Liquid crystal display assembly, liquid crystal display device and manufacturing method of liquid crystal display assembly

A technology of liquid crystal display and components, which is applied in the direction of instruments, nonlinear optics, optics, etc., and can solve problems such as the inability to narrow the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

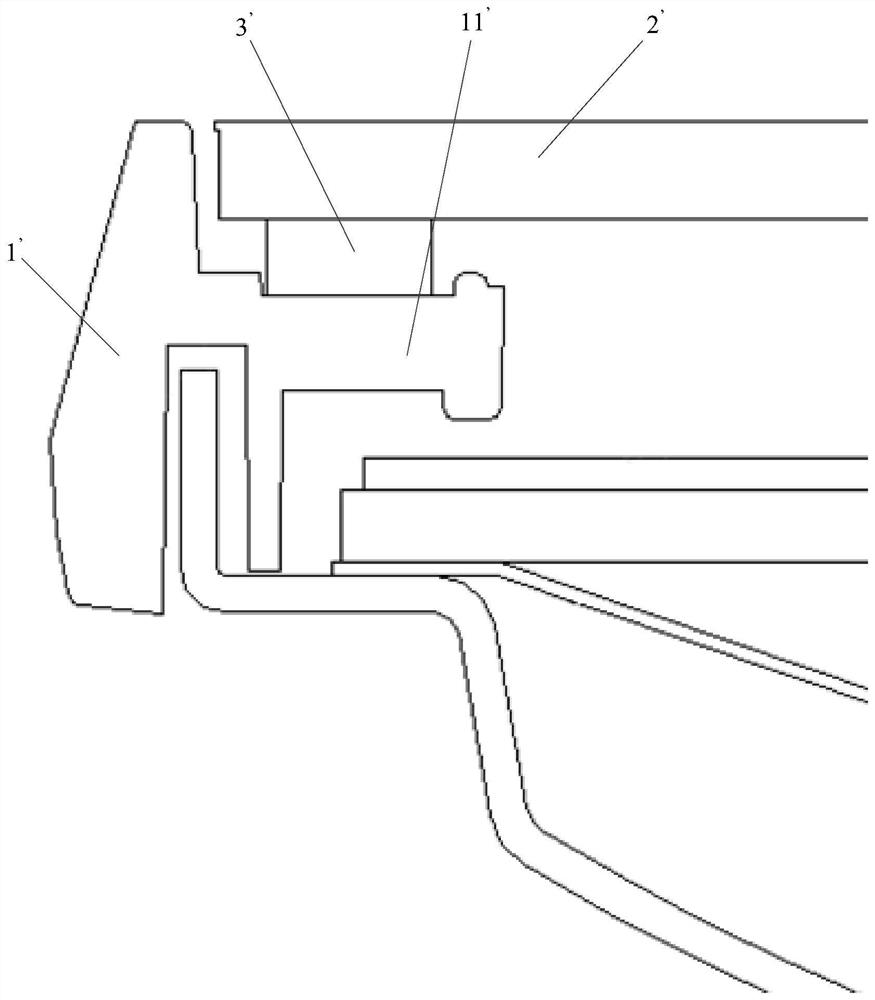

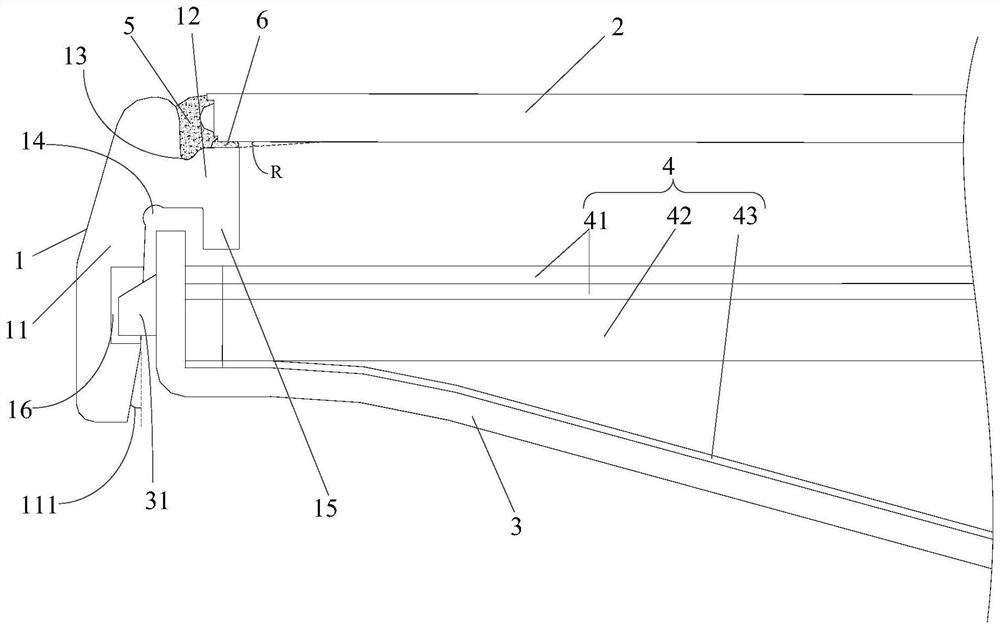

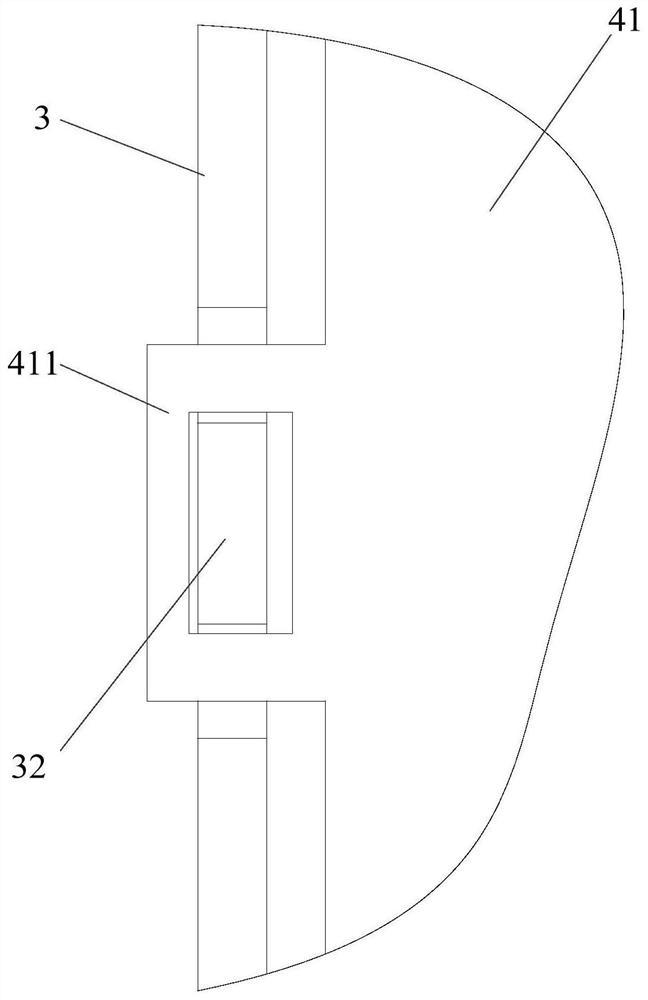

[0052] Such as figure 2 As shown, a liquid crystal display assembly proposed in Embodiment 1 of the present invention includes: a support frame 1, a liquid crystal panel 2, a backplane 3, and a backlight assembly 4; the support frame 1 includes a frame main body 11 and a support table 12, The first end of the frame body 11 surrounds the back plate 3 and is connected to the back plate 3 , and the second end of the frame body 11 extends toward the middle of the support frame 1 to form the support platform 12 , the liquid crystal panel 2 rides on the support surface of the support platform 12, a colloid layer 6 is arranged between the support surface of the support platform 12 and the liquid crystal panel 2, and the liquid crystal panel 2 and the back plate 3 to form an accommodating space, the backlight assembly 4 is arranged in the accommodating space and connected with the back panel 3 .

[0053] Specifically, it can be understood that in order to enable the liquid crystal d...

Embodiment 2

[0075] Embodiment 2 of the present invention proposes a liquid crystal display device, which includes: figure 2 The liquid crystal display assembly shown; the liquid crystal display assembly includes: a support frame 1, a liquid crystal panel 2, a back plate 3, and a