Control method of washing machine and no-clean washing machine

A control method and washing machine technology, applied in the field of washing machines, can solve problems such as inability to clean, easy accumulation of dirt, and increased bacteria in washing machines, and achieve the effects of low vibration and noise, stable rotation, and reduced vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

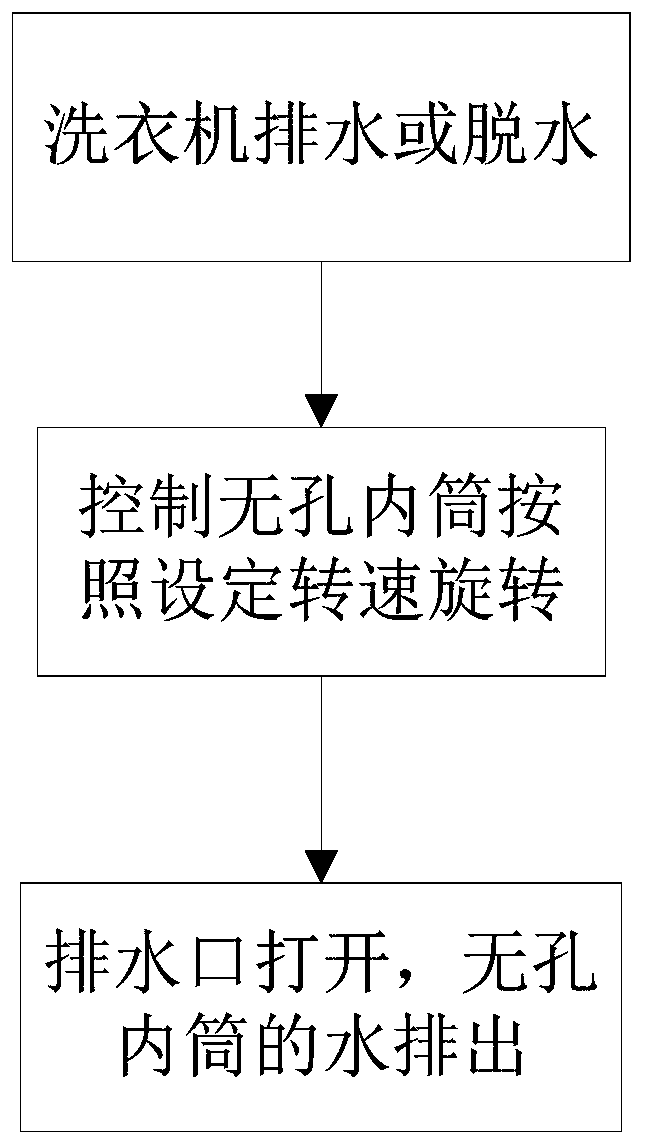

[0041] As an embodiment, when the washing machine performs dehydration, the non-porous inner tub 1 is controlled to rotate at a first set speed; when the washing machine performs water drainage, the non-porous inner tub 1 is controlled to rotate at a second set speed, and the first The set speed is greater than the second set speed.

[0042] As an embodiment, when the non-porous inner tube of the washing machine rotates at the first set speed, the valve core of the sealing valve is acted by centrifugal force to open the drain port 4 and make the water flow in the tube close to the wall; When the inner cylinder rotates at the second set speed, the centrifugal force and the closing force of the valve core of the sealing valve counteract to open the drain 4.

[0043] Preferably, the value range of the second set speed is 30-400 rpm, preferably 50-300 rpm, more preferably 90-200 rpm.

[0044] As an implementation manner, immediately before the washing machine performs water drainage or ...

Embodiment 1

[0057] Such as Figure 3-6 As shown, the present invention provides a method for controlling a washing machine.

