Preparation method of quaternary ammonium salt modified polyester resin for antibacterial powder coating

A technology of modified polyester and antibacterial powder, applied in the field of powder coatings, can solve the problems of easy migration of antibacterial agents, unsatisfactory economy and safety, decreased antibacterial effect, etc., to reduce costs, safety risks, and requirements of reaction conditions. Low, excellent antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

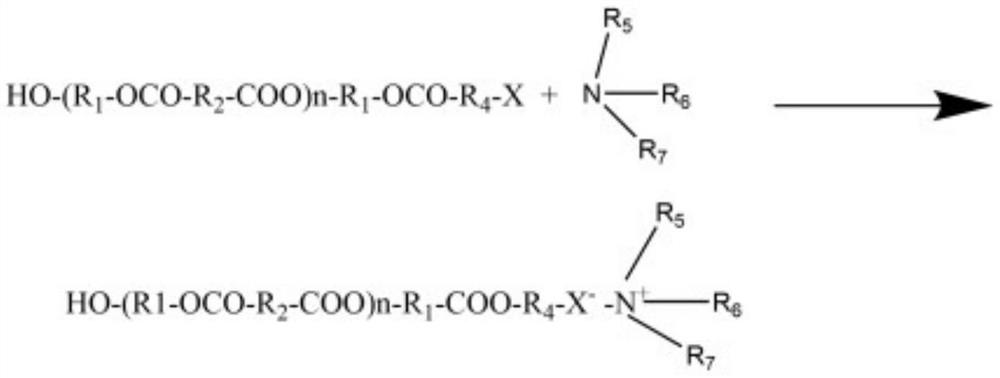

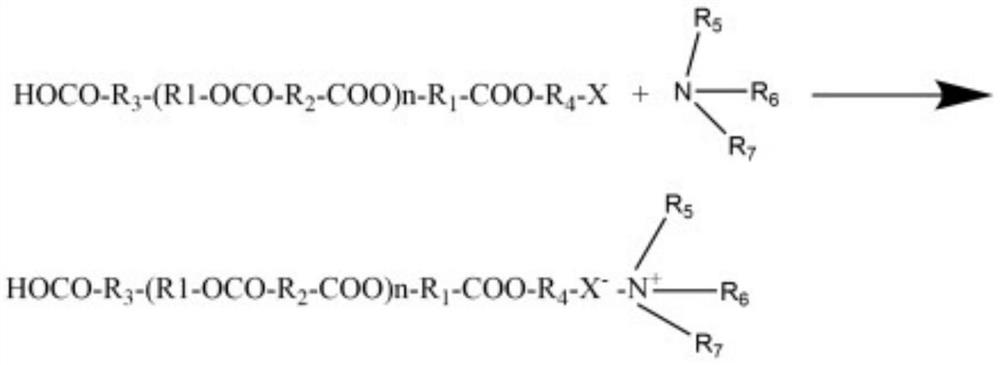

Method used

Image

Examples

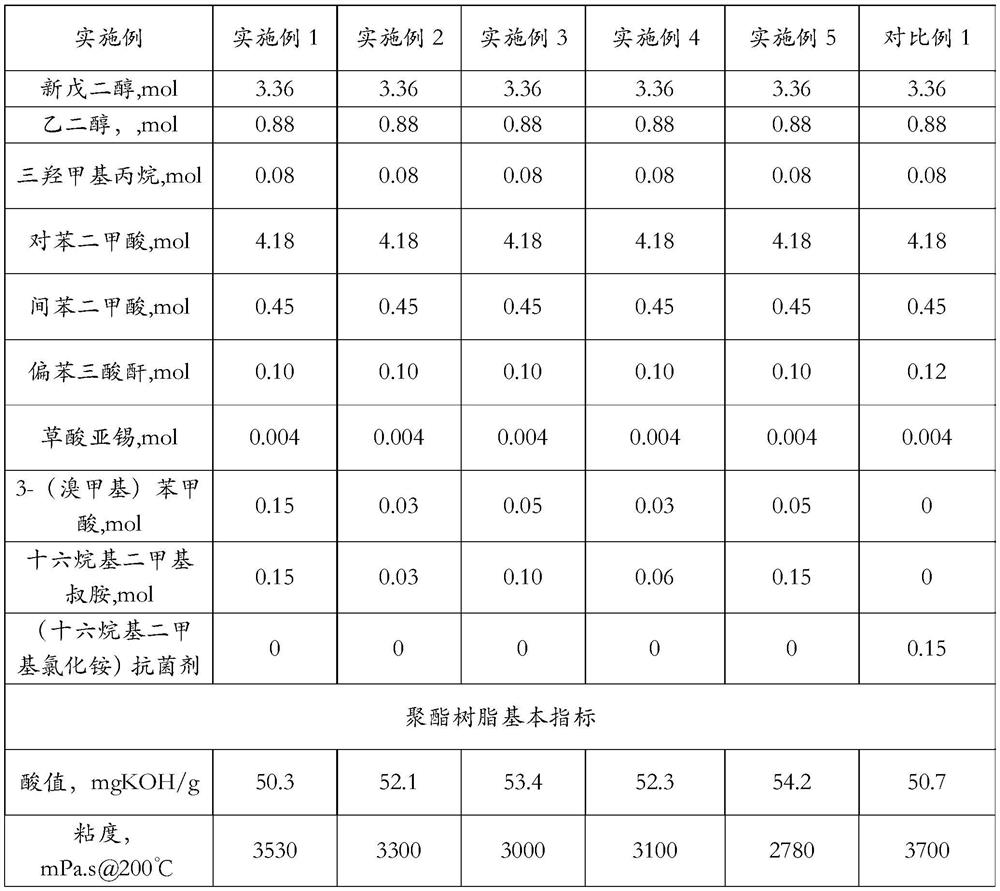

Embodiment 1~5

[0051] The quaternary ammonium salt-modified polyester resin in the examples of this group is a carboxyl-terminated quaternary ammonium salt-modified polyester resin.

[0052] Its preparation comprises the following steps:

[0053] Step S1: After heating the polyol and esterification catalyst with continuous stirring and melting, add polybasic acid and / or acid anhydride, and gradually raise the temperature to 180°C under the protection of nitrogen. During this period, the distillation column is used to distill out the esterification water, and the temperature of the distillation column is controlled at the top of the column. The temperature does not exceed 102°C to prevent the distillation of materials other than esterified water;

[0054] Step S2: After the temperature in step S1 rises to 220°C to 250°C, keep warm, wait until the material is clear and transparent, and basically no esterified water distills out, then cool down to 190°C to 210°C, add an end-capping agent, and c...

Embodiment 6~10

[0080] The difference between this group of examples and Examples 6-10 is that the end-capping agent in this group of examples is isophthalic acid.

