Material dipping machine for matchstick processing

A dipping and matching technology, which is applied in the field of dipping machines for match processing, can solve the problems of not being able to scrape the medicinal material smoothly, easily sore hands affect work efficiency, and it is difficult to evenly dip the matchstick, so as to avoid the movement of the scraper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

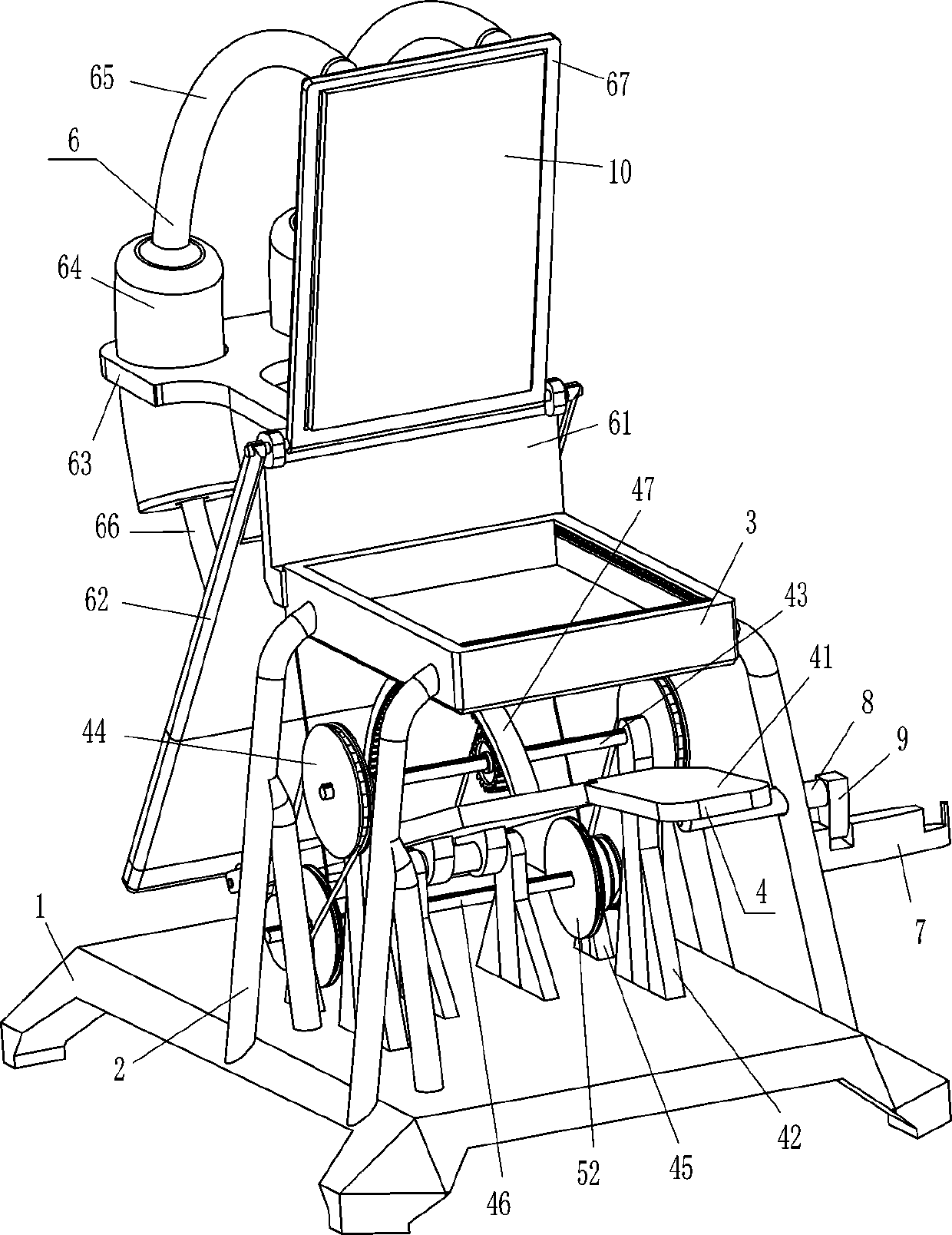

[0022] see Figure 1-Figure 3 , a dipping machine for match processing, including a base 1, a support rod 2, a charging frame 3, a driving mechanism 4 and a scraping mechanism 5, and the top, left and right sides of the base 1 are symmetrically fixed with support rods 2. The charging frame 3 is fixedly connected between the tops of the four support rods 2, the driving mechanism 4 is arranged on the top of the base 1, and the scraping mechanism 5 is arranged between the driving mechanism 4 and the charging frame 3, and the scraping mechanism 5 is connected with the loading frame 3. Material frame 3 cooperates.

[0023] The driving mechanism 4 includes a pedal 41, a support plate 42, a rotating shaft 43, a transmission assembly 44, a support plate 45, a rotating rod 46, an arc-shaped rack 47, a first spring 48 and a gear 49, and a pedal 41 is hinged in the middle of the top of the base 1. An arc-shaped rack 47 is affixed to the middle of the top of the pedal 41, and a support p...

