Flattening mechanism used for granary grains

A grain and granary technology, applied in the field of storage equipment, can solve the problems of frequent movement, excessive accumulation of grain heat, inconvenient storage management and measurement, and achieve the effect of increasing the area and reducing the area occupied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

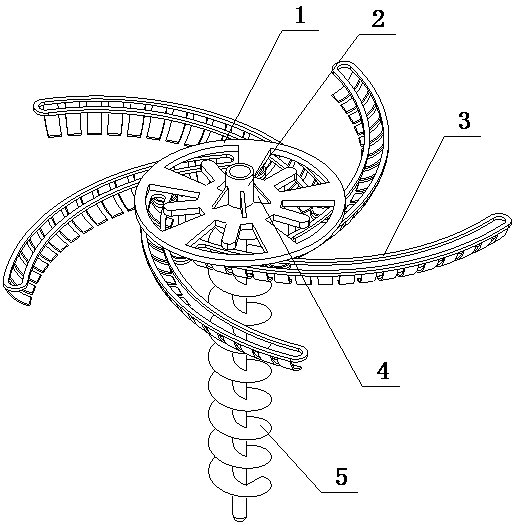

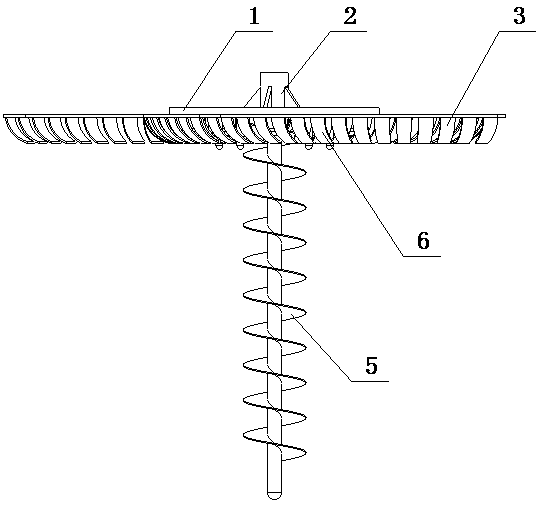

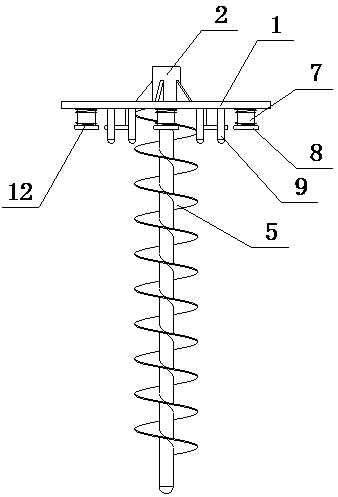

[0019] A flattening mechanism for granary grain in the present invention is realized in the following way: a flattening mechanism for granary grain in the present invention consists of a turntable (1), a coupling sleeve (2), a leveling frame (3), and reinforcing ribs (4), screw shaft (5), curved plate (6), connecting shaft (7), limit cap (8), stirring shaft (9), groove (10), connecting sleeve (11) and spring , one end of the screw shaft (5) is connected to the bottom of the turntable (1), the other end of the screw shaft (5) extends downward, the coupling sleeve (2) is connected to the top of the turntable (1), and the coupling There are reinforcing ribs (4) between the sleeve (2) and the turntable (1), and at least three sets of stirring shafts (9) are placed at the bottom of the turntable (1), and one set of stirring shafts (9) is stirred by at least one Shaft (9), the end surface of the stirring shaft (9) is an arc surface, and one end of at least three connecting shafts (7...

Embodiment 2

[0022] The difference between this embodiment and Embodiment 1 is that a fixed shaft (14) is added on the arc-shaped plate (6), and the flat arc is connected with the flat frame (3) through the fixed shaft (14). A torsion spring (13) is placed on the fixed shaft (14), one end of the torsion spring (13) is connected to the arc plate (6), and the other end of the torsion spring (13) is connected to the leveling frame (3) When in use, the connecting part of the leveling frame (3) and the arc-shaped plate (6) can be changed into an elastic buffer structure, and the rigid impact force it receives when closing the warehouse can be changed into a flexible impact force to improve its service life;

[0023] The design of reinforcing ribs (4) placed between the coupling sleeve (2) and the turntable (1) increases the connection strength between the coupling sleeve (2) and the turntable (1) and stabilizes the hoisting of the device;

[0024] The end surface of the agitating shaft (9) is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com