Complex of lactoferrin and silica, process for preparing and compositions for oral hygiene

A technology of silicon dioxide and lactoferrin, applied in the field of oral hygiene compositions, can solve the problems of oxidative degradation, poor compatibility, low bioavailability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0052] Preparation of the composition shown in Table 1 (% by weight of the total composition):

[0053] Table 1

[0054]

[0055]

[0056] (*)Compare

[0057] Hydrophilic silica: The specific surface area is about 200m 2 / g (BET area, measured according to standard ISO 9277-2010) of hydrophilic fumed silica (commercial product Aerosil TM 200 from Evonik);

[0058] Rice husk silica: The specific surface area is about 550m 2 / g (BET area, measured according to standard ISO 9277-2010) and a density of about 0.050 g / cm 3 Silica in the form of an aerogel.

[0059] Rice husk silica and lactoferrin are compounded in advance by the following method. The preparation of rice husk silica was as described in Example 1 of WO2016 / 193877, except that, after obtaining the silica sol-gel, it was added to lactoferrin, and then as in the same Example 1 The supercritical CO 2 Drying, with the difference that the silica sol-gel with added lactoferrin is treated in an autoclave at a te...

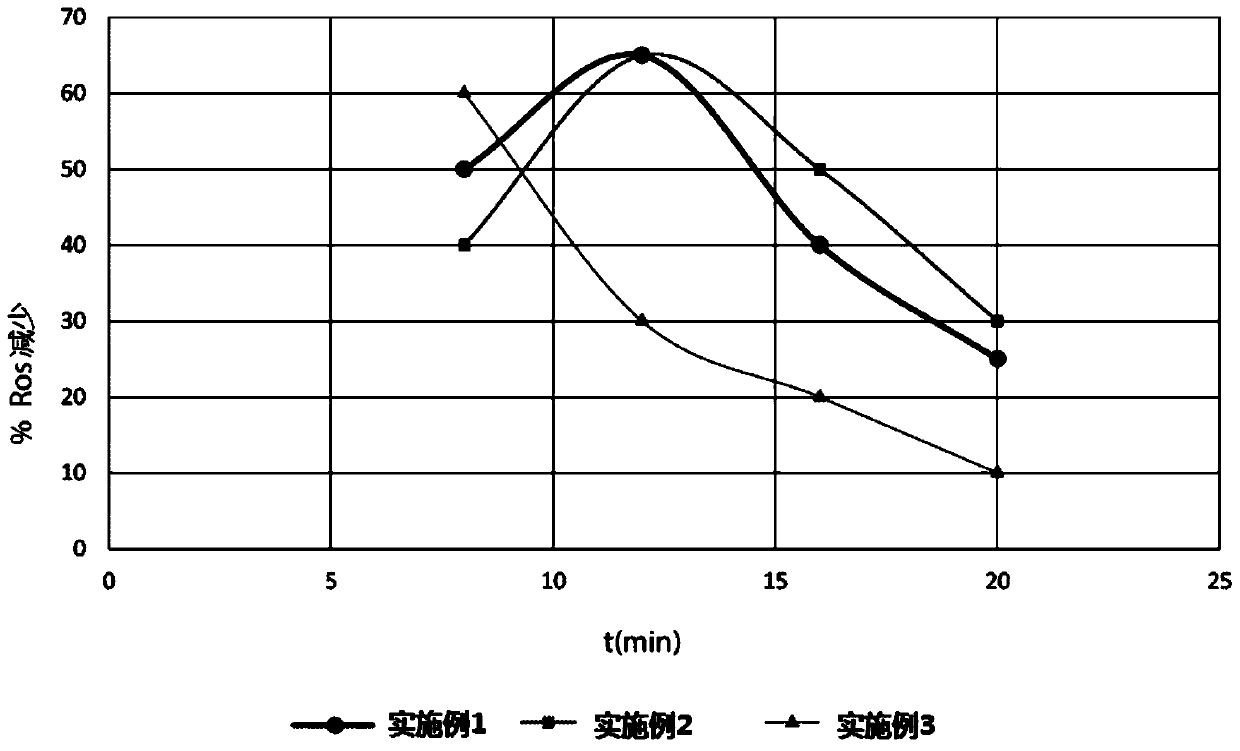

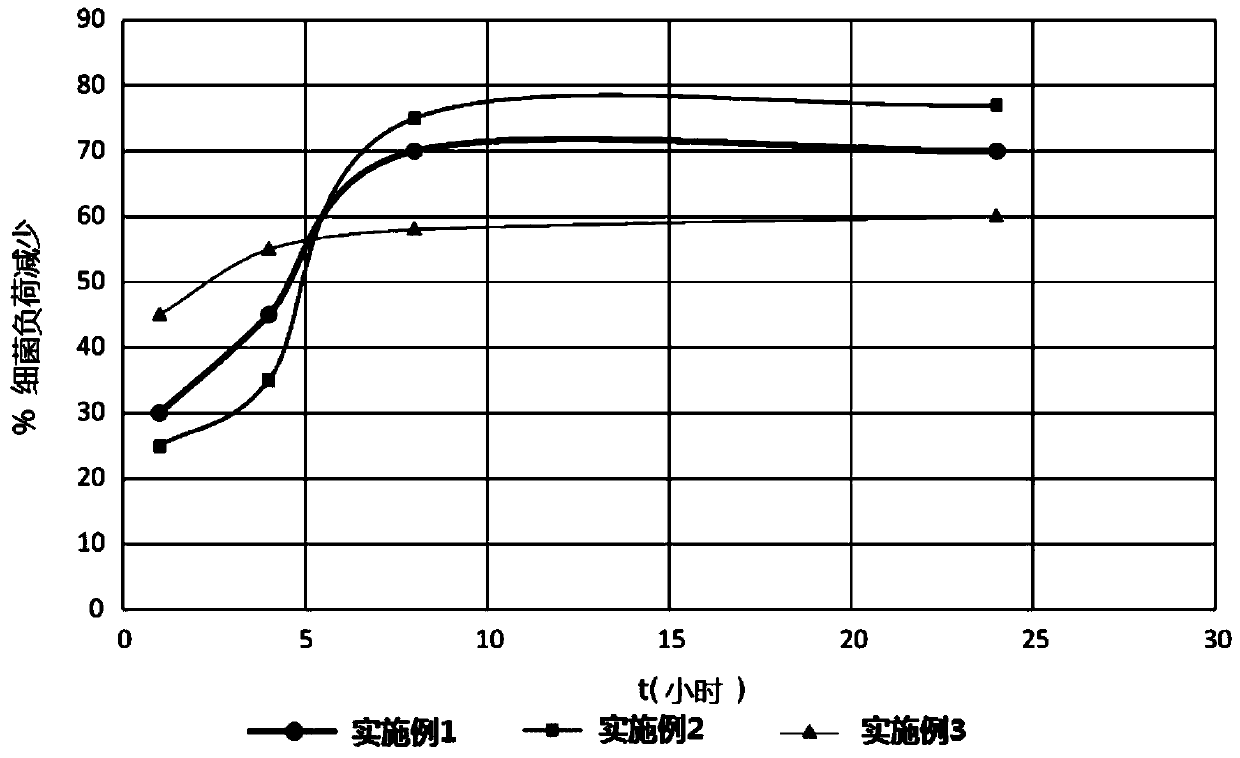

Embodiment 4-6

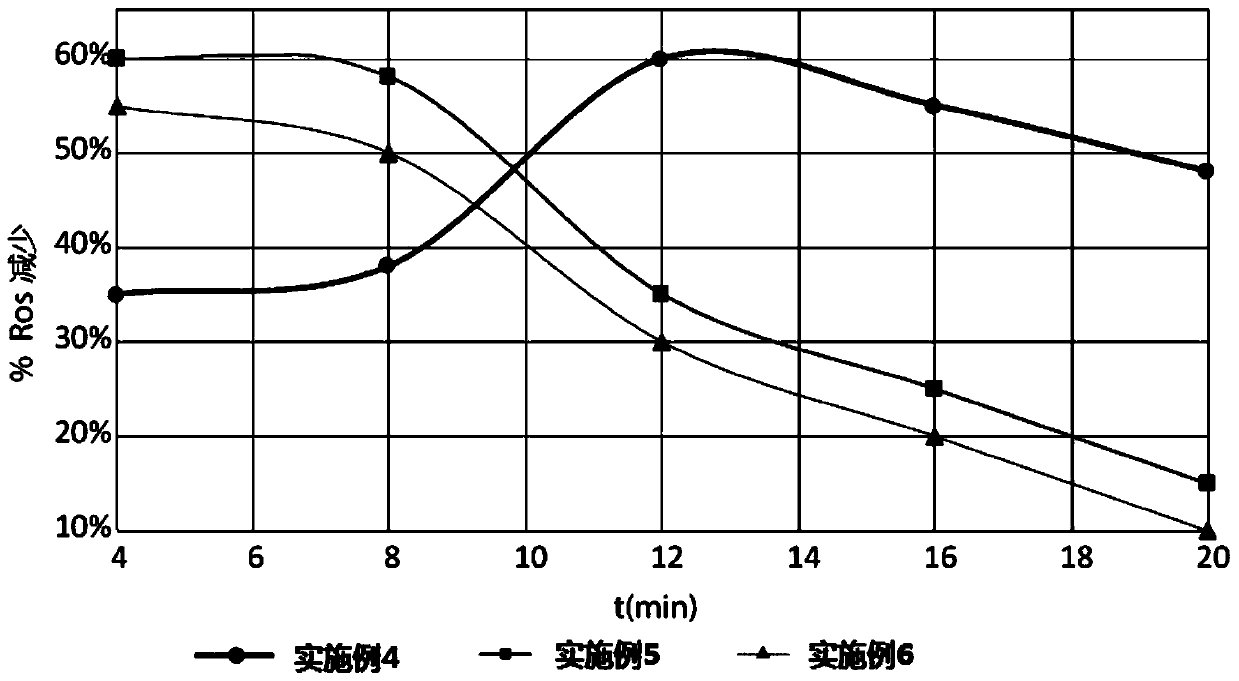

[0086] Examples 2 and 3 were repeated under the same conditions with the same ingredients as described above (Examples 4 and 5). Another comparative example (Example 6) was carried out again with the same procedure and the same ingredients, in which lactoferrin was simply mixed with hydrophilic silica, i.e. no complex according to the invention was prepared, in which the silica Prepared in sol-gel form, with lactoferrin added, then dried. Compositions are reported in Table 4 (% by weight of total composition):

[0087] Table 4

[0088] Example 4 5(*) 6(*) glycerin 51.0 74.0 51.0 water 15.0 25.0 15.0 Hydrophilic silica 30.0 -- 33.0 Rice husk silica 3.0 -- -- Lactoferrin 1.0 1.0 1.0

[0089] (*)Compare

[0090] The antioxidant and antimicrobial properties of these compositions were verified and the efficacy over time was evaluated as described in Examples 1-3.

[0091] The results are reported in the table below, where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com