Embodiment 2

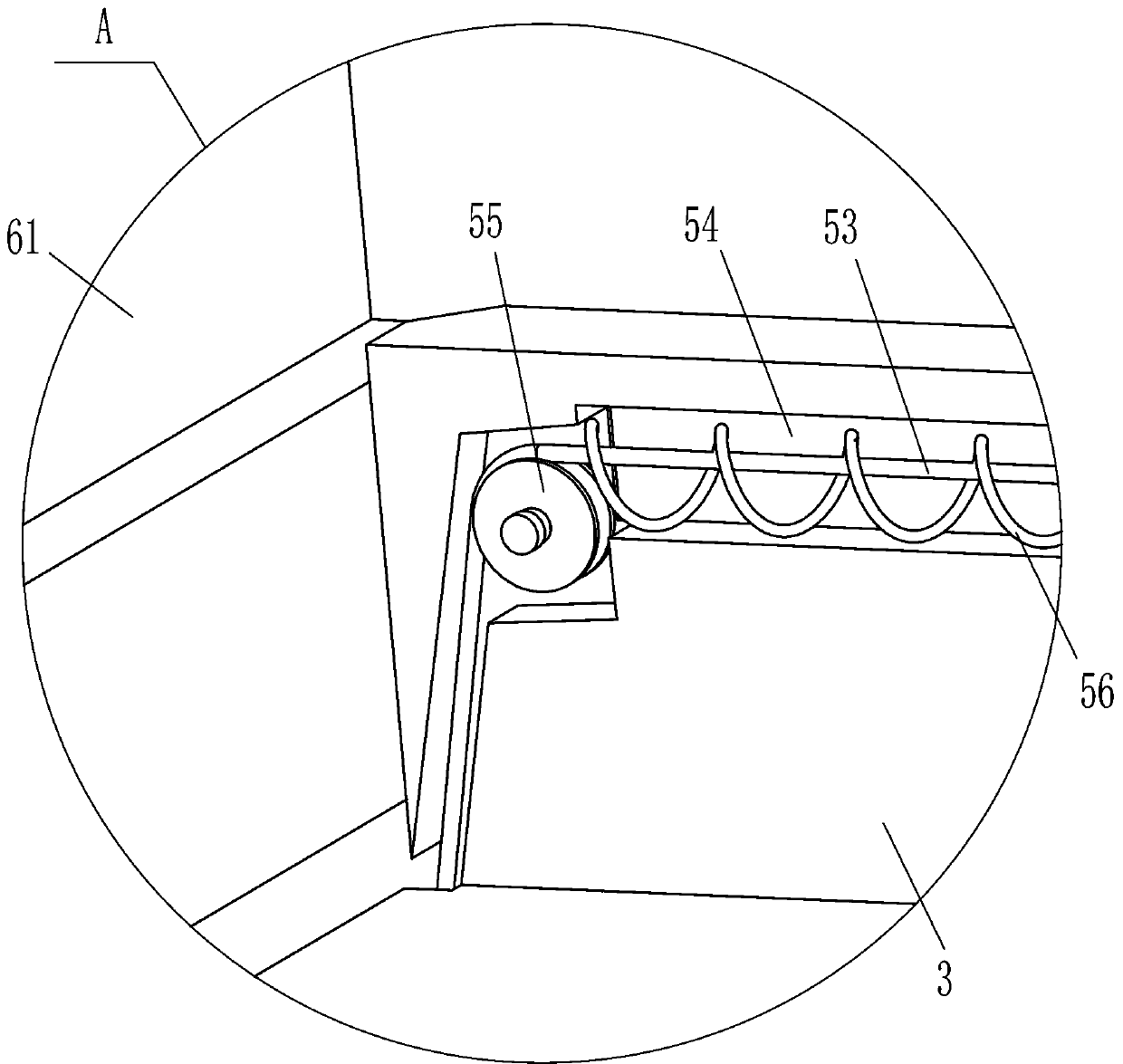

[0029] see figure 1 with figure 2 Compared with Embodiment 1, the main difference of this embodiment is that this embodiment also includes a pressing mechanism 6, and the pressing mechanism 6 includes a vertical plate 61, a swing plate 62, a fixed plate 63, a cylinder body 64, and an arc Tube 65, first piston rod 66, pressing plate 67, second piston rod 68, third spring 69, movable rod 610 and elastic member 611, the outer rear side of charging frame 3 is fixedly connected with riser 61, the middle of riser 61 top A pressure plate 67 is hinged, and a fixed plate 63 is fixedly connected to the upper part of the rear side of the vertical plate 61. The left and right parts of the rear side of the fixed plate 63 are embedded with a cylinder body 64, and the lower part of the cylinder body 64 is slidingly provided with a first piston rod. 66, the bottom of the first piston rod 66 is slidingly provided with a movable rod 610, an elastic member 611 is connected between the top of t...

