Method for determining performance of desulfurization and denitrification activated carbon and application thereof

A technology of desulfurization, denitrification and activated carbon, which is applied in chemical method analysis, measuring devices, instruments, etc., can solve the problems of judging analysis tower analysis, water capacity error, complexity, etc., and achieves the effect of short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

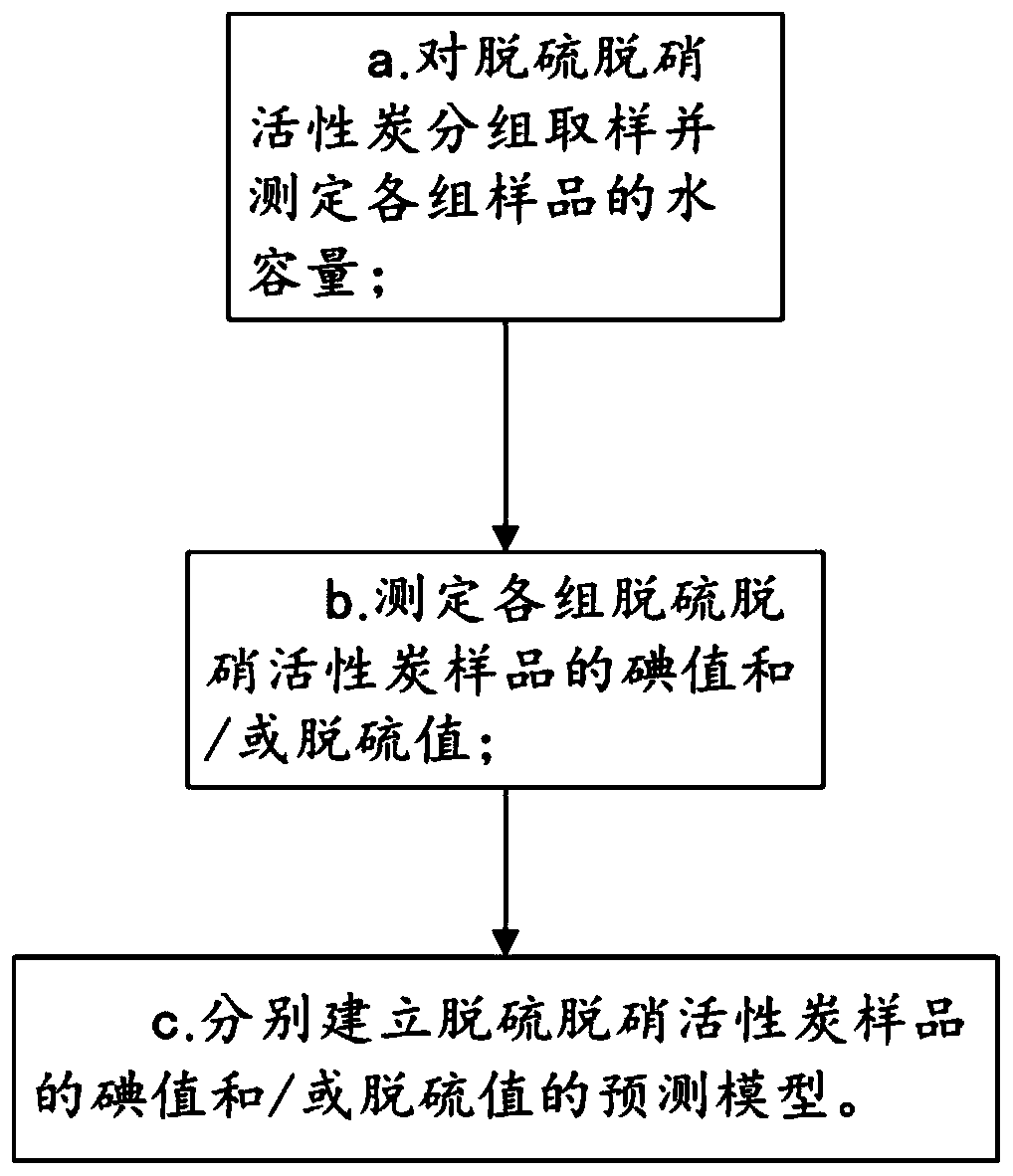

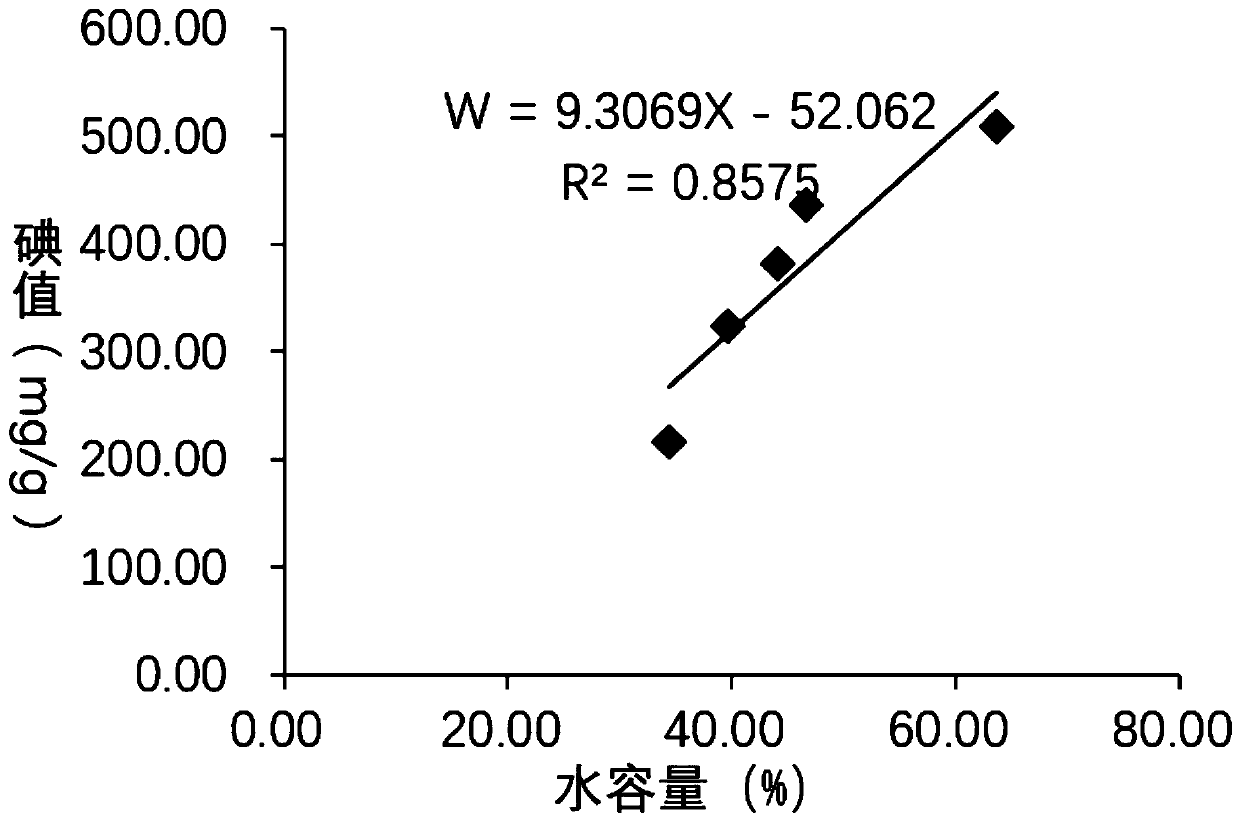

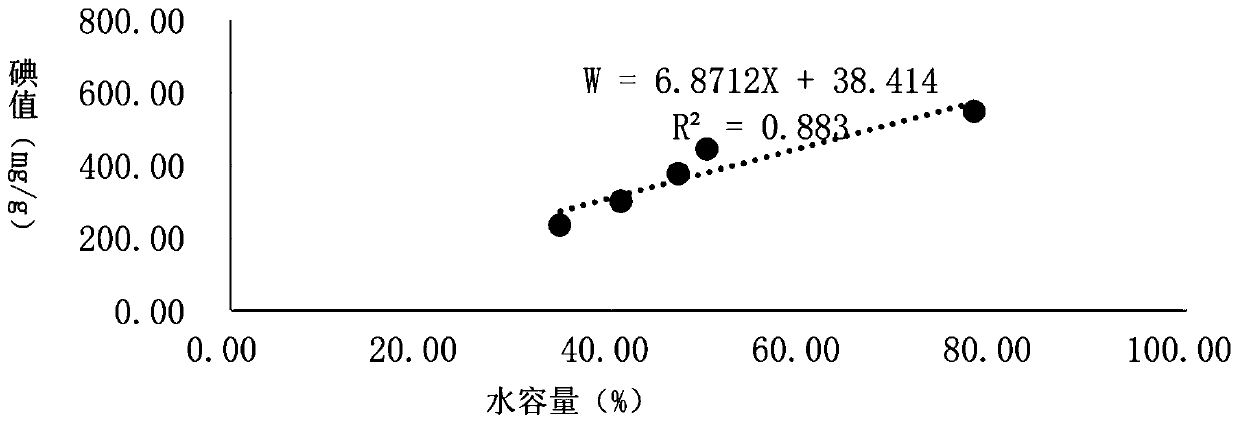

[0092] Example 1: Prediction of iodine value of desulfurization and denitrification activated carbon performance index

[0093] Sampling is taken from Table 1, and five groups of samples are taken for each parallel experiment, all adopting the existing conventional measurement methods in the industry (for example, using GB / T 7702.5-1997 to measure water capacity, using GB / T

[0094] 7702.7-87 measure iodine value), measure the water capacity and iodine value of these samples, as shown in table 2 and table 3, so that follow-up drawing scatter diagram:

