Metal grid structure, touch screen and touch display screen

A metal grid, touch screen technology, applied in the field of touch screen and touch display screen, metal grid structure, can solve the problems of metal lead production process capacity limitation, poor, increased touch driver IC design, etc. To achieve the effect of narrow border effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to illustrate the touch screen provided by the present invention and the manufacturing method thereof, a detailed description will be given below in conjunction with the accompanying drawings and the written description of the embodiments.

[0032] The invention provides a metal grid structure and a touch screen adopting the metal grid structure.

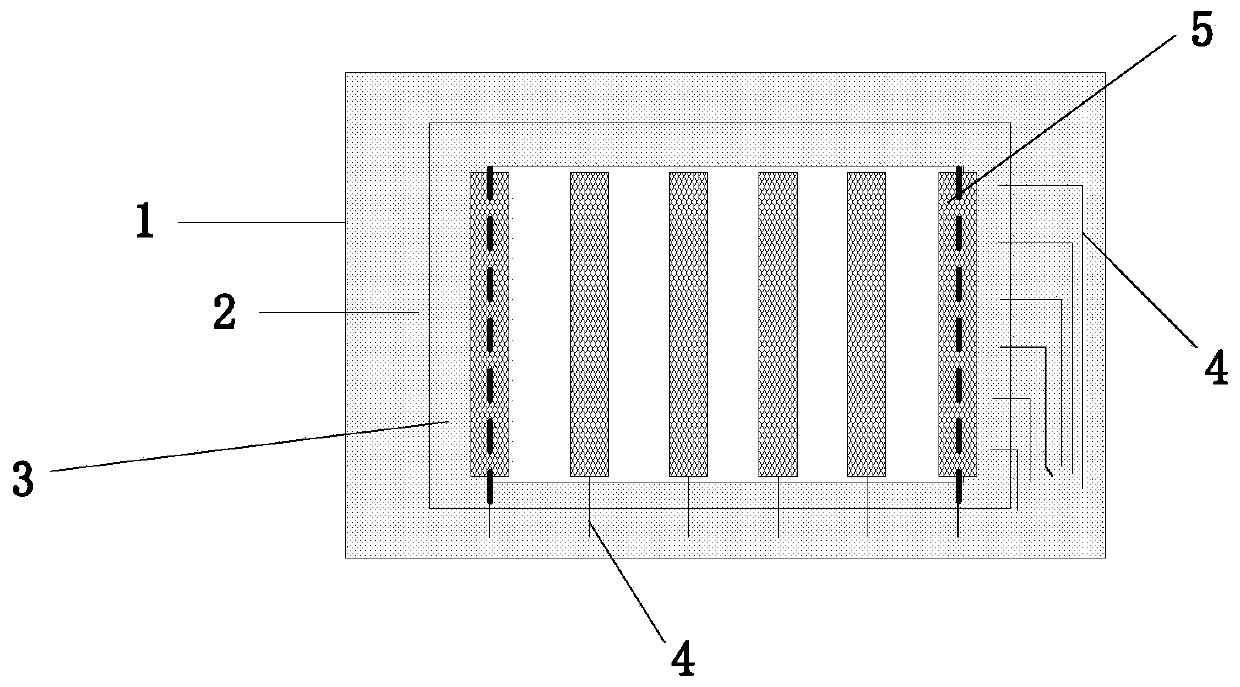

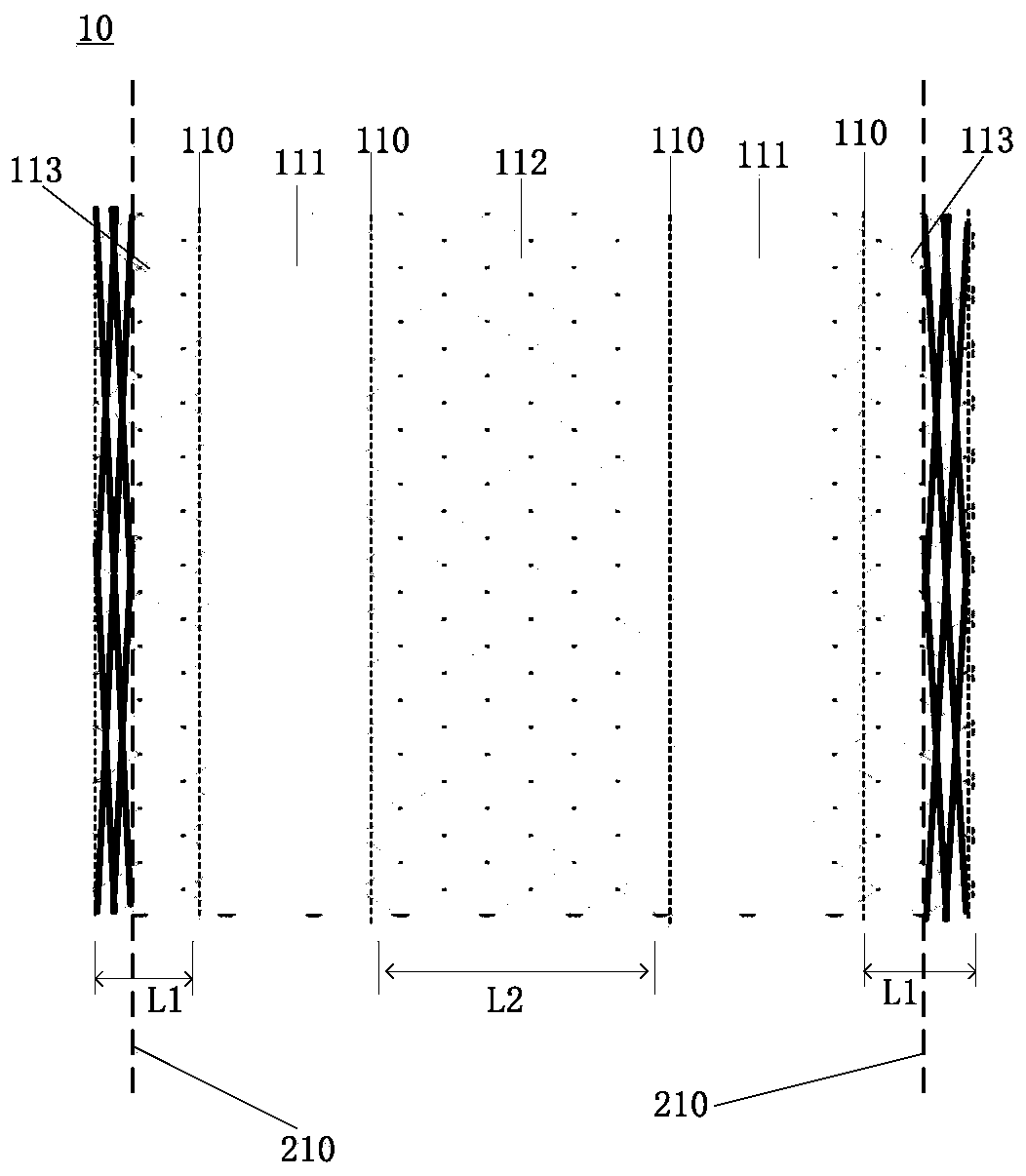

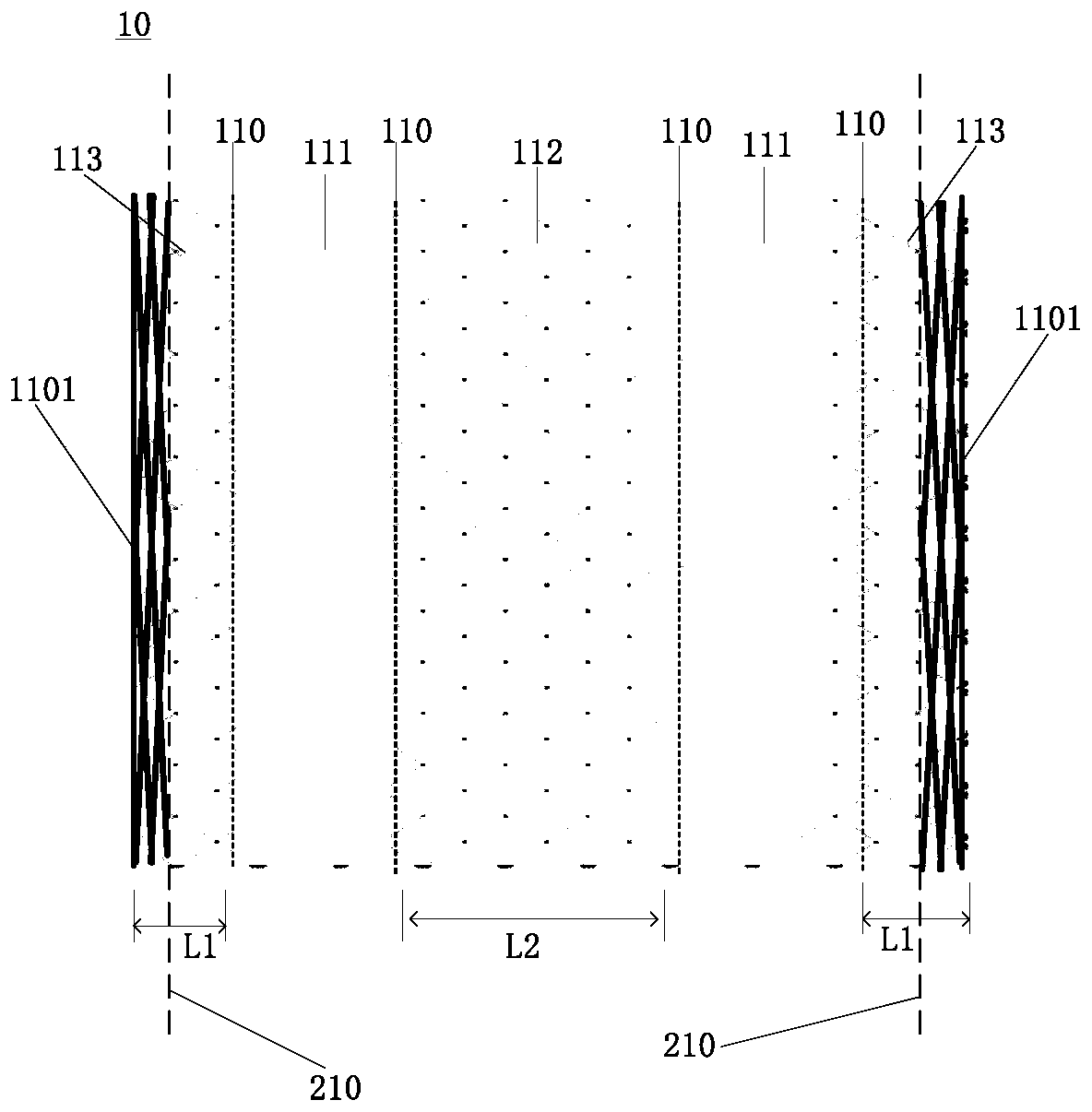

[0033] In a specific embodiment, the metal grid structure can be designed as a first metal grid structure 10 or a second metal grid structure 20 . A touch screen is formed by stacking the first metal grid structure 10 and the second metal grid structure 20 .

[0034] Such as figure 2 As shown, the first metal grid structure 10 provided by the embodiment of the present invention includes: metal grid lines formed by crossing metal wires, and the metal grid lines are separated by break lines 110 to form a spacer The first touch electrode channel of the row and the first Dummy block 111, the first touch electrode chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com