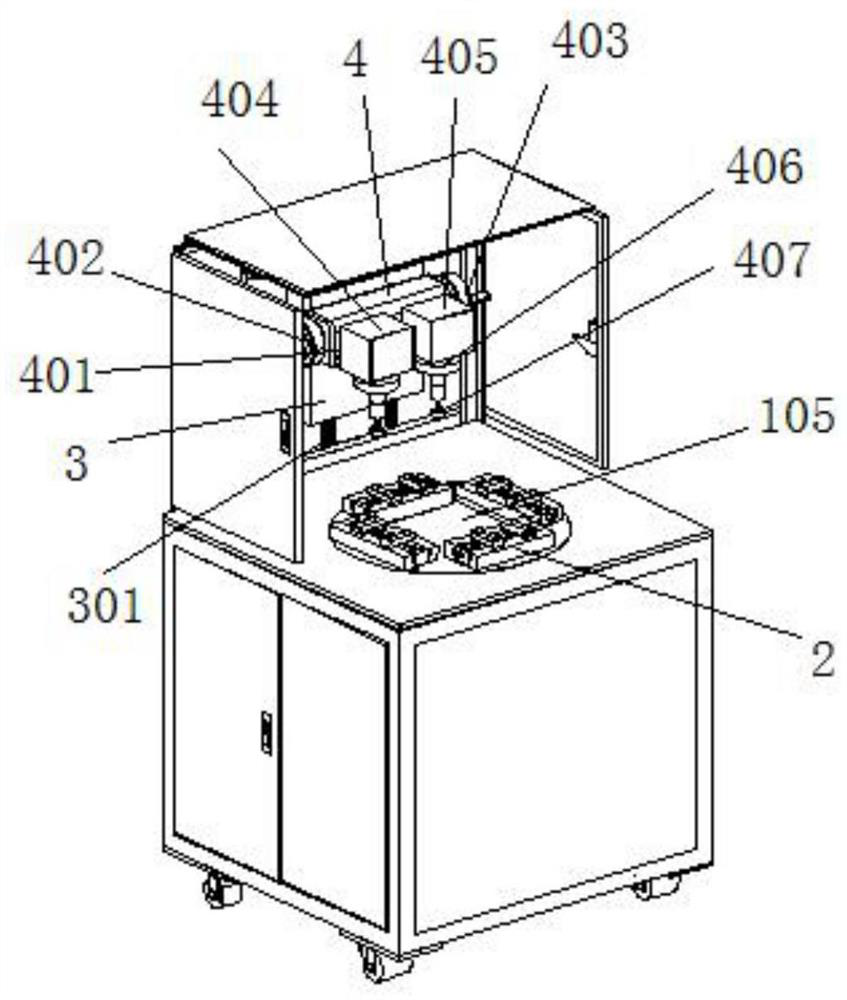

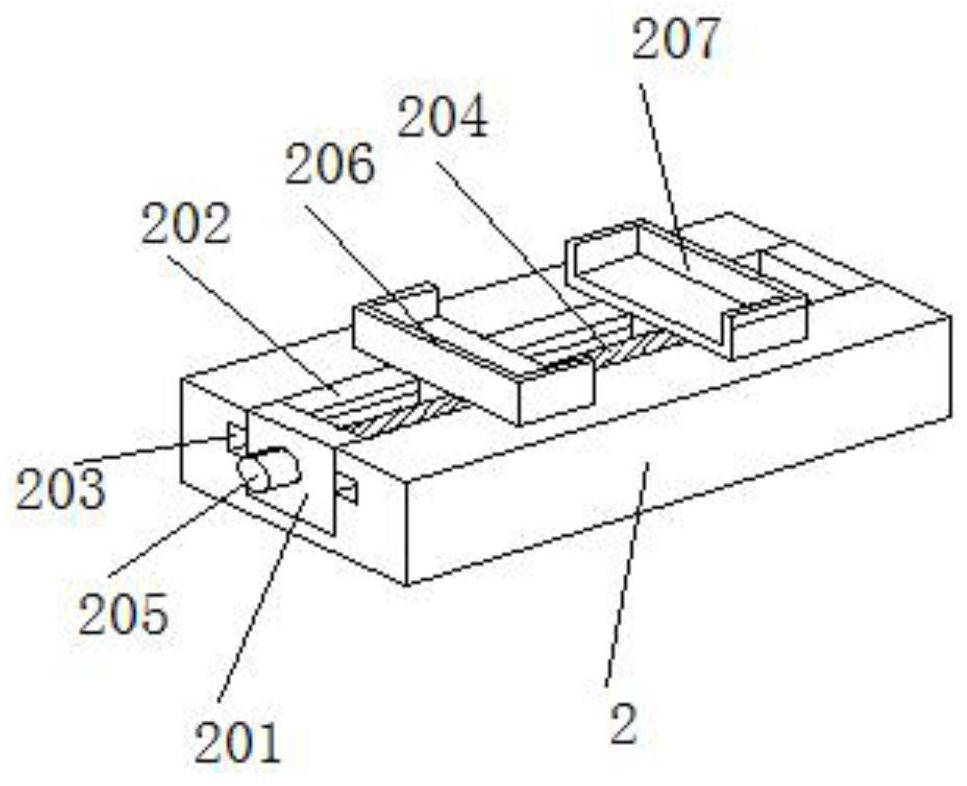

[0031]SeeFigure 1 ~ 7In the embodiment of the present invention, a patch device for the production of electronic components, including a main chassis 1, and a patch chamber 102 is fixed to the top surface of the main chassis 1, the patch chamber 102 inside Sliding on the rear side, the moving gear 3 is slid, and the front side of the moving counter 3 is fixedly disposed, and the lateral fixing frame 4 is disposed side by side, and the main fixing table 404 and the sub-fixing table 405 are provided side by side. The main fixing ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com