A hydraulic closed system motor characteristic test bench

A closed system and characteristic testing technology, which is applied in fluid pressure actuation system testing, servo motor, mechanical component testing, etc., can solve the problems of long development cycle and high cost, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

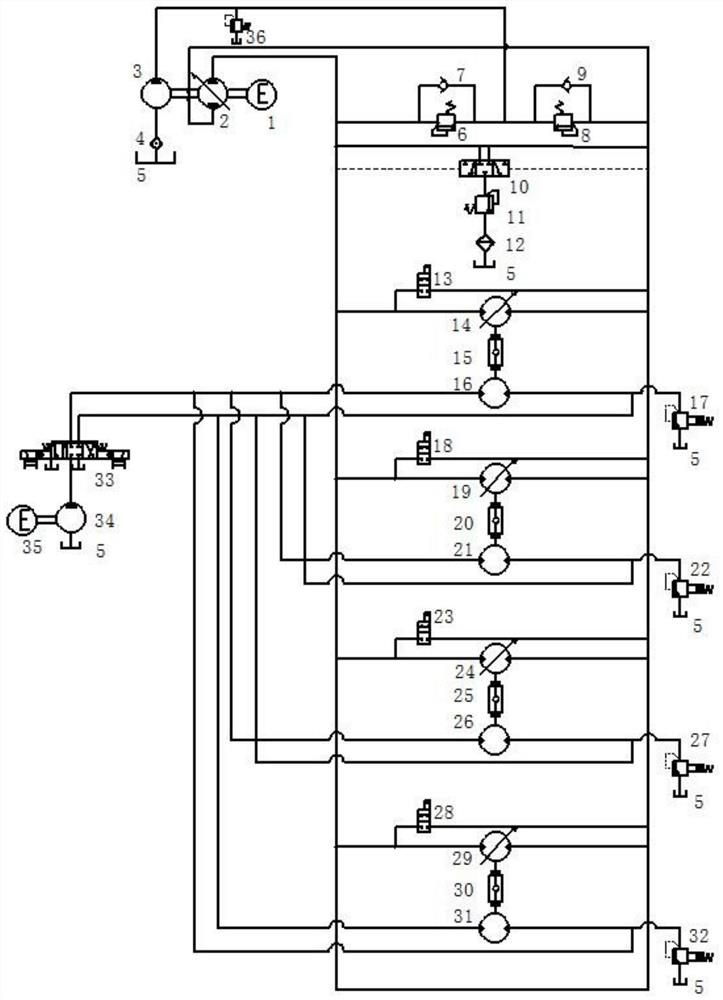

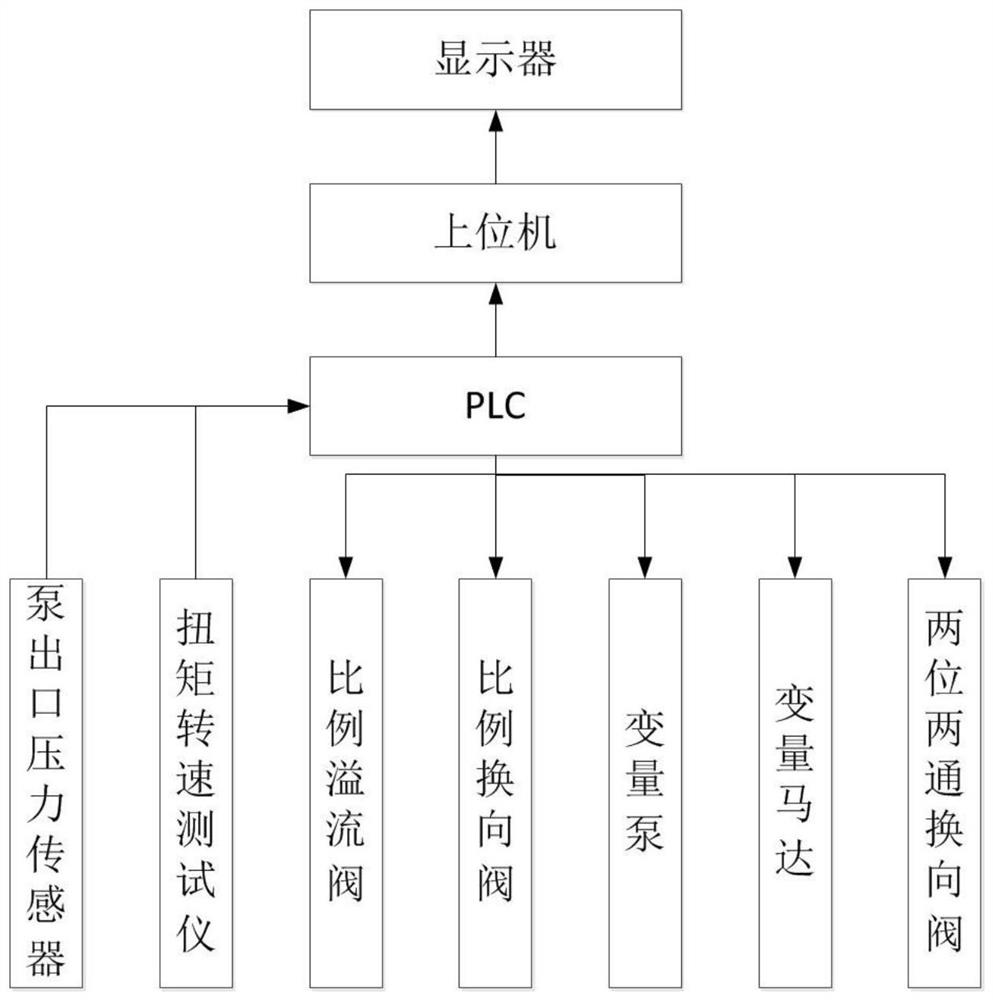

[0023] see figure 1 , A hydraulic closed system motor characteristic test bench mainly includes two parts: one is the hydraulic closed system circuit, and the other is the load loading circuit.

[0024]The hydraulic closed system circuit includes power components, control components, executive components, auxiliary components and measuring components. The power components include an electric motor a, a piston variable displacement pump 2 and an oil charge pump 3 . The power source of the system is the electric motor a, and the rated speed of the electric motor a is 1500-2000r / min, which can be matched according to the rated speed of the selected plunger variable pump 2. For the second, one shaft drives the plunger variable pump 2, and the other shaft drives the charge pump 3. There is no variable transmission ratio device between the transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com