Hand-operated long sleeper mounting machine capable of being automatically locked and long sleeper mounting method

A kind of installation machine and hand-operated technology, applied in the direction of clockwork mechanism, portable lifting device, track, etc., can solve the problems of sleeper displacement, manual lifting of sleeper instability, low efficiency of sleeper installation, etc., to reduce construction errors , Accelerate the speed of track laying and reduce the effect of staffing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

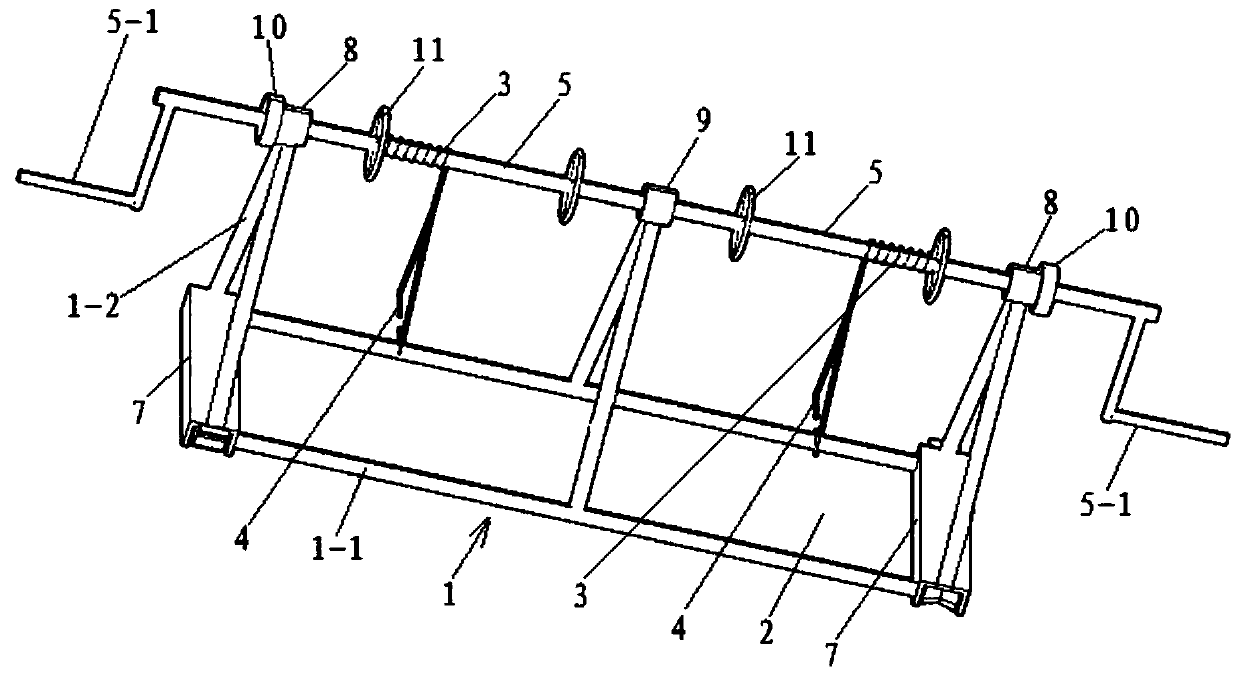

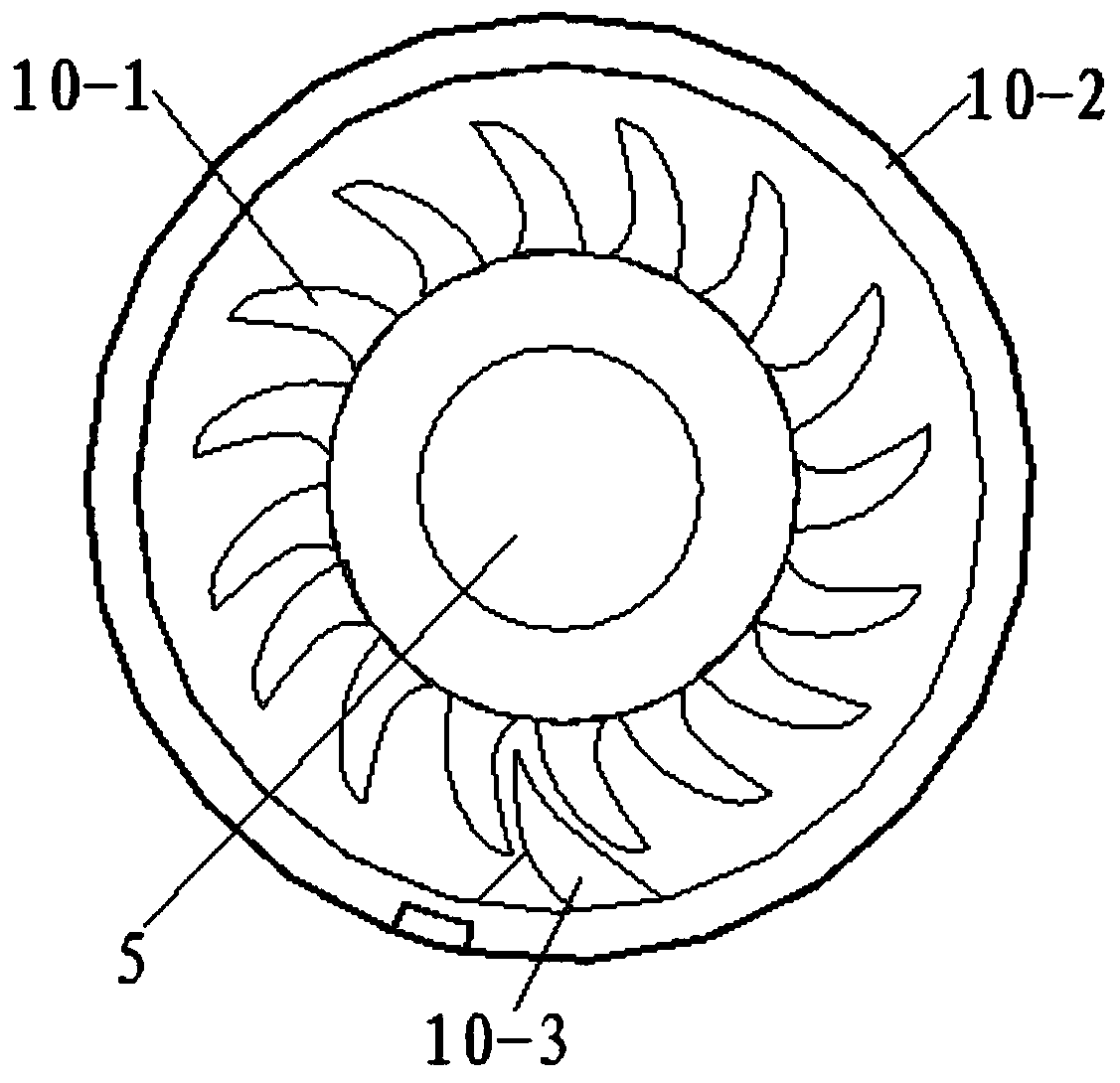

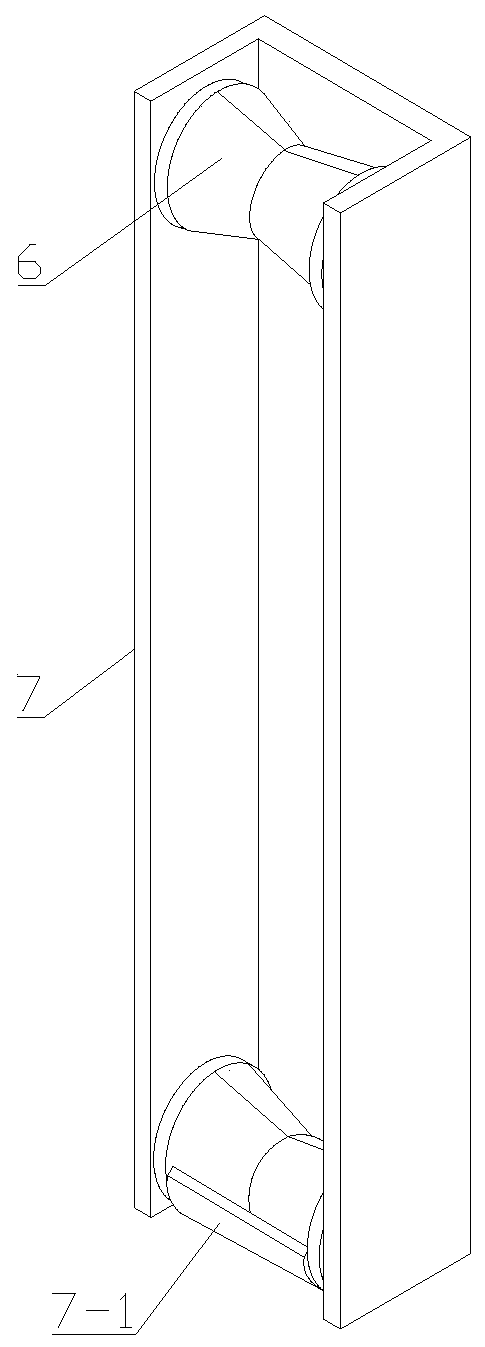

[0050] Such as Figure 1 to Figure 3 A hand-operated long sleeper installation machine that can be automatically locked as shown includes a frame 1 installed on the track and two sleeper lifting units symmetrically installed on the frame 1. The two sleeper lifting units of the frame 1 The lower part of the side is respectively provided with a lockable guide roller mechanism, the guide roller mechanism is matched with the rail of the track, the sleeper lifting unit includes a winding mechanism and a sleeper hook 4, and the sleeper hook 4 passes through the suspension wire 3 is suspended below the wire winding mechanism, the wire winding mechanism includes a rotating shaft 5 that is rotatably installed on one side of the frame 1 and is used for winding the suspension wire 3, and two sides of the frame 1 are respectively provided with one for driving The hand crank 5-1 that the rotating shaft 5 rotates, the upper end of the suspension wire 3 is wound on the rotating shaft 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com