Fire hose cleaning device

A technology for cleaning devices and fire hoses, applied to cleaning methods and tools, cleaning methods using tools, cleaning methods using liquids, etc., can solve problems such as loose fire hoses and poor cleaning effects of fire hoses, and achieve The effect of preventing wear, increasing the force bearing area, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

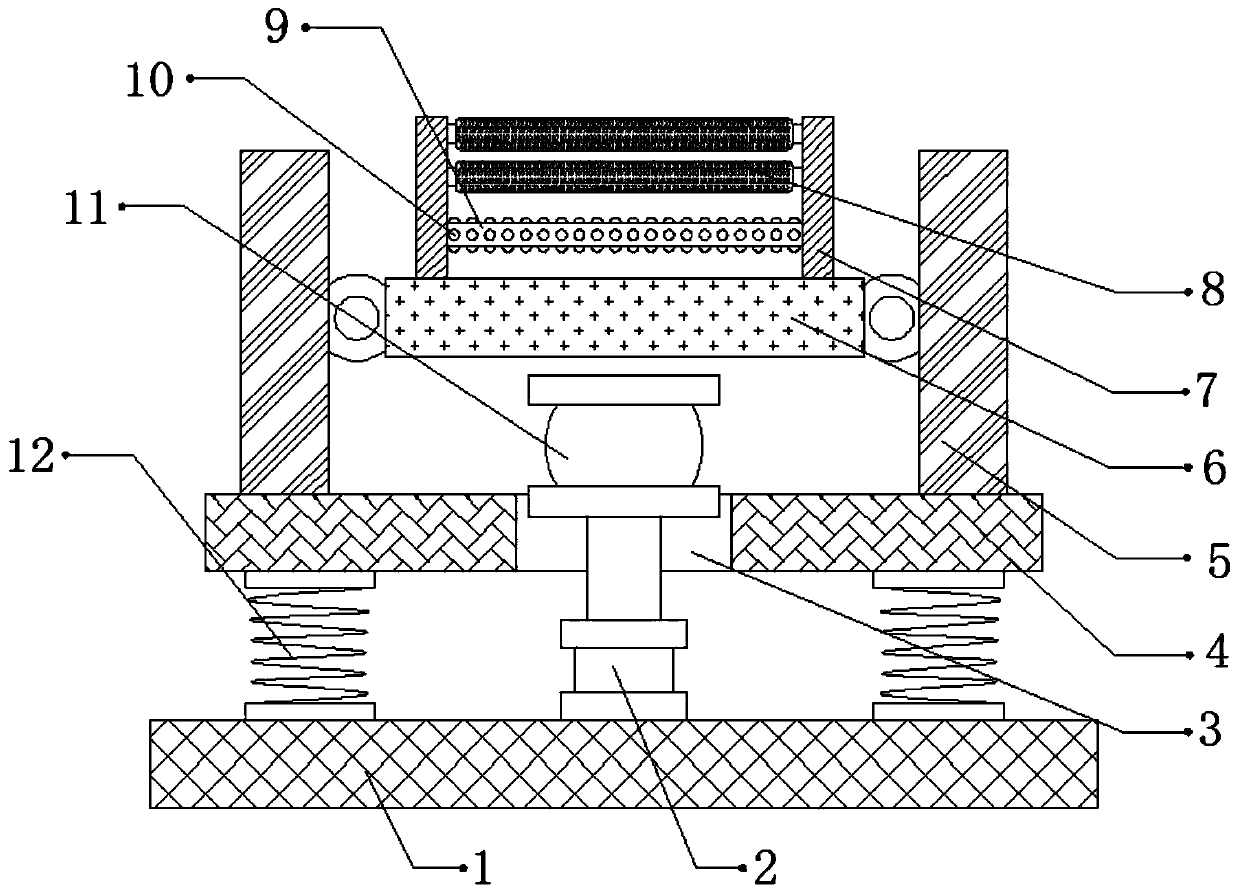

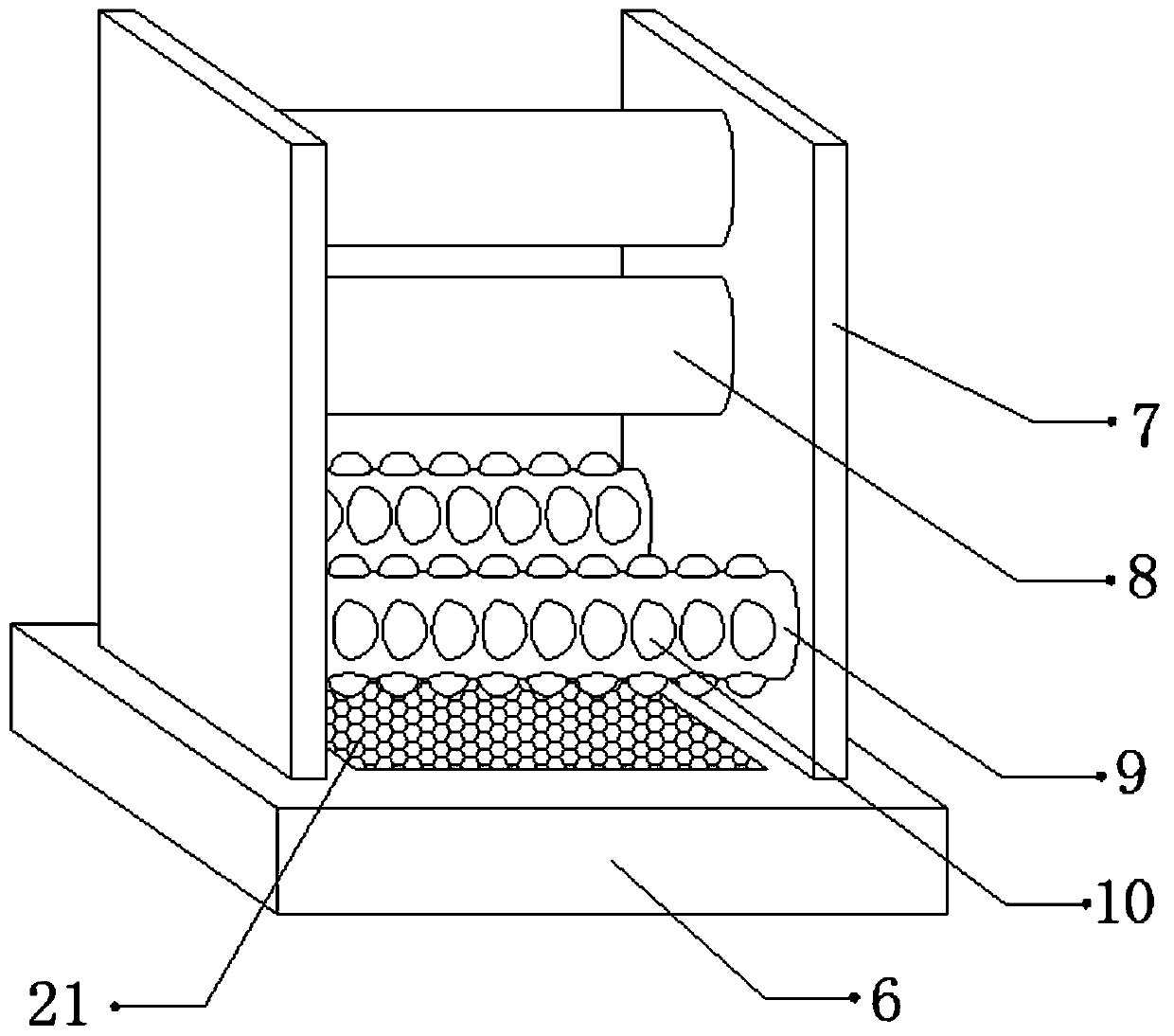

[0029] refer to Figure 1-3 , a fire hose cleaning device, comprising a fixed seat 1, one side of the top outer wall of the fixed seat 1 is connected with a cleaning box 13 by bolts, and the top outer wall of the fixed seat 1 is connected with two springs 12 by bolts, and the two springs 12 The top outer walls of the top are all connected with fixed plates 4 by bolts, the two sides of the top outer walls of the fixed plates 4 are connected with connecting plates 5 by bolts, and the opposite side outer walls of the two connecting plates 5 are connected with support plates 6 by hinges , both sides of the top outer wall of the support plate 6 are connected with fixed blocks 7 by bolts, and two support rods 9 are connected by bolts between the outer walls of the opposite side of the two fixed blocks 7, and the outer walls of the two support rods 9 are A ball groove is provided, and the inner wall of the ball groove is rollingly connected with balls 10, and the outer walls of the o...