Embodiment 3

[0032] see figure 1 , figure 2 with Figure 4 , compared with embodiment 1 and embodiment 2, the main difference of this embodiment is that in this embodiment, it also includes a double groove block 7, a blocking rod 8 and a clamping block 9, and the upper part of the right front side support rod 2 is horizontally sliding A retaining rod 8 is provided, and the left part of the retaining rod 8 is in contact with the pedal 41. The right end of the retaining rod 8 is fixedly connected with a block 9, and the lower part of the right front side support rod 2 is fixedly connected with a double groove block 7, and the double groove block 7 Cooperate with the block 9.

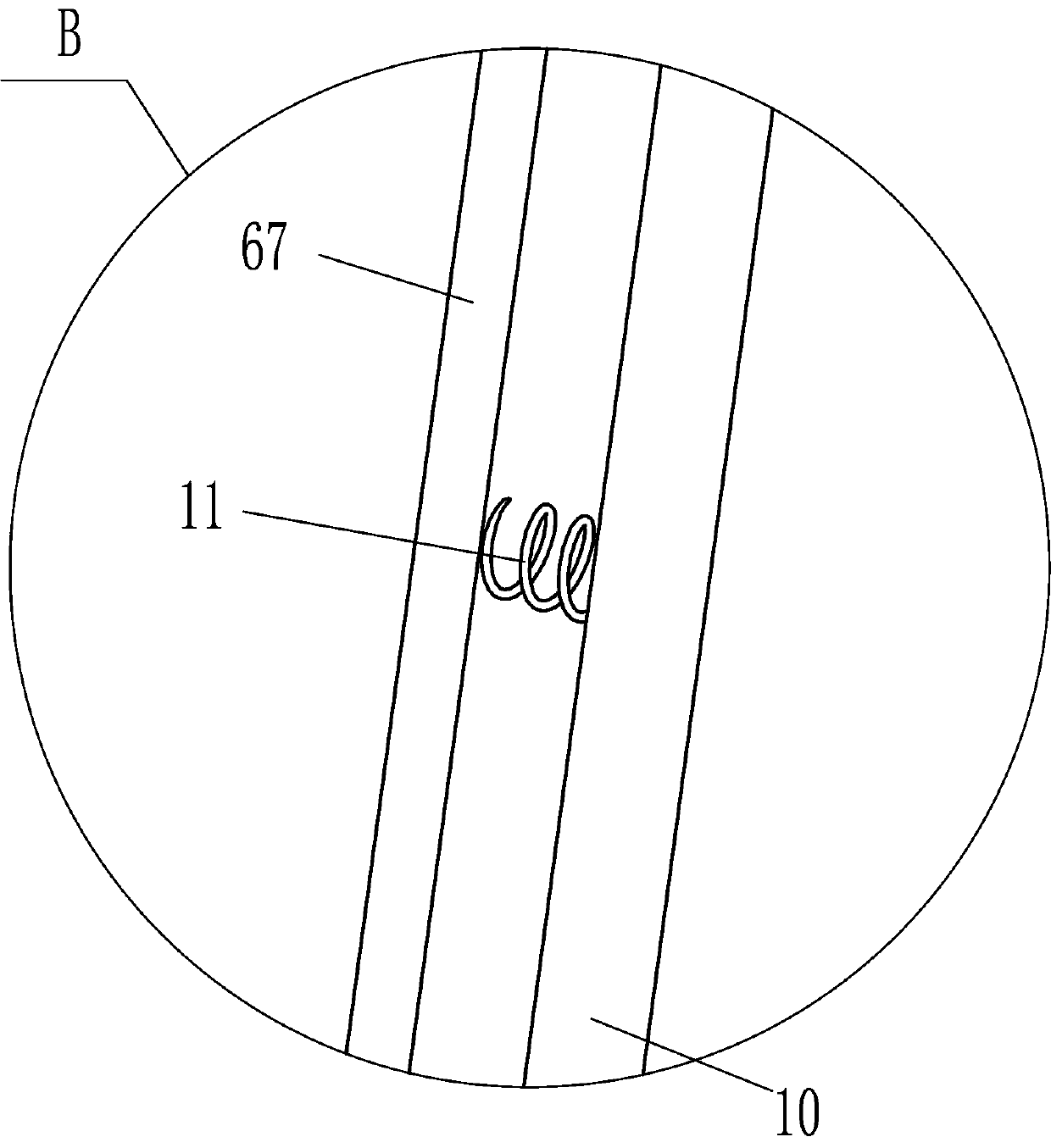

[0033] It also includes a contact plate 10 and a fourth spring 11 , the front side of the pressing plate 67 is slidably embedded with the contact plate 10 , and the fourth spring 11 is evenly spaced between the back side of the contact plate 10 and the inside of the pressing plate 67 .

[0034] When it is necessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com