Vacuum pre-compression water-drainage consolidation method for uranium tailings mud

A technology of drainage consolidation and tailings slime, which is applied in the field of uranium tailings pond safety, to achieve the effect of saving treatment costs, improving long-term stability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

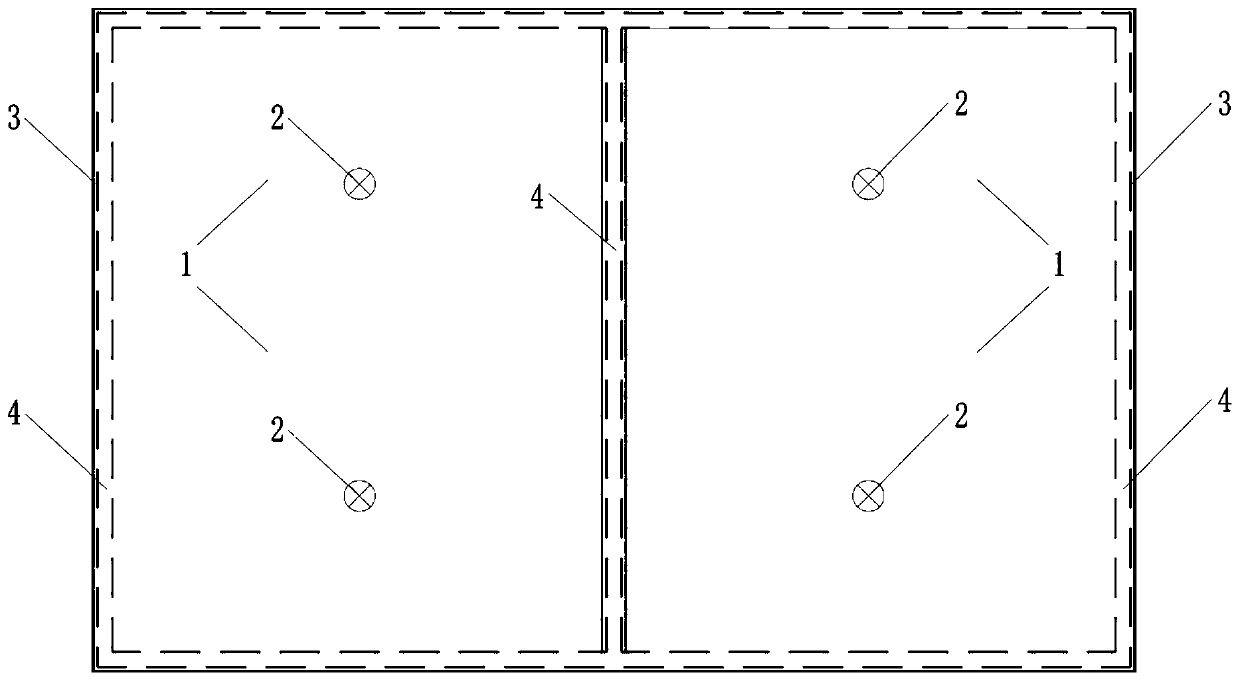

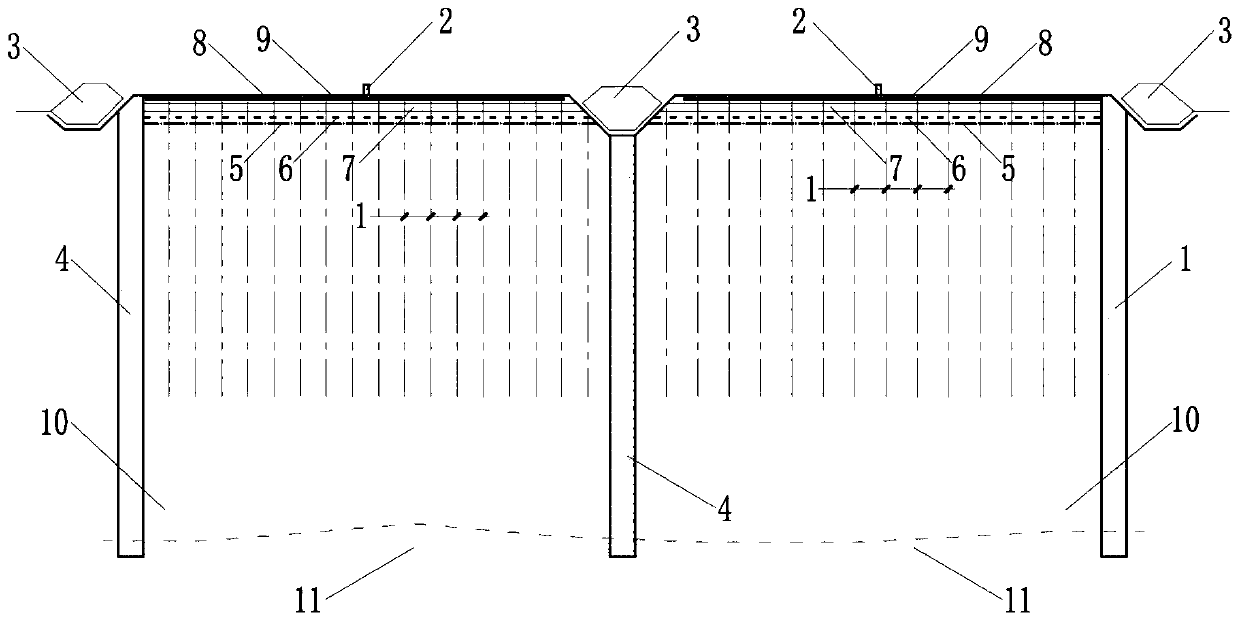

[0055] combine Figure 1-2 , a kind of uranium tailings mud vacuum preloading drainage consolidation method that the present invention proposes, comprises the following steps:

[0056] 1) Beach surface division of tailings reservoir

[0057] Divide tailings reservoir beaches into zones;

[0058] 2) Construction measurement

[0059] Carry out construction positioning and laying out and elevation measurement for each zone;

[0060] 3) lay geotextile 5 and geogrid 6

[0061] Lay geotextiles 5 and geogrids 6 sequentially from bottom to top on the upper part of each partition;

[0062] 4) lay sand cushion 7

[0063] Sand cushion layer 7 is evenly laid on geogrid 6;

[0064] 5) Set up plastic drainage board 1

[0065] Insert the plastic drainage board 1 at the sand cushion 7;

[0066] 6) Build a clay seal wall 4

[0067] Use clay sealing wall 4 to cut off the construction area and non-construction area of each partition, so that the construction area is in a closed state;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com