Oxygen feeding refining method for molten iron and top-blow lance

A technology for sending oxygen and molten iron, applied in the manufacture of converters, etc., can solve problems such as inability to increase the flow rate, and achieve the effect of a large variable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

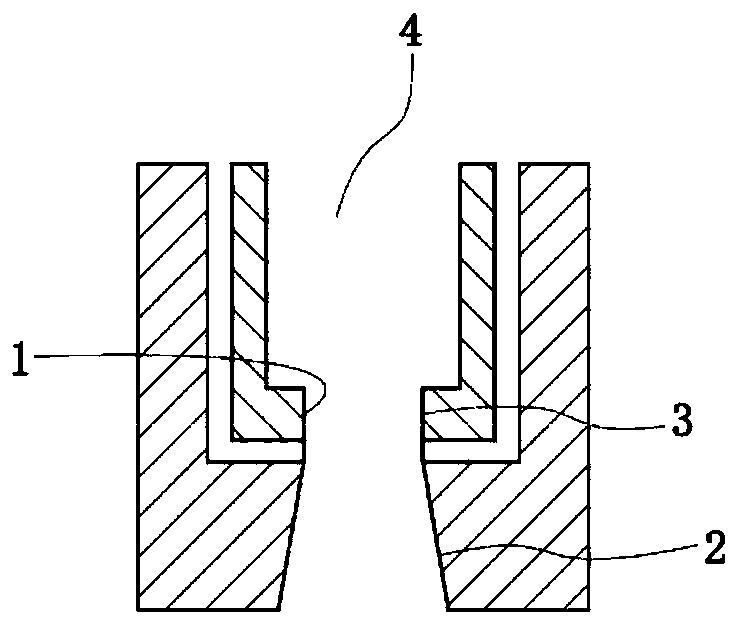

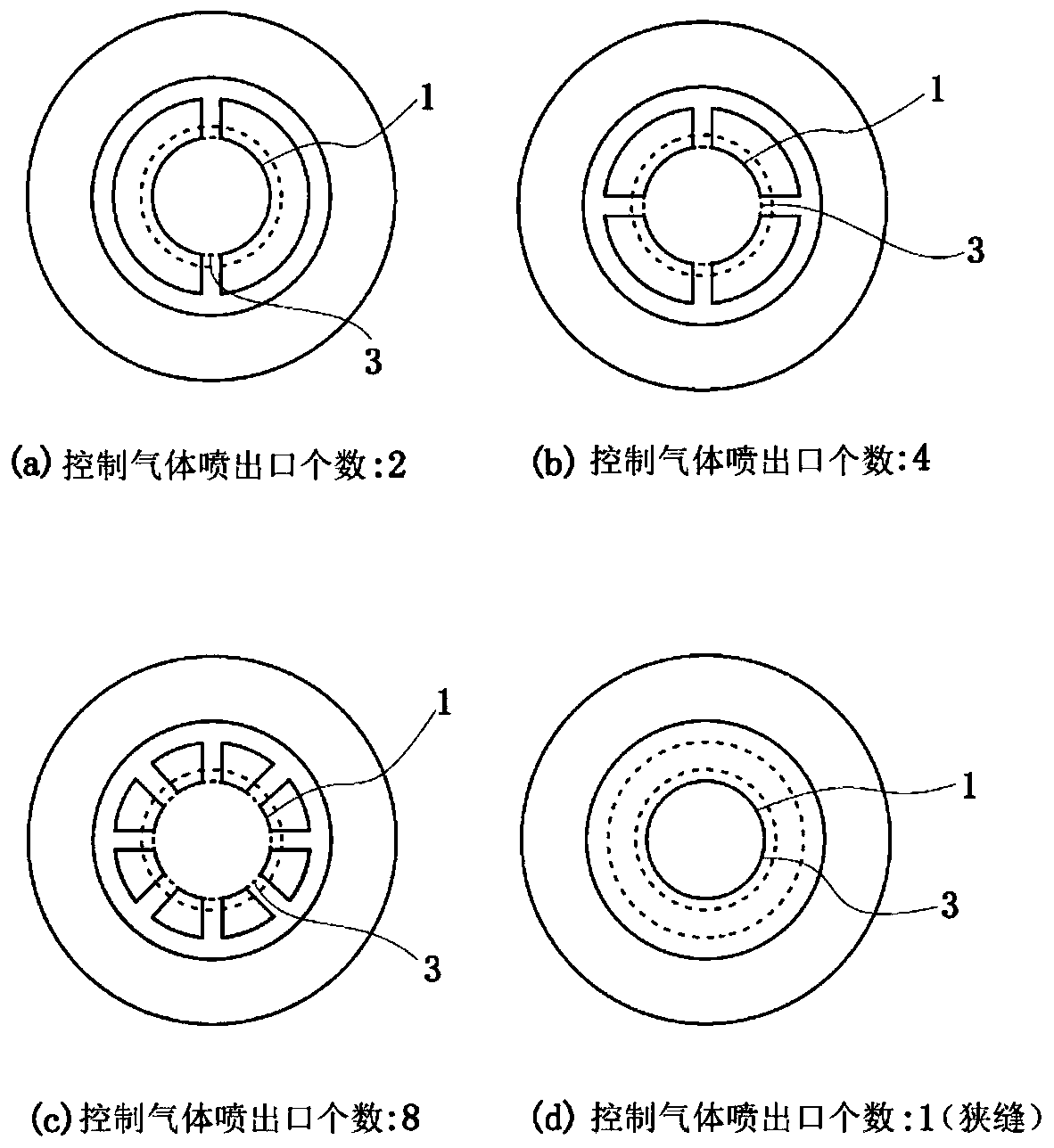

Method used

Image

Examples

Embodiment

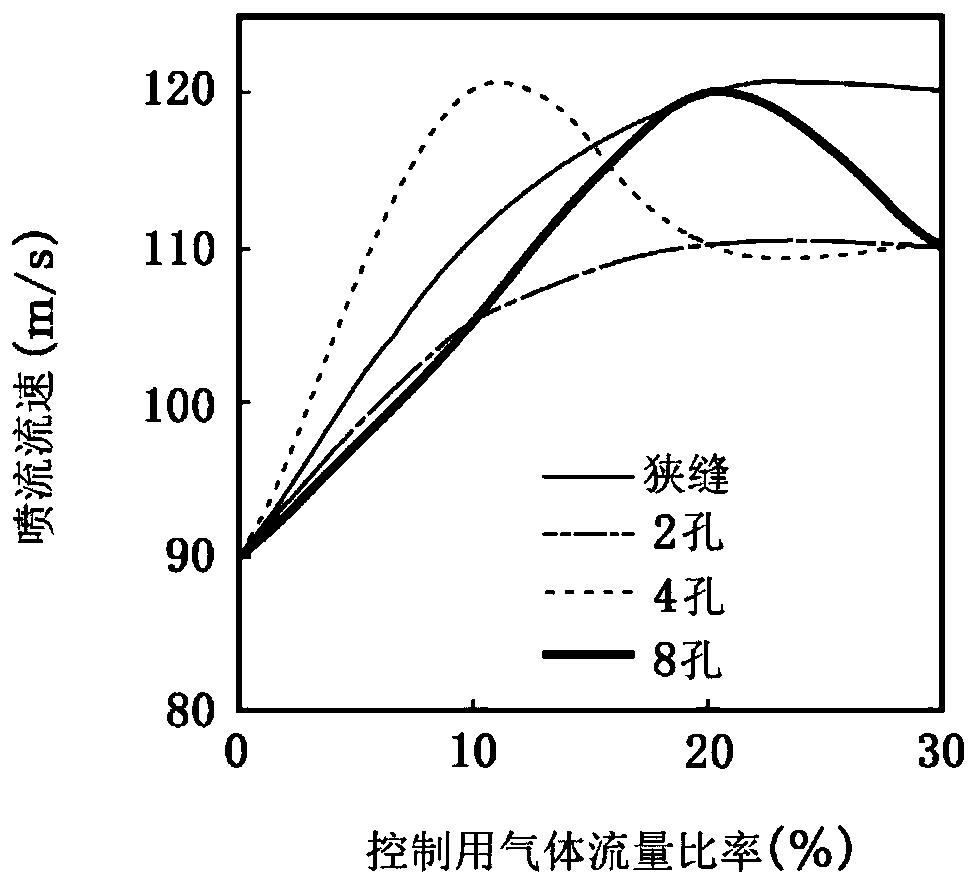

[0115] Hereinafter, an actual example in which the oxygen-feeding refining method for molten iron of the present invention is applied to an industrial-scale converter decarburization treatment will be described.

[0116] In a 300t-scale top-bottom blowing converter facility, the decarburization treatment of molten iron was performed by changing the spray nozzle styles of various top-blowing lances, and the effects on the amount of dust generation, iron yield, and slag generation status were investigated. After the molten iron is received in the blast furnace and transported to the ironworks in the iron mixing car containing the iron scraps containing the weight scraps in advance, a predetermined amount of the molten iron is poured into the molten iron ladle, and a mechanical stirring type molten iron desulfurization device is used in the molten iron ladle. Carry out desulfurization treatment. After the desulfurized slag was discharged from the ladle, molten iron was charged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com