Lollipop discharging device

A technology for lollipops and driving devices, which is applied in confectionery, confectionery industry, food science and other directions, can solve the problems of low efficiency and quality of unloading, complicated process of inserting sticks, and low quality of inserting sticks, etc. The effect of being too complicated, reducing operating procedures and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

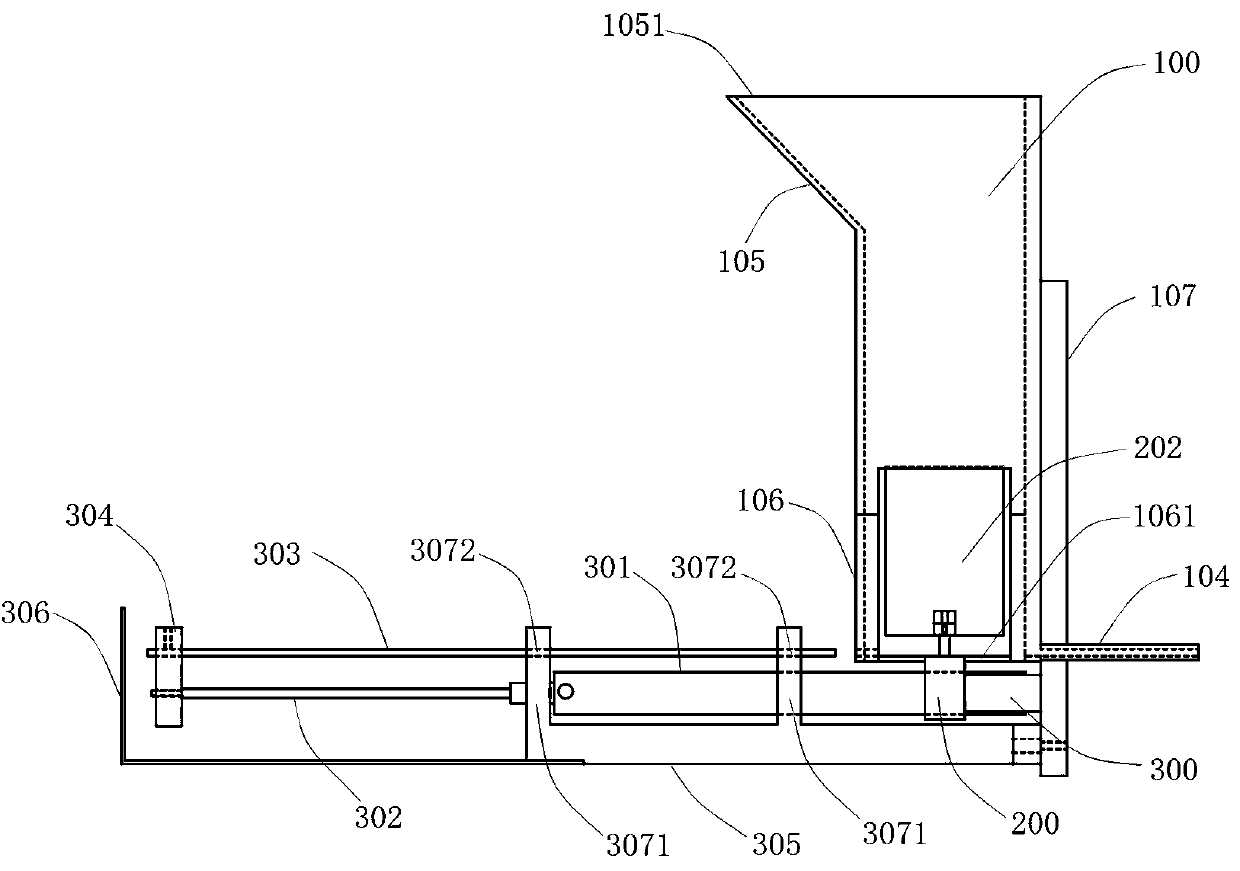

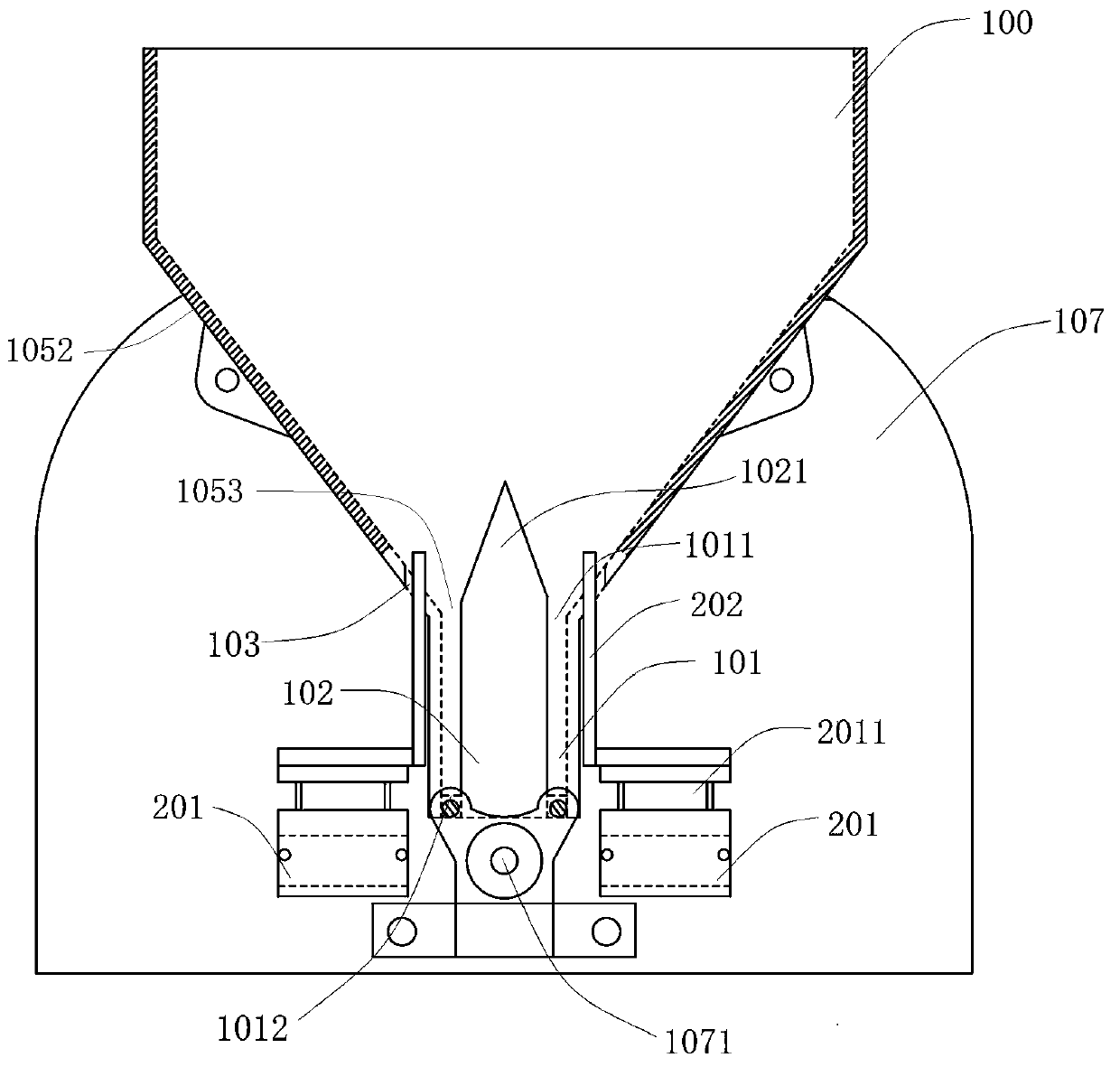

[0035] Such as Figure 1-2 , The lollipop unloading device includes a hopper 100 , a splitter assembly 102 , a drive assembly 202 , a separation drive device 200 , a stick outlet channel 104 , and a stick feeding mechanism 300 .

[0036] Wherein, the hopper 100 is provided with a feeding part 105 and a base part 106. The feeding part 105 is installed on the top of the base part 106, and has a feeding inclined surface inclined outwards from the tops of both sides of the base part 106. Inside the base part 106 The feeding inclined surface has at least one feeding channel 101 . The hopper 100 has a hopper inlet 1051 and a hopper outlet 1061 , the hopper inlet 1051 is formed at the top of the feeding part 105 , and the hopper outlet 1061 is formed at the bottom of the base part 106 . The feed channel 101 has a feed channel inlet 1011 and a feed channel outlet 1012. The feed channel 101 extends from the middle of the hopper 100 to the hopper outlet 1061. The feed channel outlet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com