Oil field water injection well high pressure multi-purpose nipple

An oilfield water injection and multi-purpose technology, applied in wellbore/well components, wellbore/well valve devices, measurement, etc., can solve the problems of water injection wells that cannot record oil casing pressure, cannot detect oil casing pressure, and are difficult to replace , to achieve the effect of overcoming the problem of pipeline pressure admission, high-efficiency pipeline pressure admission, and low device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the drawings and embodiments.

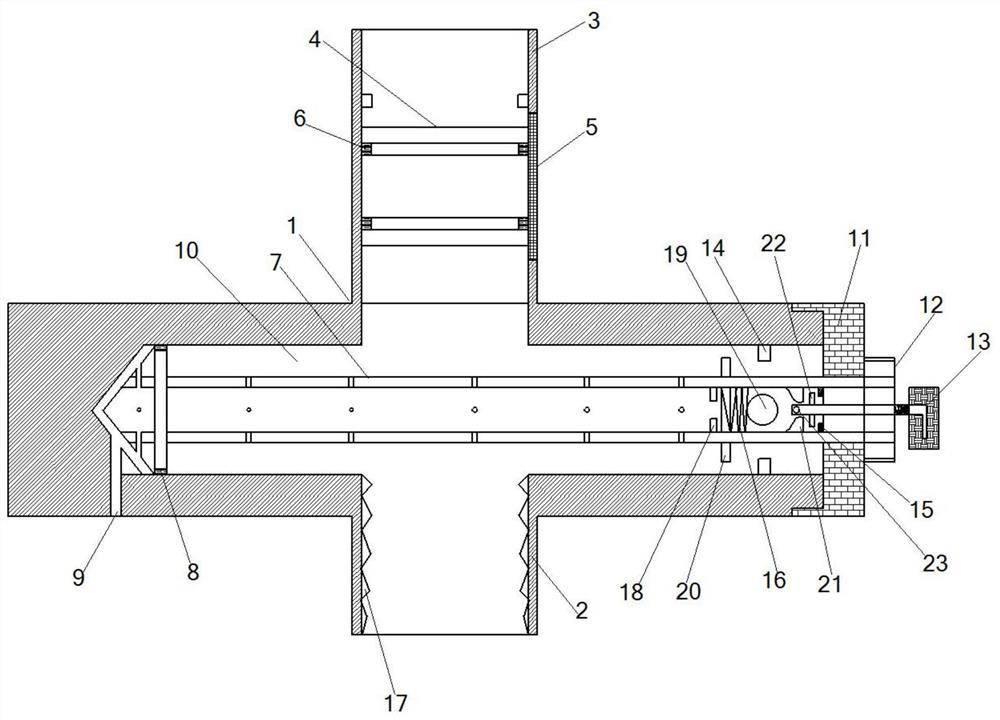

[0020] see figure 1 , oil field water injection well high-pressure multi-purpose sub, including a cross-shaped sub body 1 composed of a vertical rod body and a horizontal rod body, a piston 4 is provided in the inner cavity of the upper section of the vertical rod body, and a pressure gauge nozzle 3 is provided at the upper end of the vertical rod body; A hydraulic oil guide channel 5 is provided on the vertical rod body wall on the side where the piston 4 is running; the lower section of the vertical rod body is a needle valve joint 2; There is a hollow conical spool 7 inside, and the left end of the hollow conical spool 7 is provided with a conical head sealing ring 8; the left end of the conical valve cavity 10 is provided with a vent 9; Press cap 11; the outside of press cap 11 is provided with top scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com