backlight assembly 4; the support frame 1 includes a frame main body 11 and a support platform 12, and the first frame main body 11 One end surrounds the back plate 3 and is connected to the back plate 3, the second end of the frame body 11 extends to the middle of the support frame 1 to form the support platform 12, and the liquid crystal panel 2 is built on On the support surface of the support platform 12, a colloid layer 6 is arranged between the support surface of the support platform 12 and the liquid crystal panel 2, and an accommodating space is formed between the liquid crystal panel 2 and the back plate 3 , the backlight assembly 4 is arranged in the accommodating space and connected with the backplane ...

Embodiment 3

[0079] Embodiment 3 of the present invention proposes a method for manufacturing a liquid crystal display component, which is used to manufacture the liquid crystal display component proposed in Embodiment 1 above, which includes: Figure 6 as shown,

[0080] 301. Use a mold to position the support frame, and perform the first dispensing of glue on the support platform at the first end of the support frame.

[0081] Specifically, the mold used for positioning the support frame by the mold 7 is set by the technician according to the specific structure of the support frame, such as Figure 7 The mold shown can be divided into two parts, the first part mold 71 is used to be placed in the space surrounded by the support frame, the middle space surrounded by the support frame is positioned, and it is against the extension end of the support platform of the support frame Top, the second part of the mold 72 is used to extrude the outside of the support frame and press it against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com