Riverway sludge removing device

A technology for cleaning device and river channel silt, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc. It can solve the problems of inappropriate setting of filter screens, blockage in pipes, large suction volume, etc. problem, to achieve the effect of keeping the silt suction pipe unobstructed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

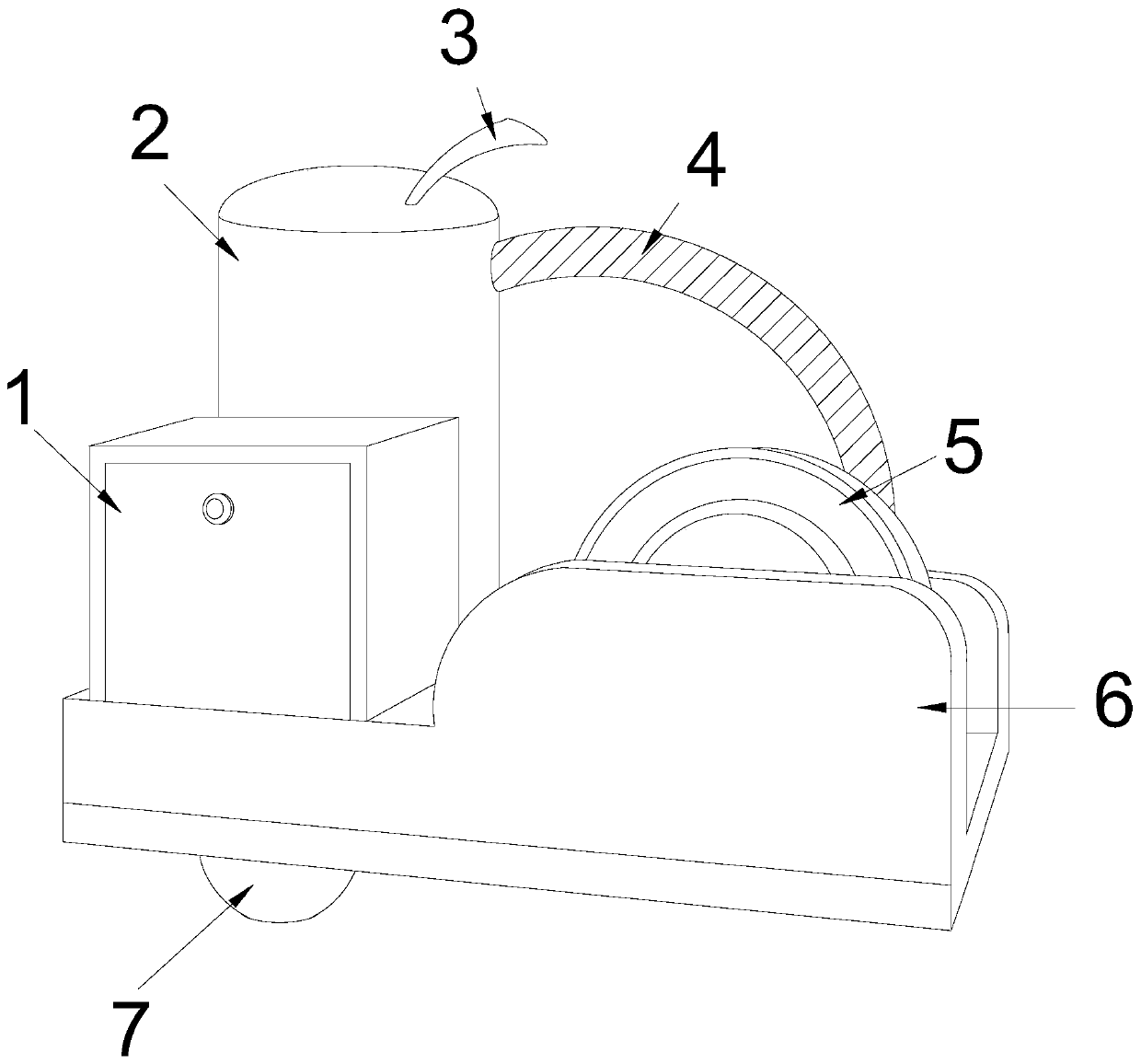

[0030] As attached figure 1 Attached Image 6 Shown:

[0031] The present invention provides a river silt cleaning device, which has a structure including a power box 1, a pressurizer 2, a pressurized spray pipe 3, a suction pipe 4, a pump 5, a support base 6, and a suction rotary device 7. The power box 1 is welded and fixed on the support base 6, the bottom of the press 2 is welded and fixed on the support base 6, and the suction pipe 4 is connected to the pump 5 and the press 2. The pump 5 and the suction rotary device 7 are fixedly connected together, and the pump 5 is welded and fixed on the support base 6.