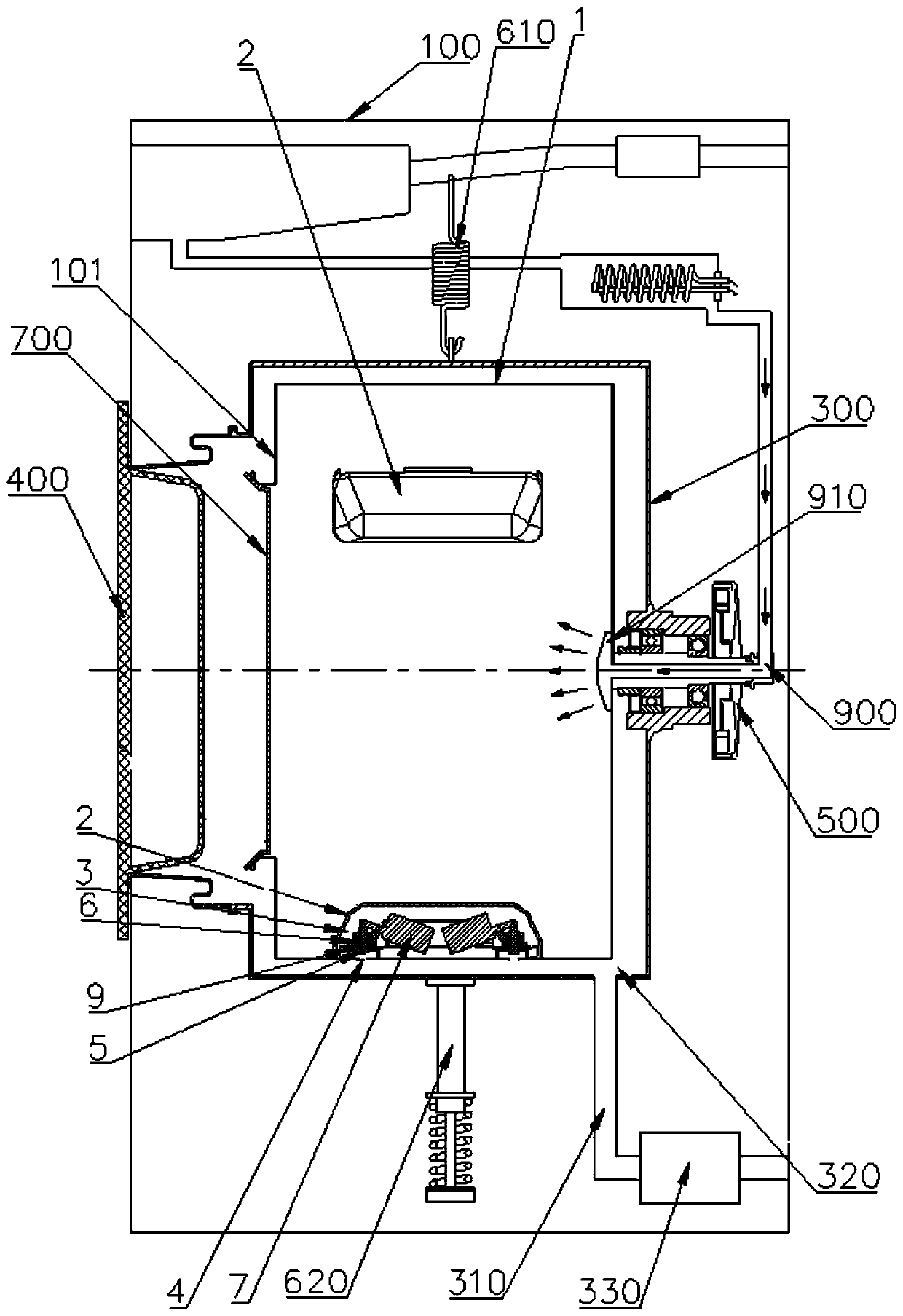

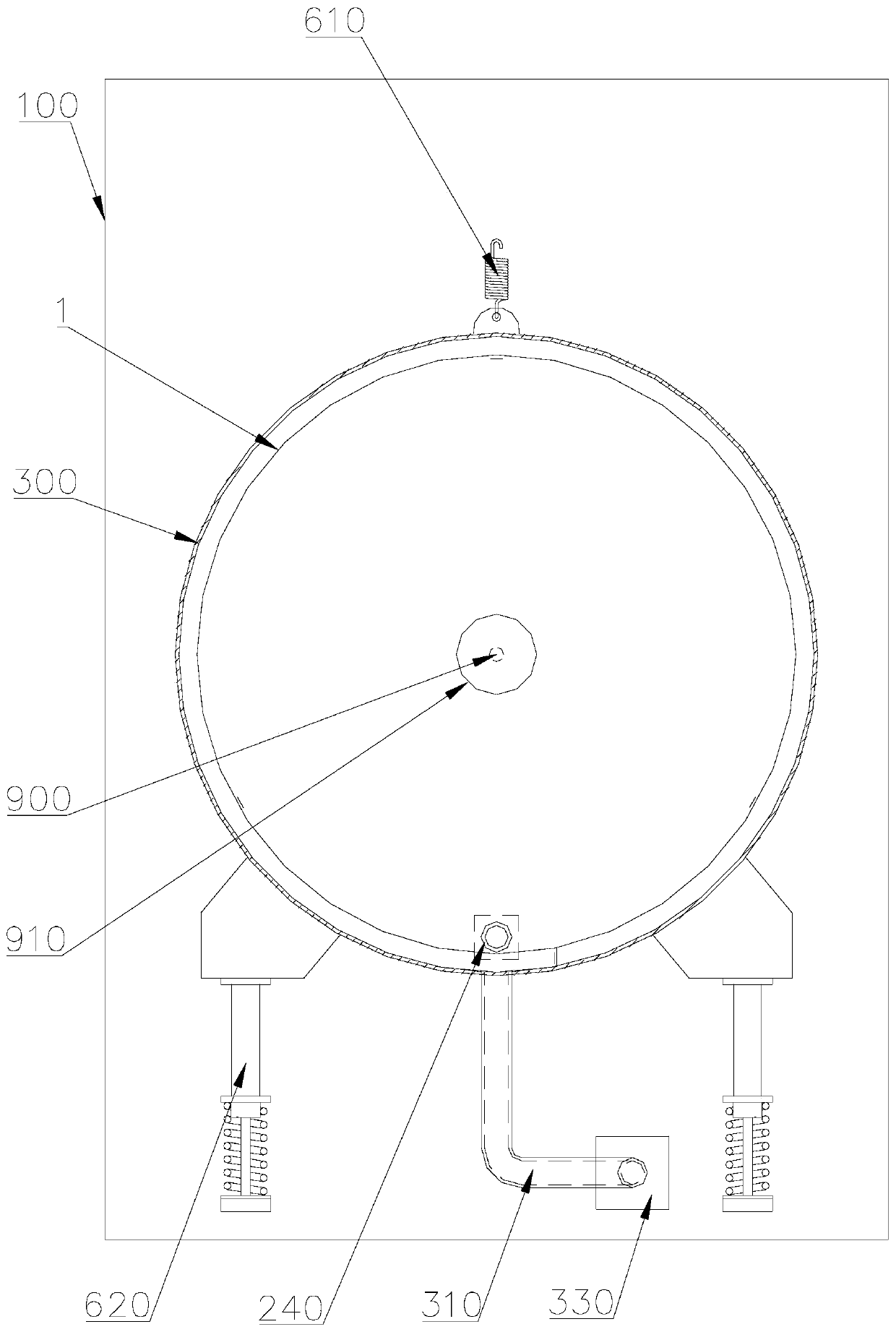

[0058] The washing machine reference figure 1 with figure 2 , Including the non-porous inner cylinder 1, the non-porous inner cylinder 1 is provided with a drain 4, and the drain 4 is provided with a sealing valve;

[0059] When the washing machine performs drainage or dehydration, the non-porous inner tub 1 is controlled to rotate at a corresponding set speed, so that the sealing valve opens the drain 4 by the centrifugal force of the inner tub rotation, and drains the water in the non-porous inner tub 1 .

[0060] The washing machine of the present invention is a drum washing machine, and the washing machine in this embodiment is a drum washing machine, which is controlled by controlling the rotation speed of the non-porous inner tub 1.

[0061] When the washing machine performs dehydration, the non-porous inner tub 1 is controlled to rotate at a first set speed; when ...

Embodiment 2

[0083] This embodiment relates to a specific structure of the washing machine according to the present invention.

[0084] The washing machine includes a housing 100 in which a non-porous inner tub 1 is provided. The axis of the non-porous inner tub 1 extends horizontally or is gradually inclined downward from front to back. The front end of the non-porous inner tub 1 is an inner tub mouth 101 with an opening. , The rear end is the bottom of the inner cylinder with a seal.

[0085] The wall of the non-porous inner cylinder 1 is not provided with a through hole, so that the inside of the non-porous inner cylinder 1 constitutes a sealed container with only the front opening. At the same time, a door cover 400 that can be opened outwards is installed at the front end of the washing machine housing 100 to close the inner tube opening 101 after the door cover 400 is closed. After opening the door cover 400, clothes are placed into the non-porous inner tube 1 from the inner tube opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com