Acid pickling process method for high-temperature coiled material and application

A high-temperature, pickling technology, applied in the field of pickling, can solve the problems of time-consuming workload, high cost, complex process, etc., and achieve the effects of preventing under-pickling, reducing consumption of hydrochloric acid, and improving pickling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

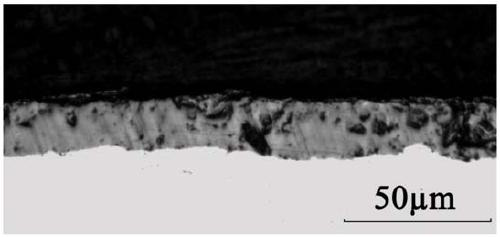

[0046] The thickness of the scale on the surface of the steel strip reaches 18 μm. The peel strength between the scale and the matrix is about 14 MPa.

[0047] 1) The tension control in the tension leveling parameters is based on 15% of the yield limit of the material. The specific tension value is determined by the thickness of the material. Under the action of the tension, the elongation of the strip is about 2%.

[0048] 2) The diameter of the scale-breaking roller of the tension leveler of the unit is 80mm, and the insertion depth of the selected tension leveler is 35mm.

[0049] The speed of the unit for pickling DP0161D1 high temperature coiling material can reach 150mpm. Others are the same as embodiment 1.

Embodiment 3

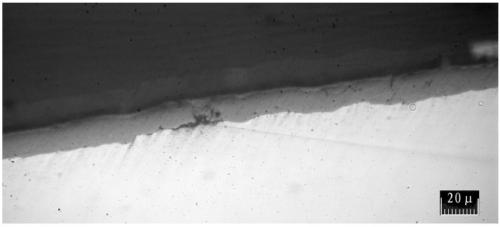

[0051] The thickness of the scale on the surface of the steel strip reaches 18 μm. The peel strength between the scale and the matrix is about 12 MPa.

[0052] 1) The tension control in the tension straightening parameters is based on 16% of the yield limit of the material.

[0053] 2) The diameter of the scale-breaking roller of the tension leveler of the unit is 80mm, and the insertion depth of the selected tension leveler is 42mm.

[0054] The speed of the unit for pickling DP0161D1 high temperature coiling material can reach 150mpm. Others are the same as embodiment 1.

[0055] The present invention can greatly increase the pickling speed of high-temperature coiled material by adjusting the scale breaking parameters of pickling and the process parameters of the acid tank, prevent the steel strip from under-pickling, and can greatly reduce the consumption of hydrochloric acid in the pickling process .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com