Down filling device and method for down jacket

A technology of down jackets and down, which is applied in the direction of sewing tools, etc., can solve the problems of down jacket quality reduction, uneven distribution of down, and low quality of down jackets, and achieve the effects of improving the appearance and quality, reducing the breakage rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

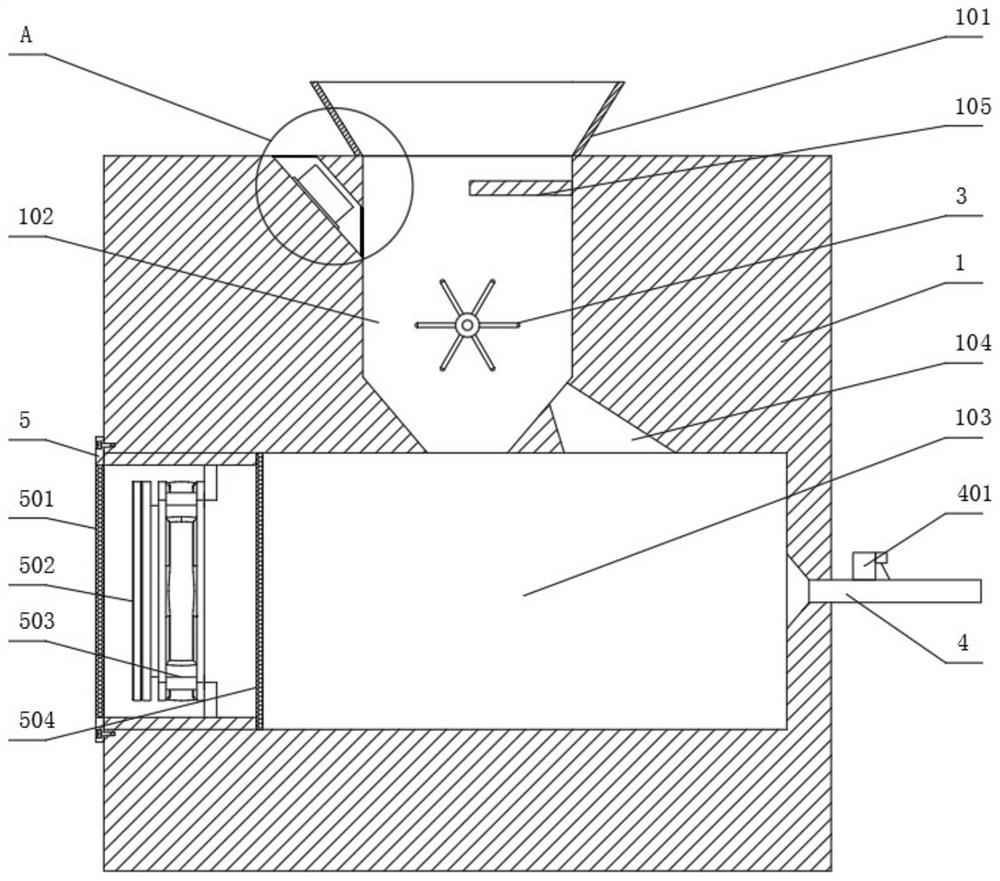

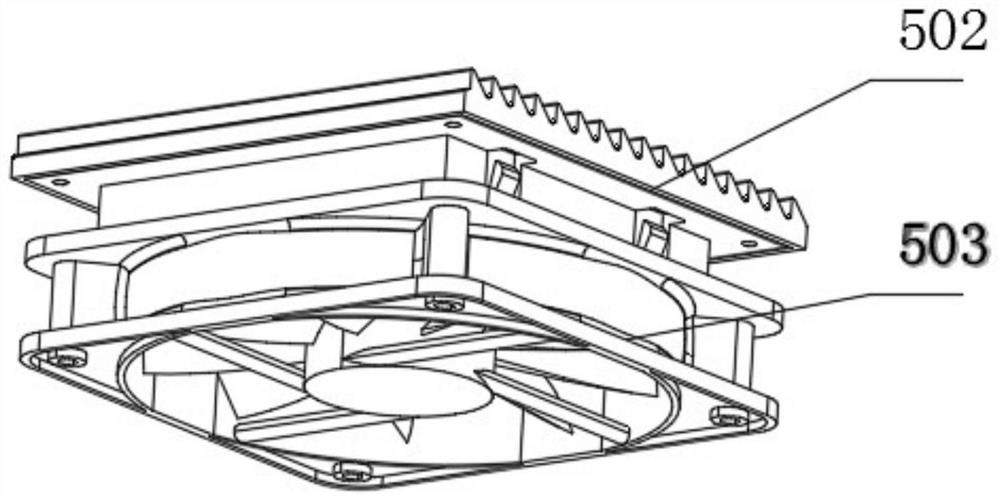

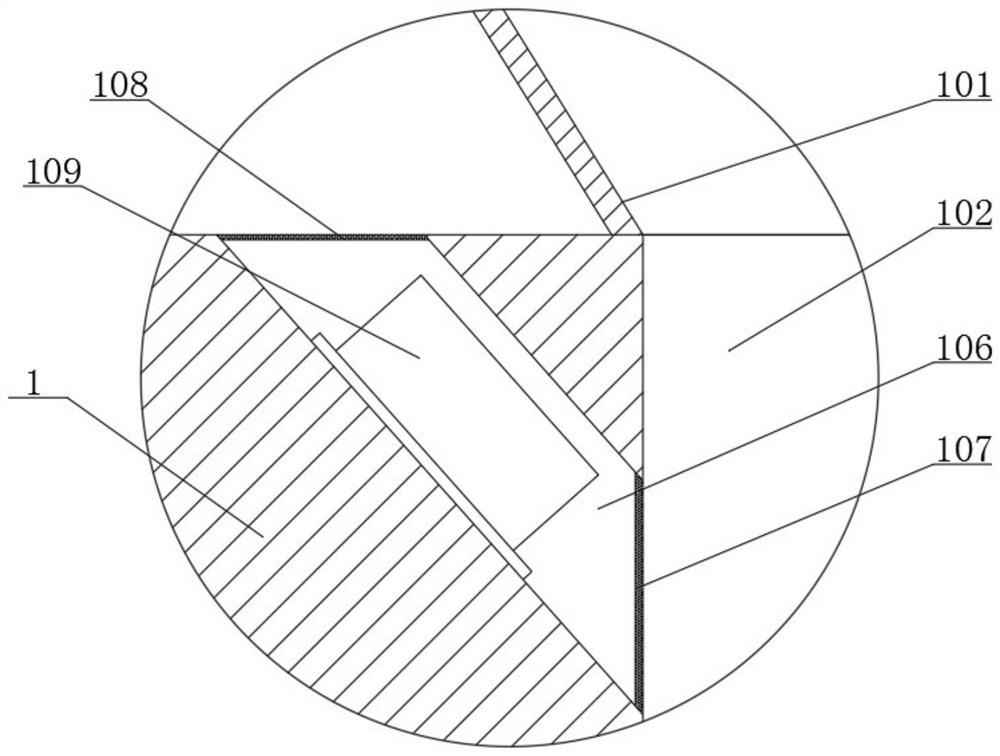

[0028] like Figure 1-3 As shown, a down filling device and method for down clothing, wherein the device includes a device main body 1, a material inlet 101, a filling chamber 103, a down filling port 4 and a valve 401 located on the down filling port 4, the material inlet 101 and the down filling port 4 A feeding chute 102 is provided between the filling chambers 103, and a mounting groove 106 is provided on one side of the inner wall of the feeding chute 102, and a backflow groove 104 is provided on the other side of the inner wall of the feeding chute 102. Inside the mounting groove 106 The first blower fan 109 is installed, and the installation groove 106 runs through the main body 1 of the device. The feeding tank 102 communicates with the filling chamber 103 through the return tank 104. The diffuser 3 is detachably connected with an air supply mechanism in the filling chamber 103;

[0029] like figure 1 and image 3 As shown, the first filter screen 107 is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com