A Palletizing Planning Method for Bags Facing Fully Automatic Loading

A fully automatic, bagged technology, which is applied in the direction of object stacking, loading/unloading, conveyor objects, etc., can solve the problems of long time-consuming manual operation process, labor cost, and low efficiency, so as to facilitate the transportation of goods And subsequent unloading, loading and palletizing specifications, convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

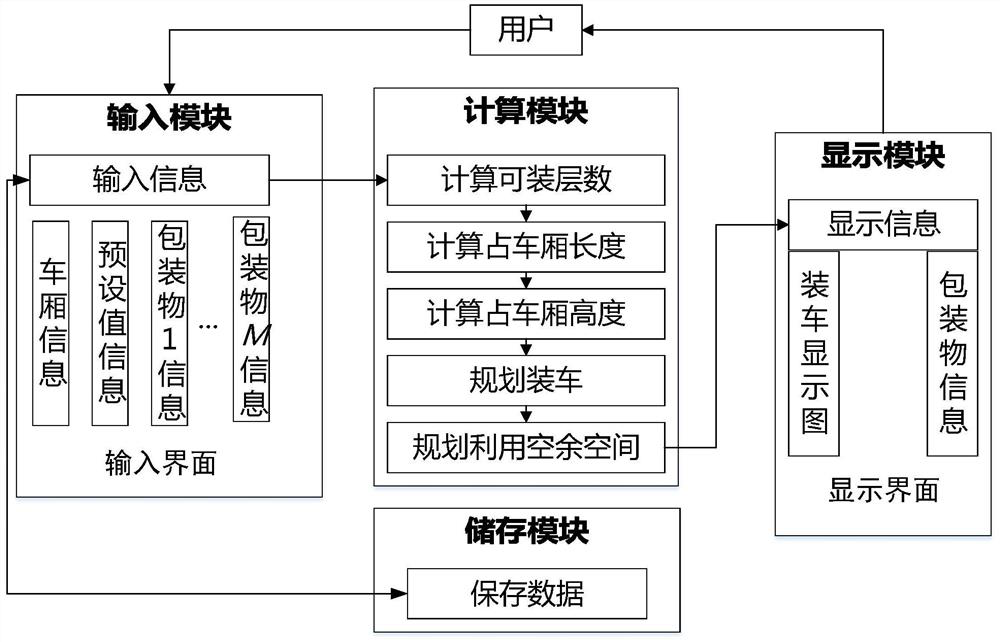

[0047] A bag palletizing planning system for fully automatic loading, such as figure 1Shown include: input module, storage module, computing module and display module. The input module is connected with the calculation module and the storage module; the calculation module is connected with the input module and the display module; the storage module is only connected with the input module; the display module is only connected with the calculation module; the user inputs information through the input module, and the display module loads the corresponding vehicle The plan is displayed for feedback to the user.

[0048] The input module is for the system to enter the information required for the loading plan, and input the length, width, and height parameters {X, Y, Z} of the carriage in the user interface, and the length, width, and height information of M types of bags {a 1 ,b 1 ,c 1 ,a 2 ,b 2 ,c 2 ,...,a i ,b i ,c i ,...,a M ,b m , c m} and the corresponding planned...

Embodiment 2

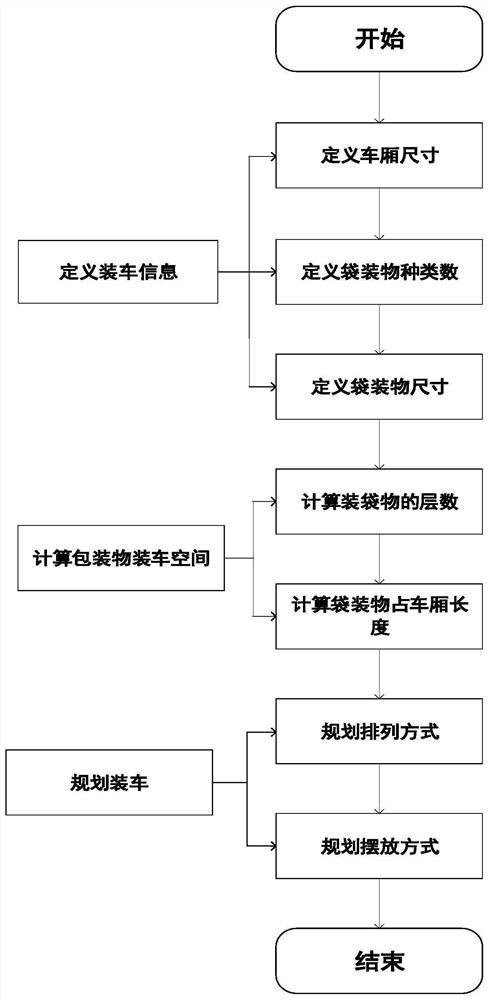

[0054] The flow of a planning method for bagged goods palletizing for fully automatic loading is as follows: image 3 Shown:

[0055] Step 1: Define loading information

[0056] Among them, the definition of loading information is aimed at bags of common specifications in the market (including 20kg, 30kg, 40kg, 50kg, 65kg, etc.), approximate the filled bag as a cuboid, save its length, width, height and other information to the system, and define the compartment at the same time Length, width, height parameters {X, Y, Z}, bag length, width, height {a 1 ,b 1 ,c 1 ,a 2 ,b 2 ,c 2 ,...,a i ,b i ,c i ,...,a M ,b M ,c M} and information such as the quantity M of the type of loading bag for planning loading. Then the volume V of the i-type bag i for:

[0057] V i =a i b i · c i

[0058] where a i , b i , c i are the length, width and height of the i-th bag type, and 1≤i≤M.

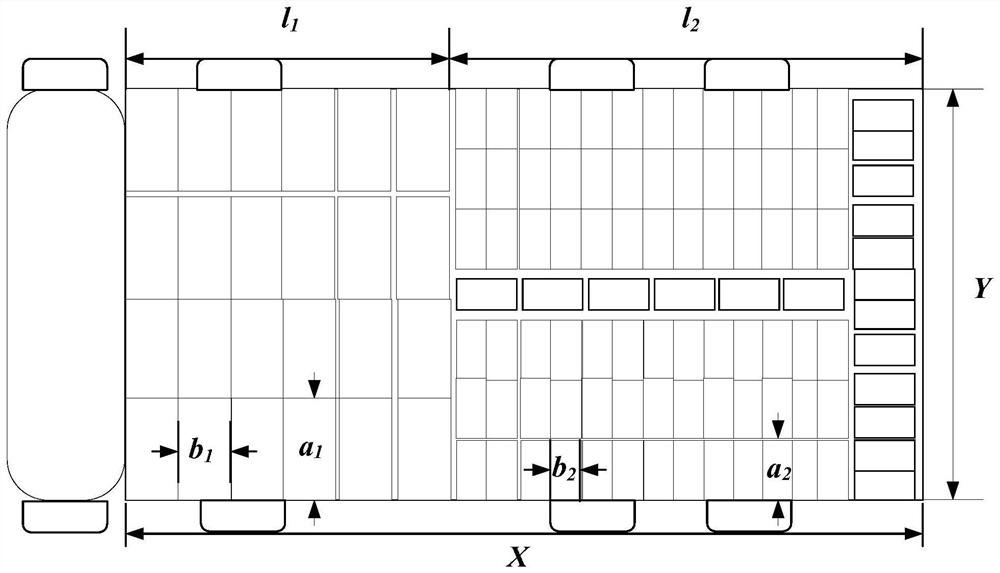

[0059] The actual loading situation is as follows figure 2 As shown, the largest out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com