[0081] The materials and molar amounts of each component in each embodiment are shown in Table 3 below.

[0082] The relevant performances of the carboxyl-terminated quaternary ammonium salt-modified polyester resins prepared in each embodiment were tested, and the test results are shown in Table 3 below.

[0083] Use the carboxyl-terminated quaternary ammonium salt-modified polyester resin prepared in Examples 6-10 to prepare powder coatings and coatings.

[0084] Preparation of powder coating: a, the carboxyl-terminated quaternary ammonium salt modified polyester resin prepared in 558g embodiment 6~10, 42gTGIC, 250g titanium dioxide, 136g precipitated barium sulfate, 10g leveling agent, 4g benzoin weighed and Pre-mixing; b. Melting and extruding the pre-mixed mixture through an extruder; c. Cooling and pressing tablets; d. Cru...

Embodiment 11~15

[0097] The quaternary ammonium salt-modified polyester resin in this group of examples is a hydroxyl-terminated quaternary ammonium salt-modified polyester resin.

[0098] Its preparation comprises the following steps:

[0099] Step S1: After the polyol and esterification catalyst are heated and continuously stirred and melted, the polybasic acid and / or acid anhydride is added, heated to 180°C under the protection of nitrogen, and the temperature is gradually raised. Prevent distillation of materials other than esterification water;

[0100] Step S2: keep warm when the temperature rises to 220-250°C, wait until the material is clear and transparent, and basically no esterification water distills out;

[0101] Step S3: Cool down to 200°C, add halomethyl carboxylic acid compound, keep warm at 220°C-240°C for 1-2h, then distill under reduced pressure at -0.095MPa--0.1MPa for 1-2h, take samples to measure the acid value, when acid After the value is below 5mgKOH / g, return to nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com