[0095] Table 2 The iodine value and water capacity values of five groups of samples in the first group of parallel experiments

[0096] Sample serial number 1# 2# 3# 4# 5# Iodine value (mg / g) 216.00 324.00 381.00 435.00 509.00 Water capacity (%) 34.36 39.72 44.03 46.62 63.63

[0097] Table 3 The iodine value and water capacity values of the five groups of samples in the second group of...

Embodiment 2

[0112] Example 2: Prediction of desulfurization value of desulfurization and denitrification activated carbon performance index

[0113] A prediction model for water capacity value X and desulfurization value Y can then be established. The specific method is to take samples from Table 1, and each parallel experiment takes five groups of samples, all using the existing conventional measurement methods in the industry (for example, using GB / T 7702.5-1997 to measure water capacity, using GB / T 30202.4-2013 to measure Desulfurization value), measure the water capacity and desulfurization value of these samples, as shown in Table 7 and Table 8, so that follow-up drawing scatter diagram:

[0114] Table 7 The desulfurization value, water capacity and iodine value of the five groups of samples in the first group of parallel experiments

[0115] Sample serial number 1# 2# 3# 4# 5# Iodine value (mg / g) 216.00 324.00 381.00 435.00 509.00 Desulfurization value...

Embodiment 3

[0129] Example 3: Prediction of denitrification rate of desulfurization and denitrification activated carbon performance indicators

[0130] The above method establishes and selects the optimal prediction model of water capacity, iodine value and desulfurization value. In addition, the present invention also establishes a prediction model of water capacity and denitrification rate. The specific method is, first select three groups of desulfurization and denitrification activated carbon samples with different iodine values from Table 1 (see Table 12 and Table 13):

[0131] Table 12 The first group of parallel experiments three groups of different iodine value samples

[0132] Sample serial number 15# 16# 17# Iodine value (mg / g) 200-250 350-400 >500

[0133] Table 13 The second group of parallel experiments three groups of different iodine value samples

[0134] Sample serial number 18# 19# 20# Iodine value (mg / g) 200-250 350-400 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com