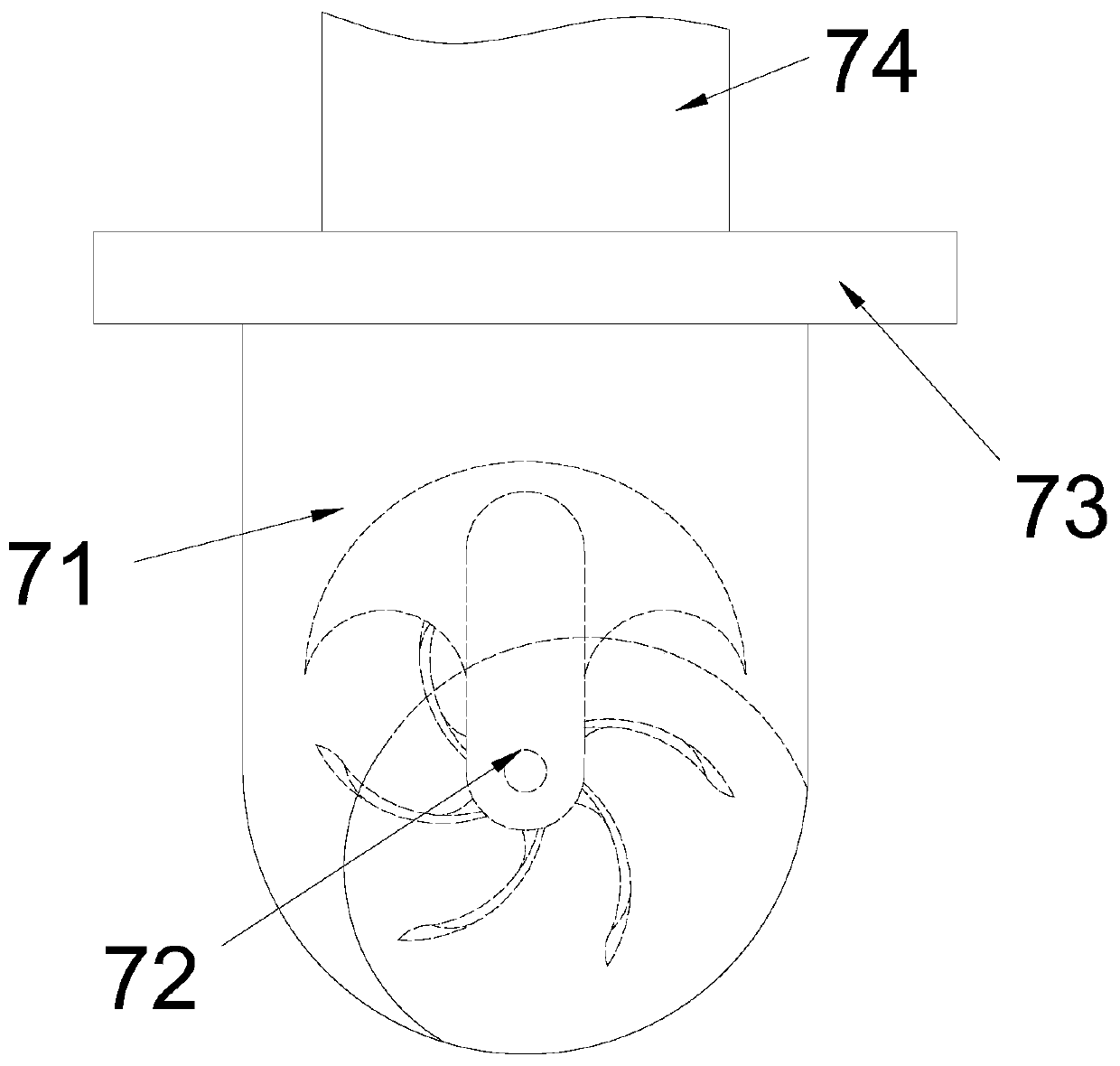

[0032] The suction and rotation device 7 includes a suction isolation sleeve 71, a rotation mechanism 72, a vertical ring 73, and a sludge suction pipe 74. The suction isolation sleeve 71 is welded to the vertical ring 73, and the inside of the suction isolation sleeve 71 A rotary mechanism 72 is provided, and the sludge suction pipe 74 is fixedly connected with the ver...

