Composite regulator for flotation of graphite in waste lithium ion battery and recovery method of graphite in waste lithium ion battery

A compound regulator and lithium-ion battery technology, which is applied in battery recycling, waste collector recycling, recycling technology, etc., can solve the problems of low carbon grade and high impurities, and achieve the effect of improving grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

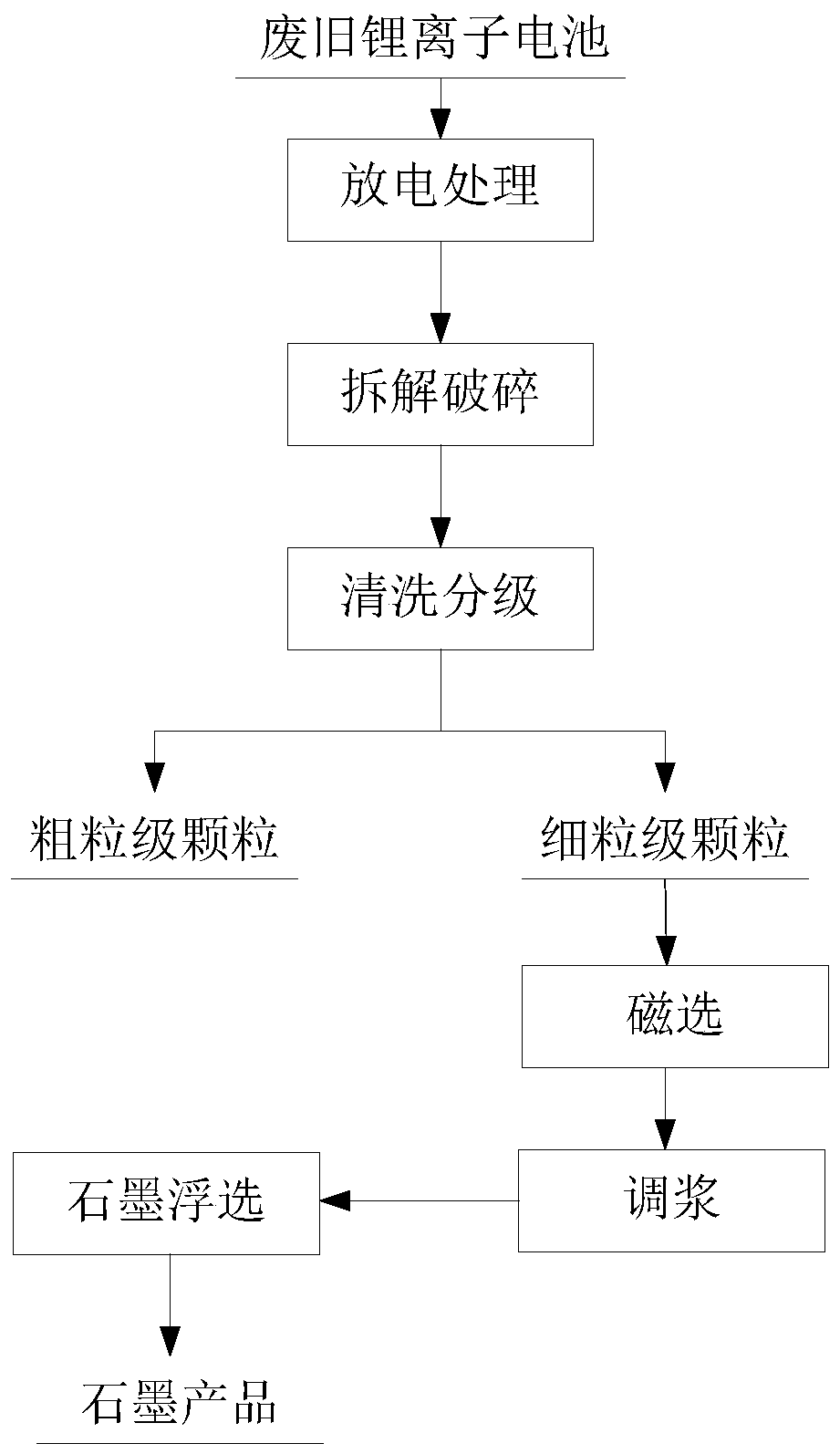

Image

Examples

Embodiment 1

[0041] Taking the waste lithium-ion battery of an enterprise in Shaanxi as the implementation object, it was crushed to less than 30mm after discharge, and then roasted at 600°C for 2 hours in a nitrogen protective atmosphere. After the pyrolysis material is cleaned, it is classified into two particle sizes of >0.15mm and <0.15mm. The <0.15mm particle size product is magnetically separated to remove impurities under a magnetic field strength of 240kA / m, and the magnetic separation tailings enter the flotation process. Adjust the magnetic separation tailings with water to a concentration of 20% pulp, and then add a composite regulator (being a mixture of sodium thioglycolate and water glass, the weight ratio of which is water glass: sodium thioglycolate = 1: 9), after stirring for 3 minutes, add kerosene at 180g / t, and finally add terpineol oil at 100g / t, stir for 2 minutes after the addition, the pH of the pulp reaches 7, and carry out graphite flotation for 6 minutes. Under t...

Embodiment 2

[0043] Taking the waste lithium-ion battery of an enterprise in Shaanxi as the implementation object, it was crushed to less than 30mm after discharge, and then roasted at 600°C for 2 hours in a nitrogen protective atmosphere. After the pyrolysis material is cleaned, it is classified into two particle sizes of >0.15mm and <0.15mm. The <0.15mm particle size product is magnetically separated to remove impurities under a magnetic field strength of 240kA / m, and the magnetic separation tailings enter the flotation process. Adjust the magnetic separation tailings with water to a concentration of 20% pulp, and then add a composite regulator (being a mixture of sodium thioglycolate and water glass, the weight ratio of which is water glass: sodium thioglycolate = 1: 20), after stirring for 3 minutes, add kerosene at 180g / t, and finally add terpineol oil at 100g / t, stir for 3 minutes after the addition, the pH of the pulp reaches 7, and carry out graphite flotation for 6 minutes. Under ...

Embodiment 3

[0045] Taking the waste lithium-ion battery of an enterprise in Shaanxi as the implementation object, it was crushed to less than 30mm after discharge, and then roasted at 600°C for 2 hours in a nitrogen protective atmosphere. After the pyrolysis material is cleaned, it is classified into two particle sizes of >0.15mm and <0.15mm. The <0.15mm particle size product is magnetically separated to remove impurities under a magnetic field strength of 240kA / m, and the magnetic separation tailings enter the flotation process. Adjust the magnetic separation tailings with water to a concentration of 20% pulp, and then add a composite regulator (being a mixture of sodium thioglycolate and water glass, the weight ratio of which is water glass: sodium thioglycolate = 1: 0.1), after stirring for 3 minutes, add kerosene at 180g / t, and finally add terpineol oil at 100g / t, stir for 3 minutes after the addition, the pH of the pulp reaches 7, and carry out graphite flotation for 6 minutes. Under...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap