Multifunctional high-voltage cable hoisting and laying guide arm and laying method thereof

A high-voltage cable and guide arm technology, which is applied in the direction of cable laying equipment, cable installation, cable installation device, etc., can solve the problems of low construction efficiency and aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

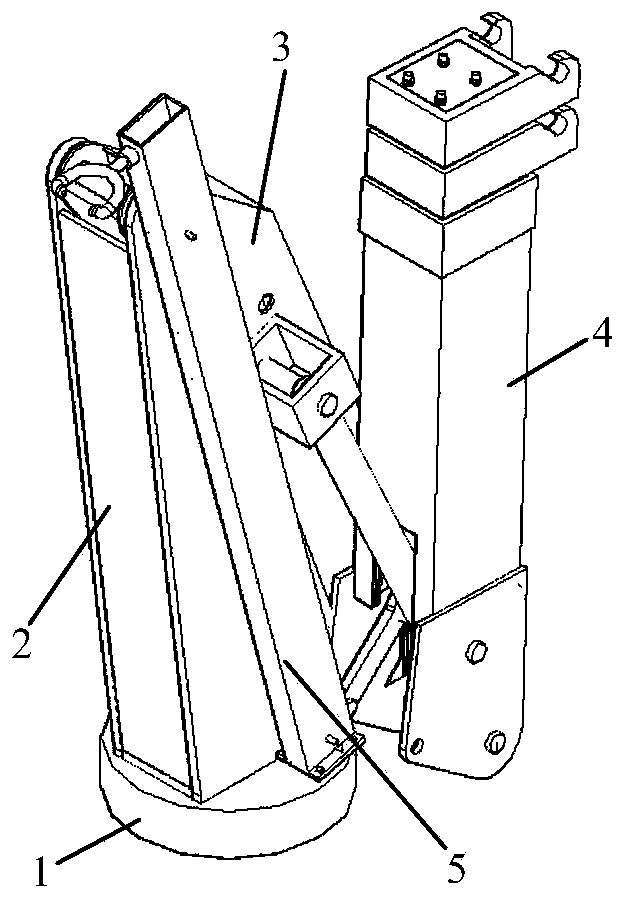

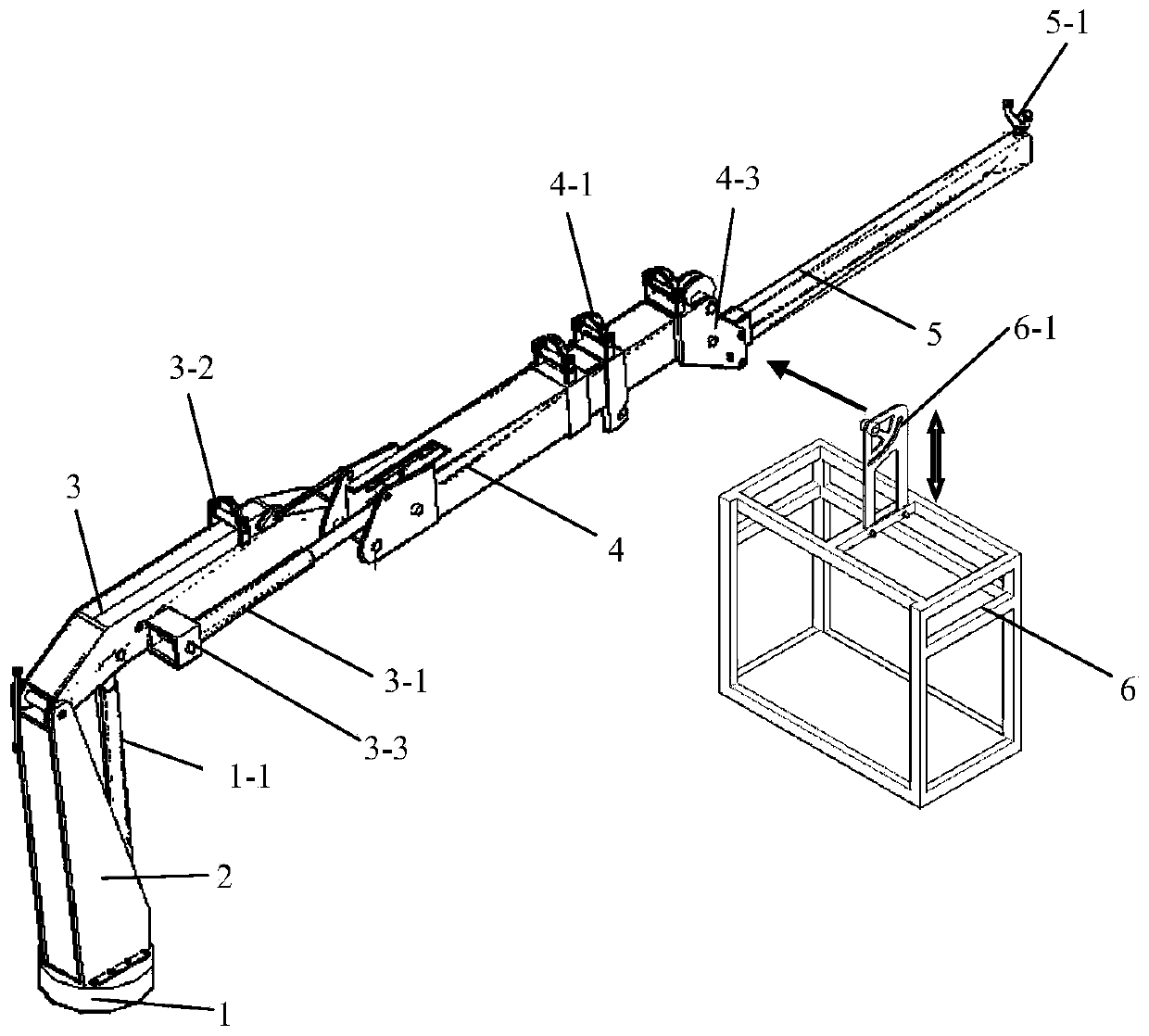

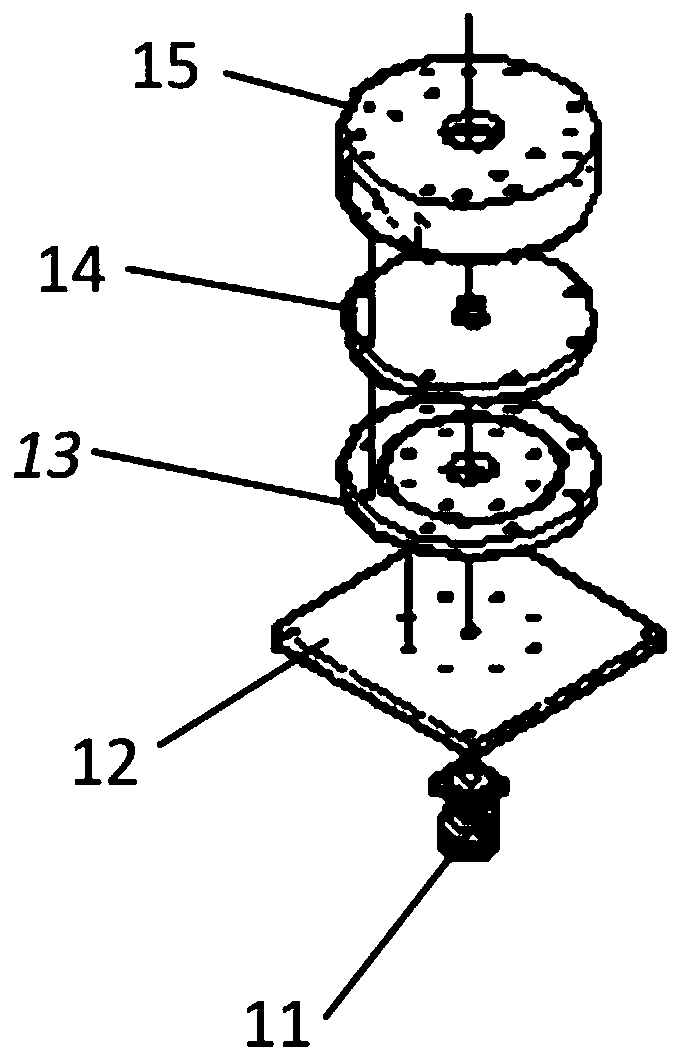

[0024] Please refer to Figure 1-Figure 2 , a multi-functional guide arm for lifting and laying high-voltage cables, including a rotator assembly 1 providing rotation, a column assembly 2 providing support, a folding arm assembly 3, a multi-stage telescopic arm assembly 4, an auxiliary extension arm 5, and an operation Hanging basket assembly 6 and control device for personnel working at height; the lower part of the revolving body assembly is fixed on the external movable car body, the upper end is fixed on the lower end of the column assembly 2, and the two ends of the folding arm assembly 3 are respectively connected to the fixed column assembly 2 and The multi-stage telescopic arm assembly 4 is hinged, and a folding control cylinder 1-1 is provided between the folding arm assembly 3 and the rotary body assembly 1 or the column assembly 2. One side of the folding arm ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com