Embodiment 2

[0039] refer to Figure 4 , a fire hose cleaning device. Compared with Embodiment 1, the top outer wall of the support plate 6 is connected with a diverter plate 22 by bolts, and the outer walls on both sides of the diverter plate 22 are provided with a plurality of diversion grooves 23 .

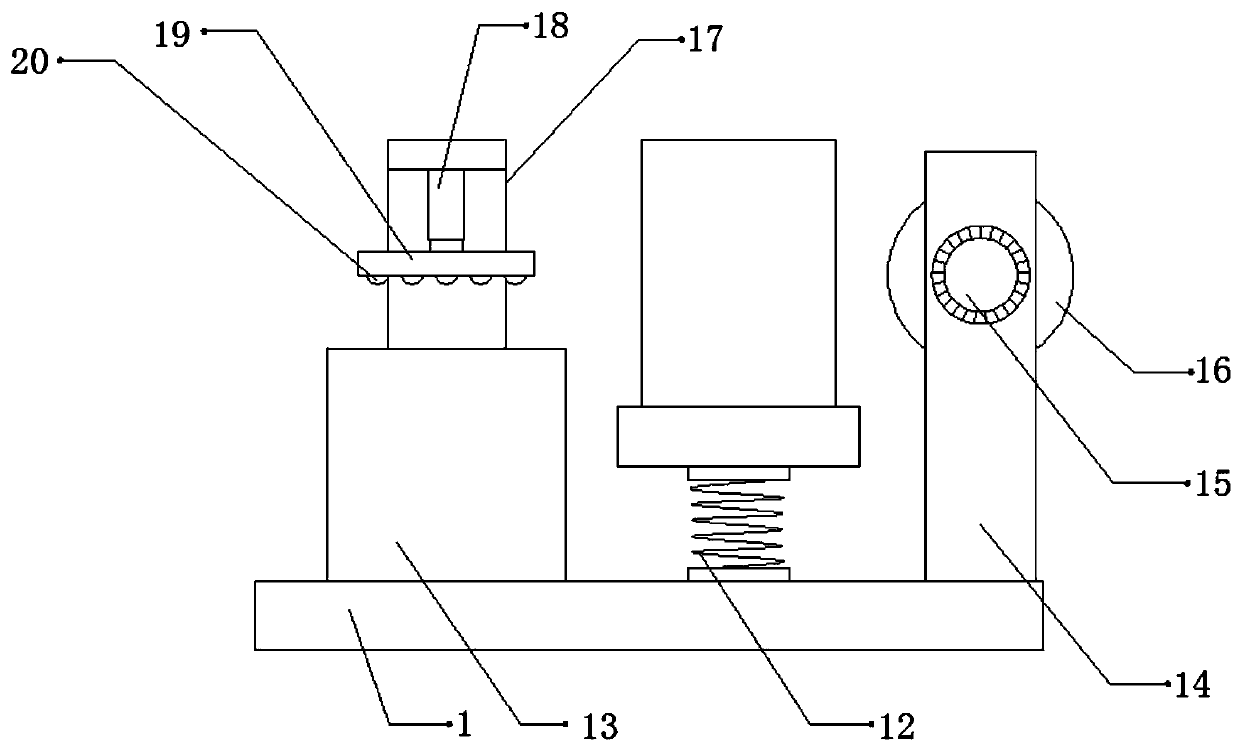

[0040] Working principle: When in use, one end of the fire hose that needs to be cleaned is wound on the surface of the winding roller 16 through the cleaning box 13, the support rod 9, the cleaning roller 8 and the support rod 9, and the motor 15 is started, and the motor 15 will drive the fire fighting machine. During the winding of the hose, the hydraulic rod 18 is activated, and the hydraulic rod 18 will drive the pressure plate 19 to move downward, so that the fire hose is immersed in the cleaning box 13 through the pressure plate 19, so as to effectively clean the fire hose , to prevent the fire hose from floating on the water surface due to the large buoyancy, which will affect the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com