Permanent magnet motor rotor punching sheet with high reluctance torque

A technology of rotor punching and permanent magnet motor, which is applied in the direction of motor, magnetic circuit, electric components, etc., can solve the problem that the double-one structure cannot be flexible in the adjustment of the magnetic circuit structure, the permanent magnet magnetization effect is not good, and the torque density of the motor is reduced. and other problems, to achieve the effect of improving NVH performance, improving saliency rate and weak field speed expansion ability, and improving torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

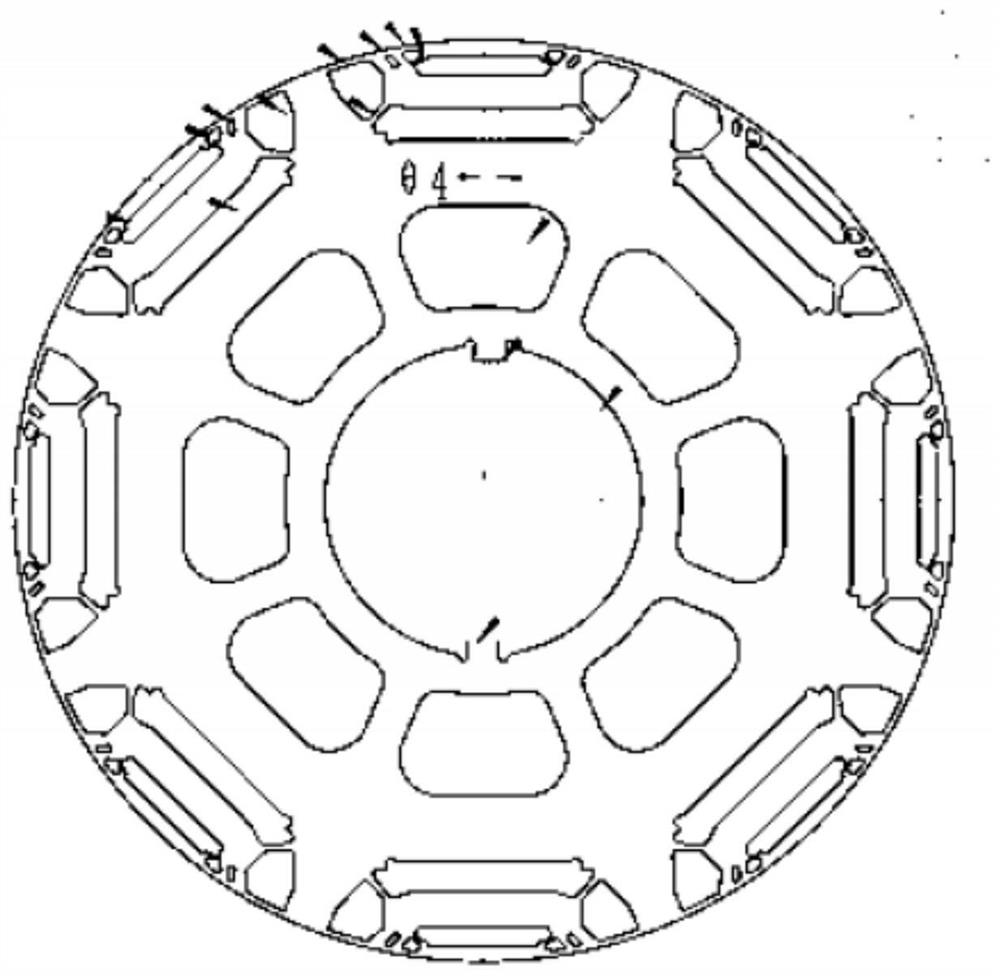

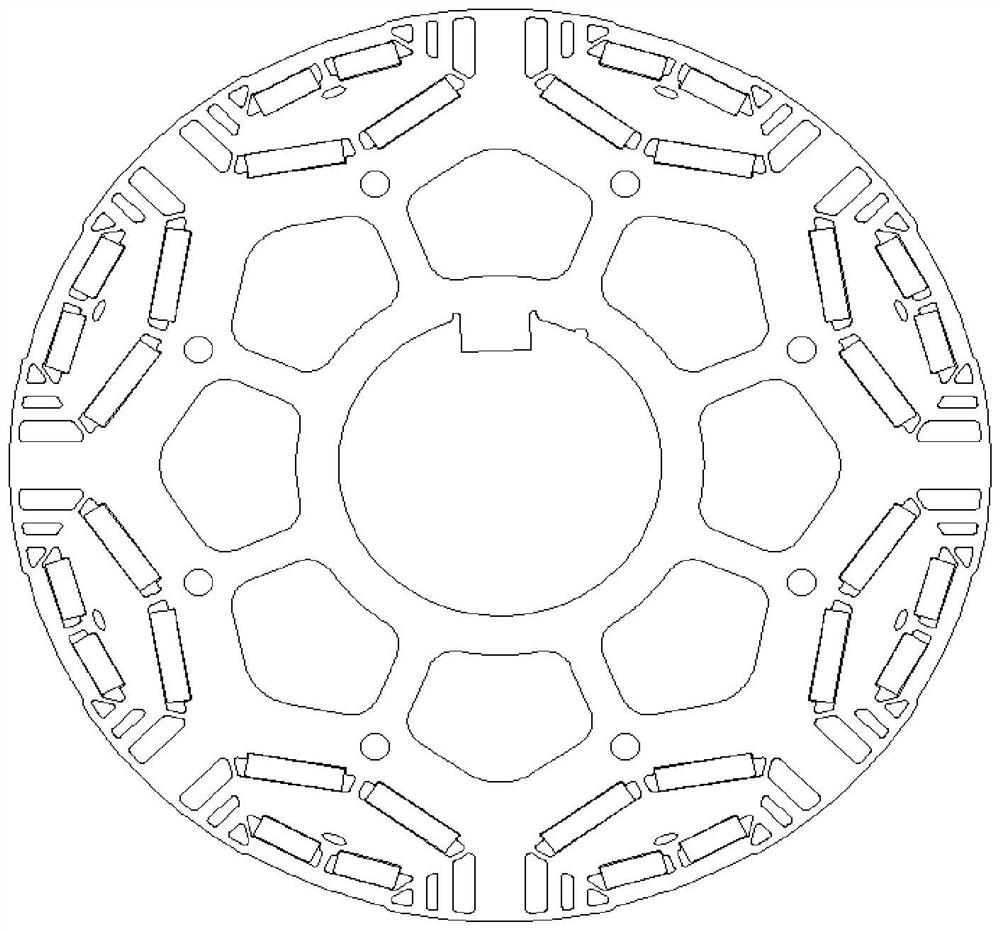

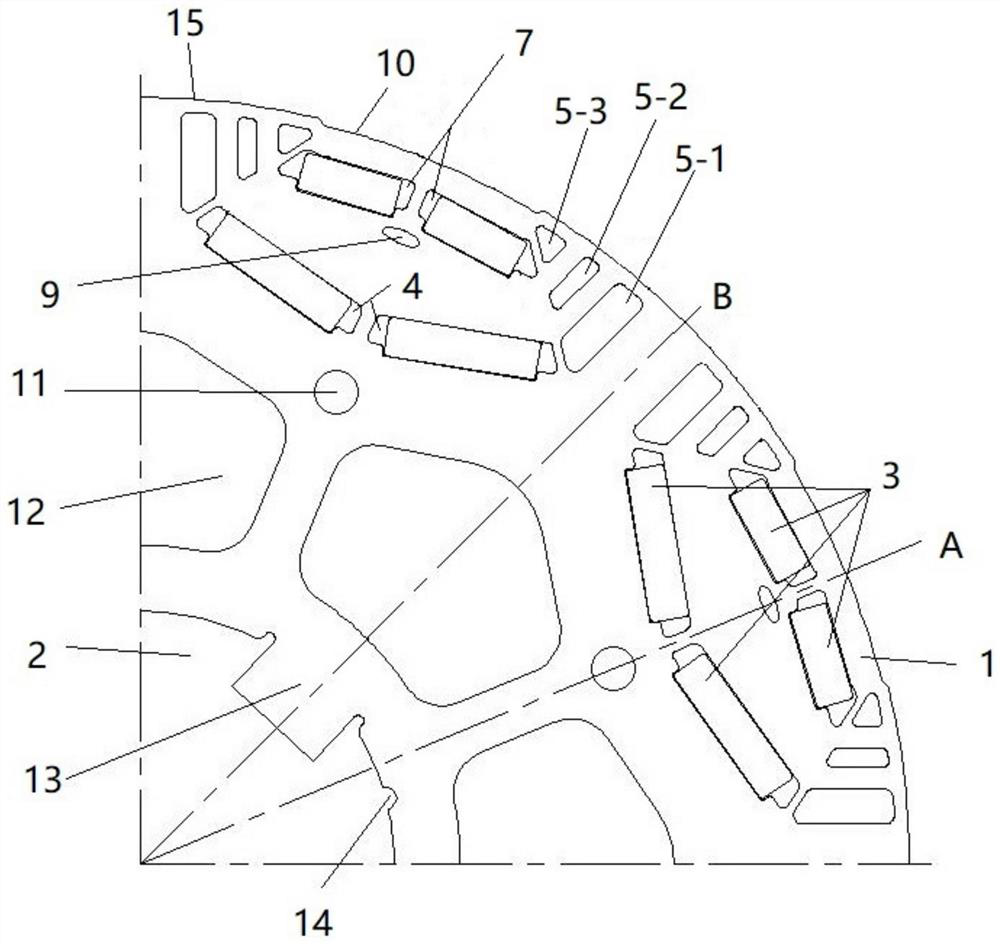

[0032] refer to Figure 2 to Figure 10 As shown, a permanent magnet motor rotor punch with high reluctance torque includes a rotor punch body 1 and a shaft hole 2 located in the center of the rotor punch body. The rotor punch body is divided into several unit magnetic poles. There are several magnetic steel groove groups on the magnetic pole, and the magnetic steel groove group includes a first V-shaped magnetic steel groove 4 symmetrically arranged about the center line A of the d-axis; A magnetic isolation hole 5-1, a second magnetic isolation hole 5-2, and a third magnetic isolation hole 5-3, the first, second and third magnetic isolation holes are arranged parallel to each other and spaced apart. The distances between the second and third magnetic isolation holes and the center line of the d-axis are from far to near; the outer edges of the first, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com