Dredging system for box culvert and continuous construction method thereof

A construction method and box culvert technology, applied in waterway systems, earth movers/excavators, water supply devices, etc., can solve the problem of complex underwater structure of dredging robots, increased device failure points, and easy jamming of the coiling mechanism, etc. Problems, to achieve the effect of solving the inability to realize long-distance transmission, reducing the number of power switching times, and simple power switching methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

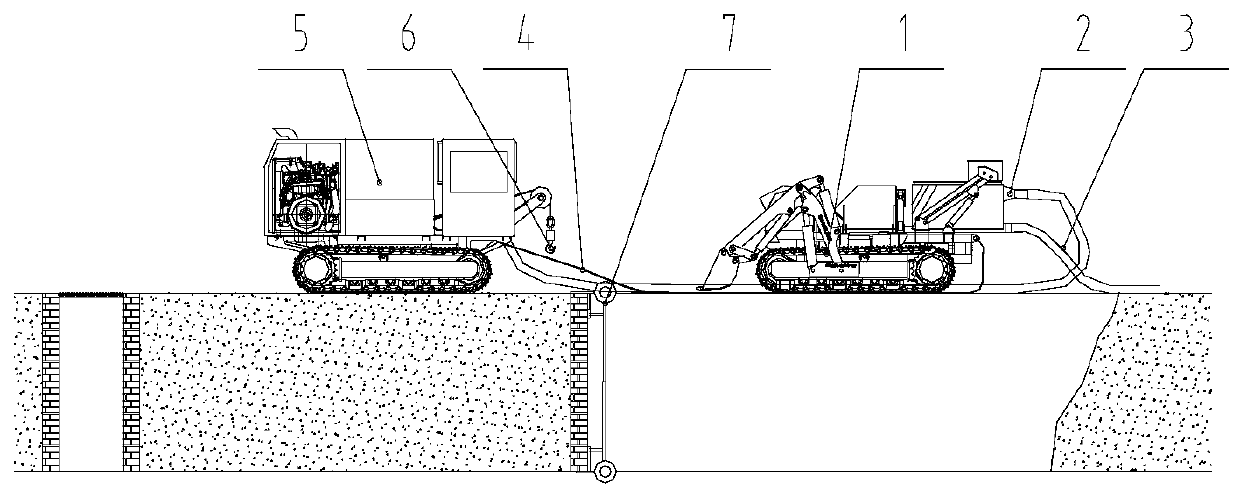

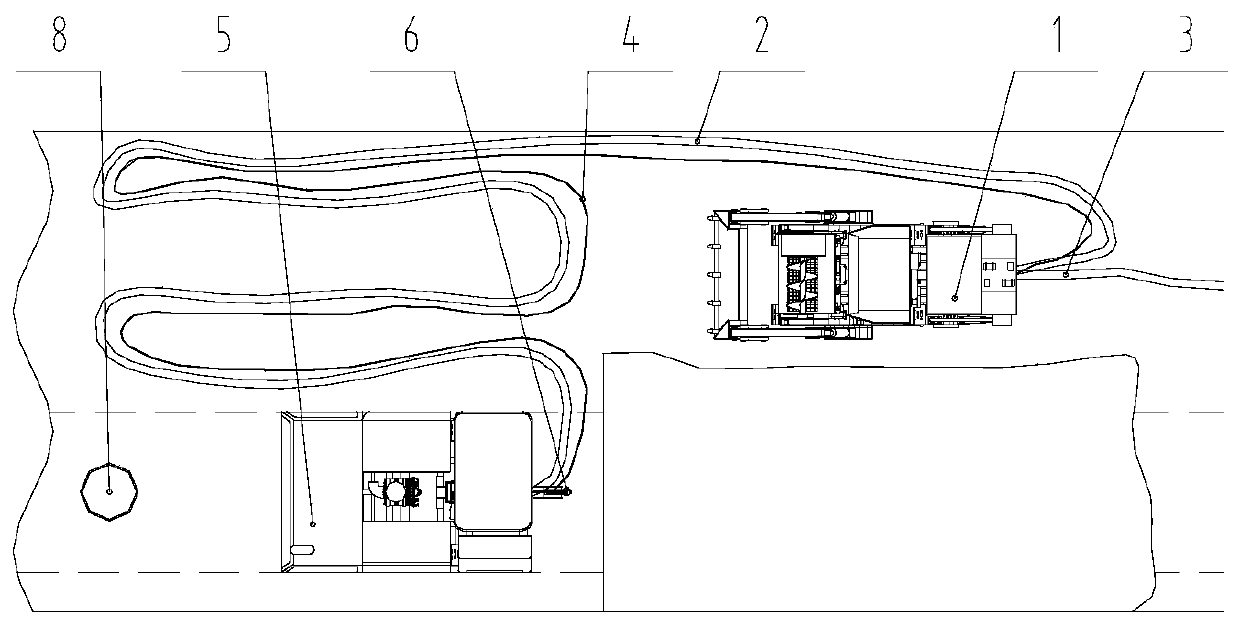

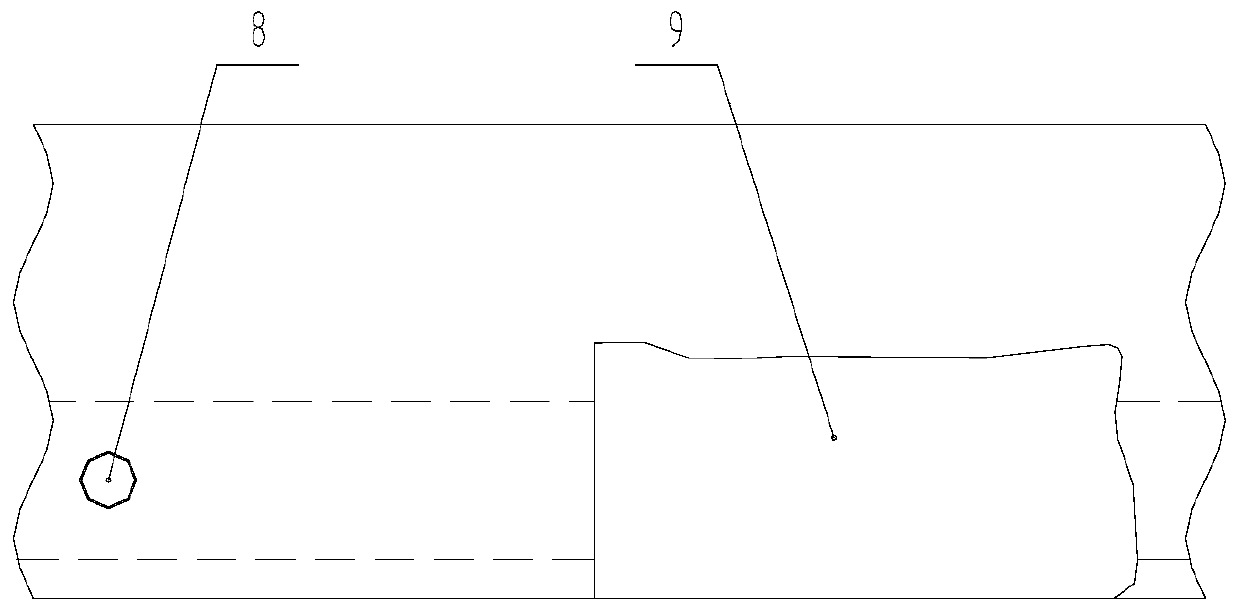

[0041] combine Figure 1-Figure 5 According to one aspect of the present invention, a box culvert dredging system is provided, comprising:

[0042] A dredging robot 1, the dredging robot 1 is used for dredging in the box culvert 10;

[0043] A movable power station 5, which is connected to the dredging robot 1 through a power pipeline 2 to provide power for the dredging robot 1; and

[0044] A traction pipeline 4, which can be used to tow the power pipeline 2, one end of the traction pipeline 4 is connected to the dredging robot 1, and the other end of the traction pipeline 4 is connected to the power station 5 Or the power line 2.

[0045] During the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com