Embodiment 2

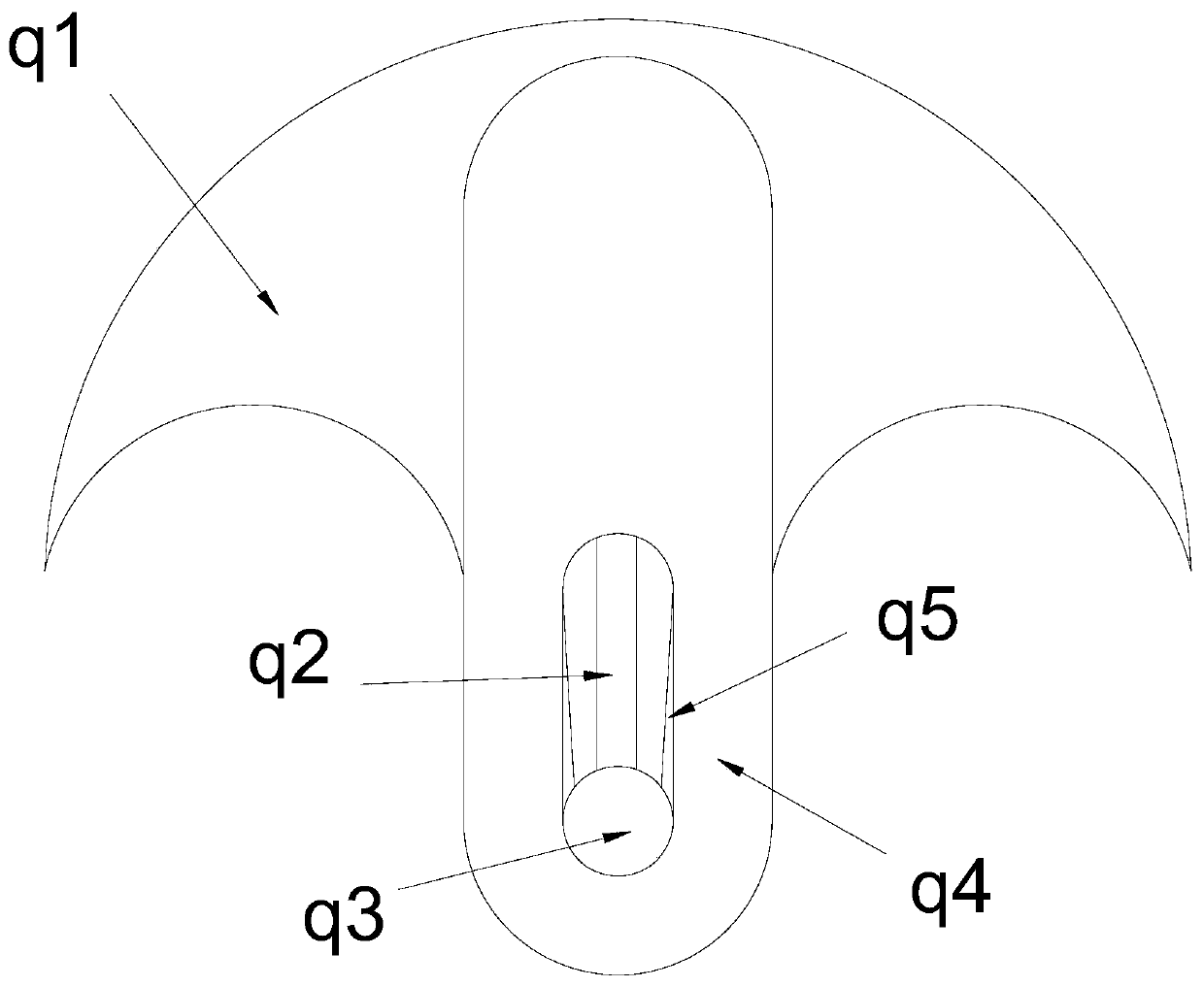

[0040] As attached Figure 7 Attached Figure 8 Shown:

[0041] The present invention provides a device for cleaning river silt. The shifting strip 721 includes an outer shifting piece a1, a floating plate a2, a scale a3, and a connecting strip a4. The floating plate a2 is installed in the middle of the outer shifting piece a1 by embedding. The scale a3 is fixed on the outer surface of the outer paddle a1, the connecting strip a4 is fixedly connected to the outer paddle a1, and the outer paddle a1 has scales a3 that can be rotated on the outer stones and branches. When, it has a strong protective effect.

[0042] Wherein, the bottom of the pressing rod q2 is provided with a semicircular arc sleeve, and the inner surface of the sleeve strip has a smooth coating.

[0043] Wherein, the left and right sides of the floating plate a2 extend out of the inner covering surface of the outer paddle a1, and the left and right sides of the floating plate a2 are in a bare state, which can be ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com