MEMS pump module

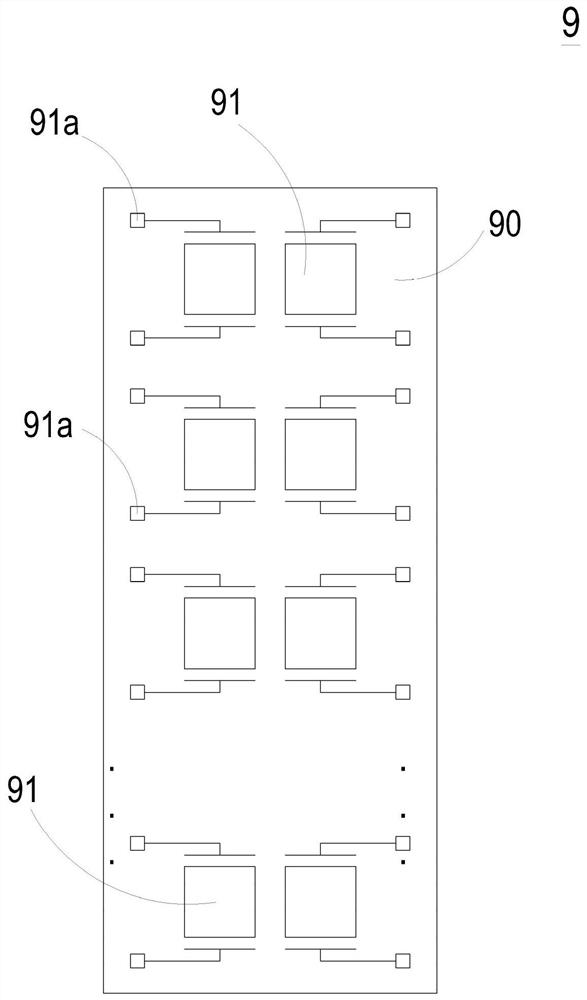

A technology of electric pumps and microcomputers, applied in pumps, pump control, mechanical equipment, etc., can solve problems such as the inability to reduce the chip cost and the large area of the control electrode 91a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments embodying the features and advantages of the present case will be described in detail in the description of the latter paragraph. It should be understood that this case can have various changes in different aspects, all of which do not depart from the scope of this case, and the descriptions and diagrams therein are essentially used for illustration rather than limiting this case.

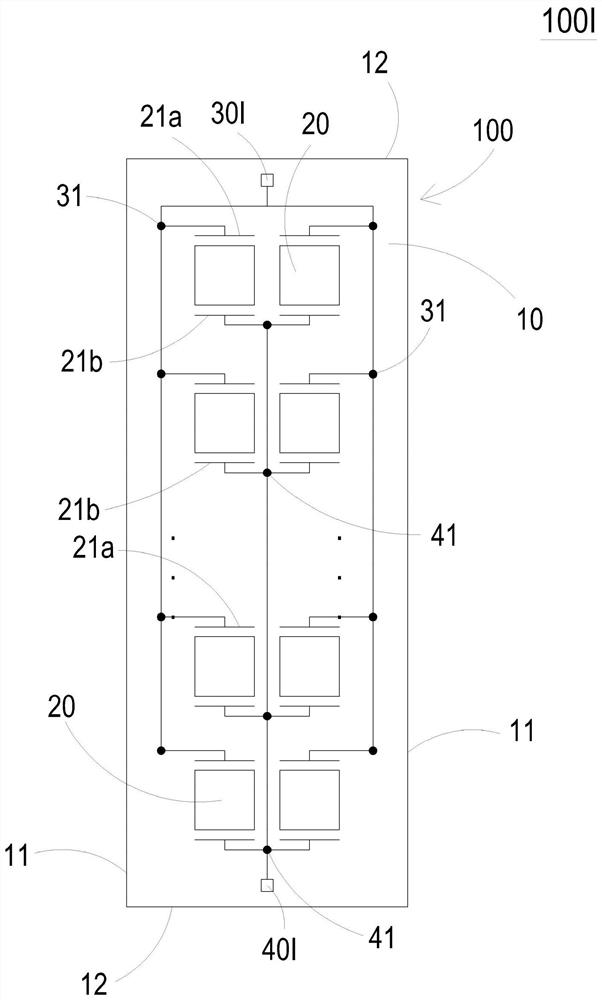

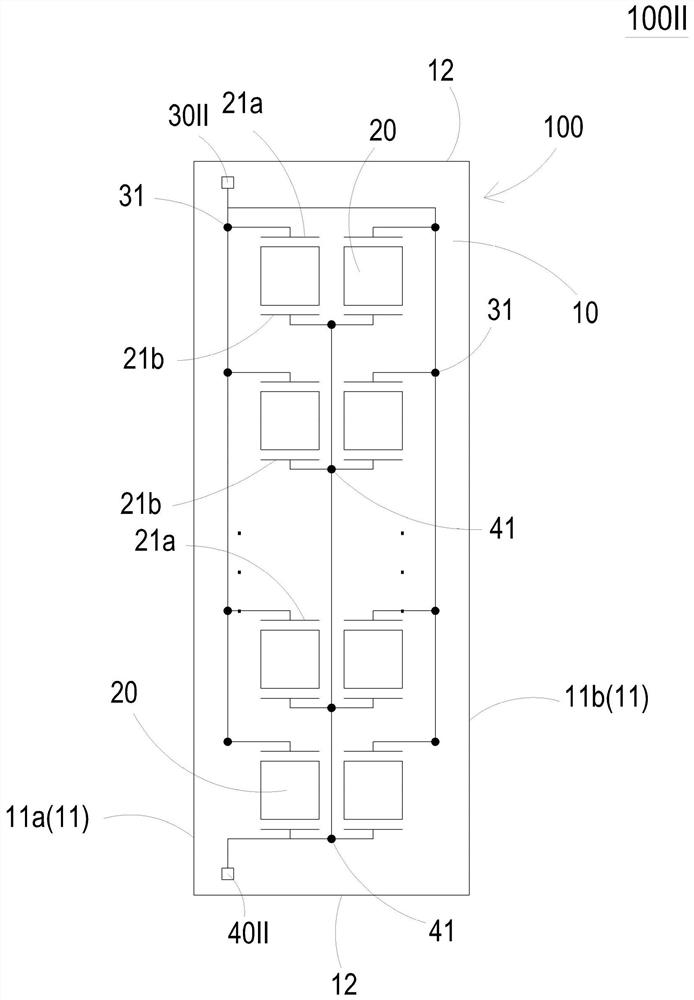

[0022] see figure 2 , In the first embodiment of the present case, the MEMS pump module 100I includes a MEMS chip 100 . The MEMS chip 100 includes a chip body 10 , a plurality of MEMS pumps 20 , at least one first control electrode 30I, a plurality of first connection points 31 , at least one second control electrode 40I and a plurality of second connection points 41 . The chip body 10 has a rectangular shape and has two opposite long sides 11 and two opposite short sides 12 . The MEMS pumps 20 are disposed on the chip body 10 , and each MEMS pump 20 has a first electrode 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com