A large-scale glass fiber reinforced plastic wind turbine shroud positioning and punching tool

A technology of wind power generators and glass fiber reinforced plastics, applied in metal processing, etc., can solve the problems of inconvenient loading and unloading, inability to enter the processing operation of the shroud, little change in size and shape of the shroud, etc., and achieve the effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the techniques, creative characteristics of the present invention, it is easy to understand that the present invention is further illustrated in connection with the specific embodiments.

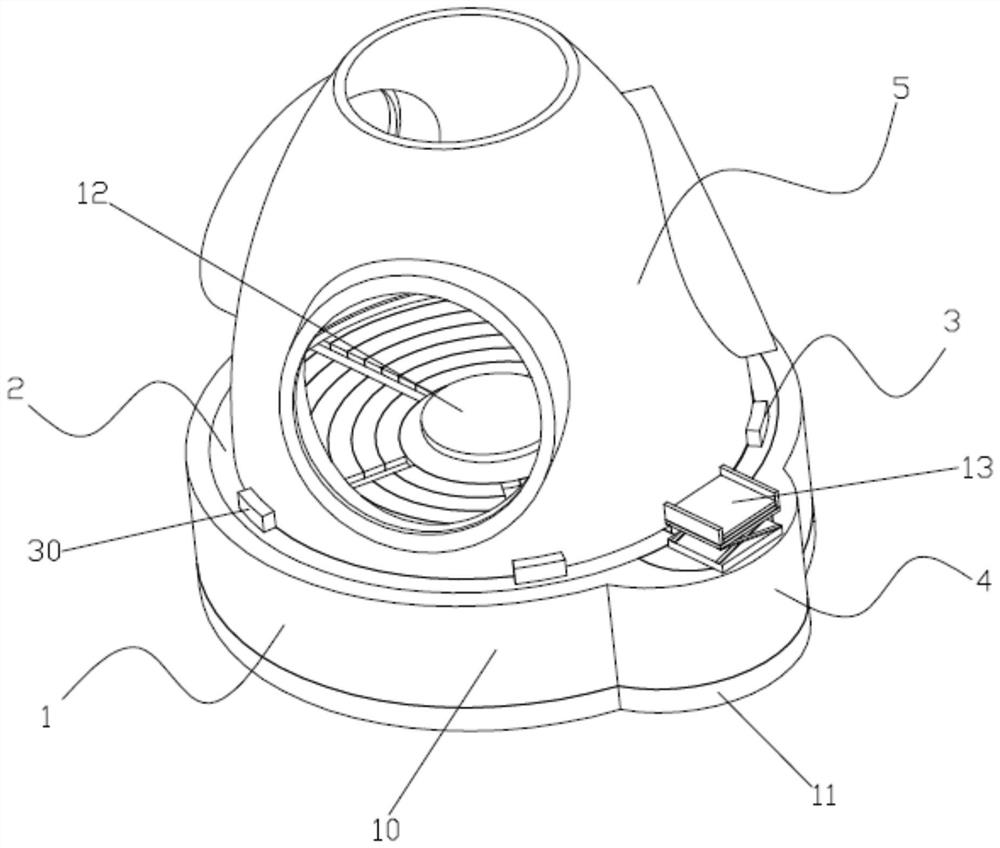

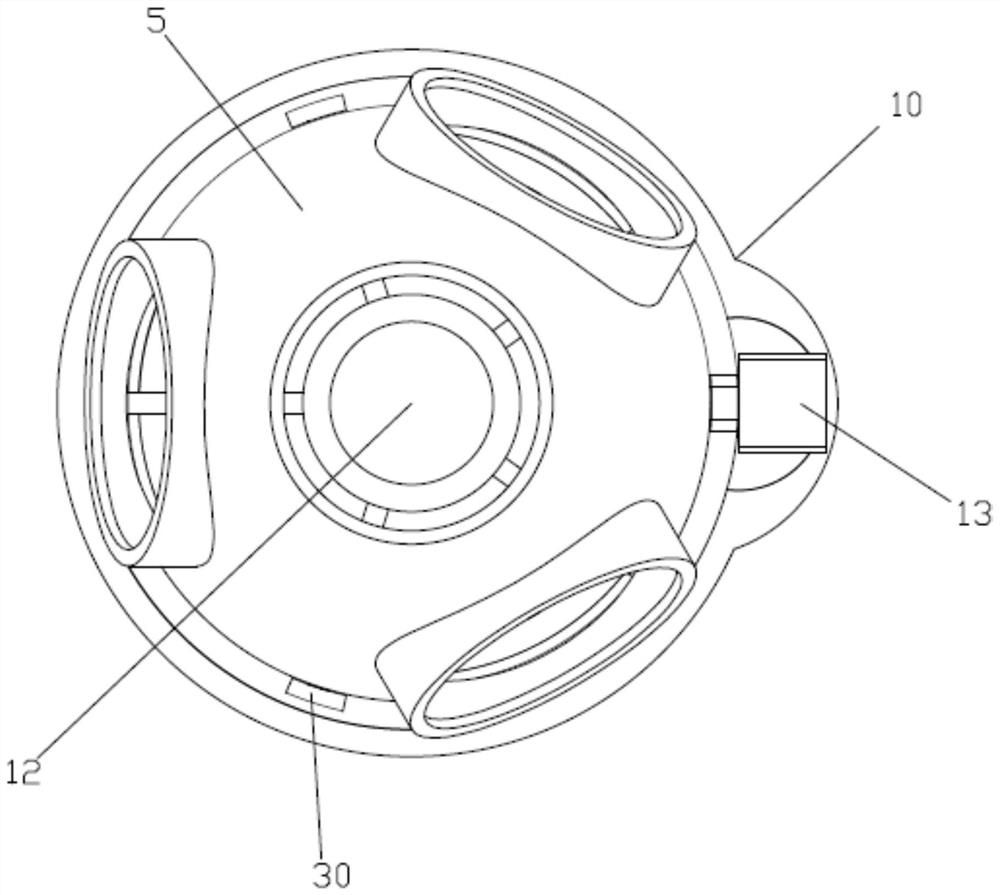

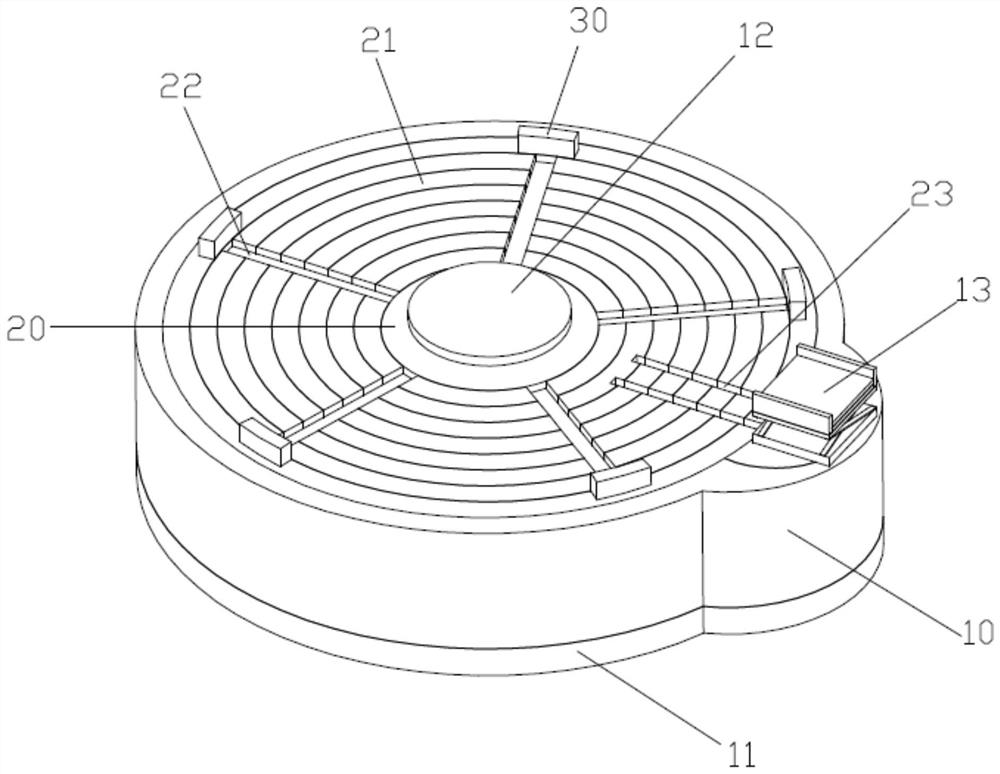

[0030] like Figures 1 to 12 As shown in A large fiberglass wind turbine shroud alignment punch tooling, comprising a housing assembly, the tray assembly 2, the fixing means 3 and the drive mechanism 4, the housing assembly includes a housing 10 and fixedly connected to the housing 11 on the bottom plate 10, the tray assembly 2 comprises a fixed disc 20 and the rotating ring disk 21, the rotating ring disk 21 is provided with a plurality of, and sequentially sleeved slidably connected together and to each other, the stationary disk 20 by fixing strut 14 is fixedly connected to the bottom plate 11 within the housing 10 and located at the center of the rotating ring disk 21 rotatably connected between the fixed disc 20 and the housing 10;

[0031] The fixing means 3 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com