Gas pressure protection device

A protection device and gas pressure technology, applied in the field of anaerobic treatment, can solve problems such as the inability to adjust the upper limit of the pressure, and achieve the effects of avoiding the upper limit change of the gas storage pressure, improving safety, and maintaining a constant threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

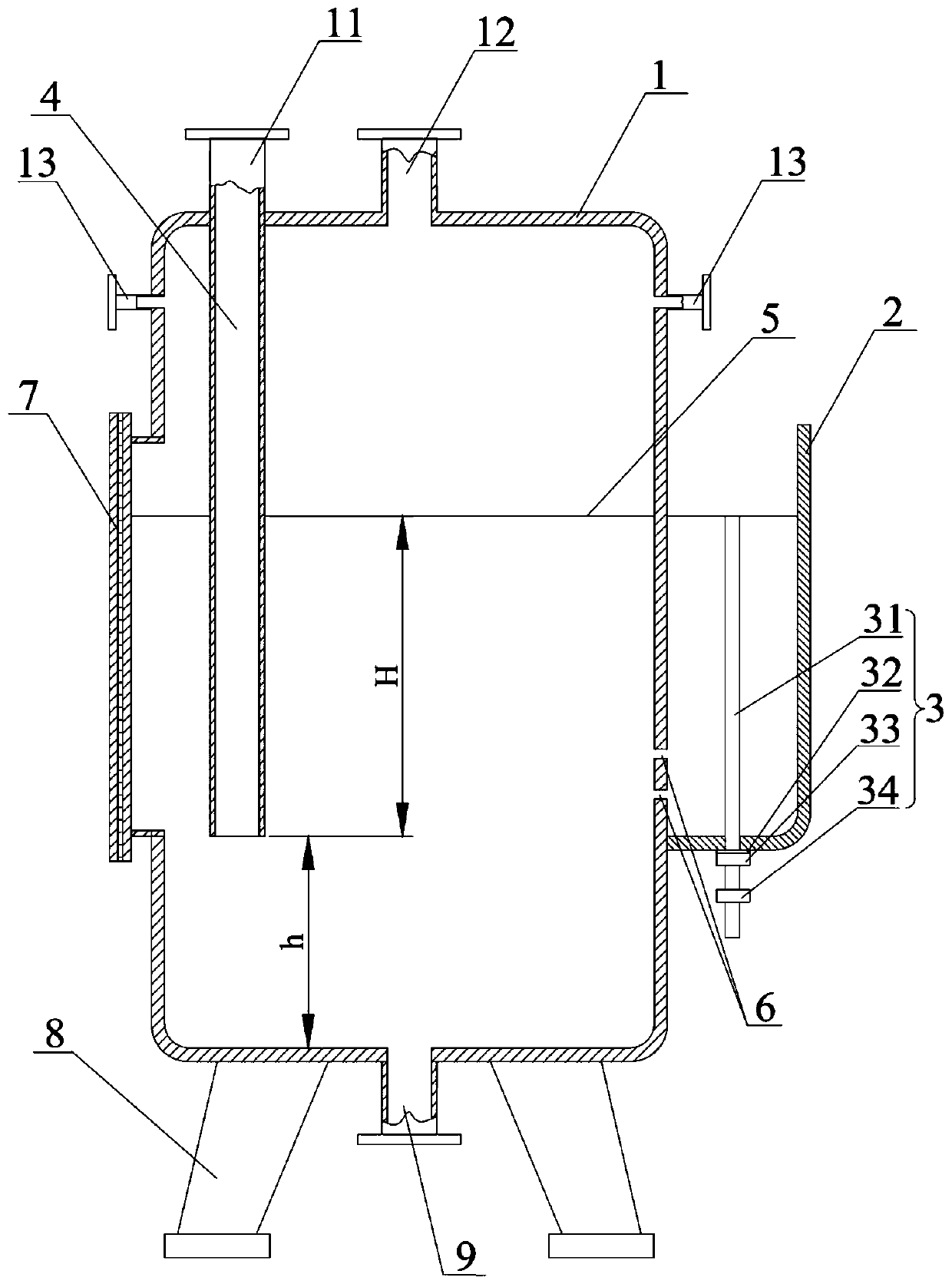

[0038] Such as figure 1 As shown, this embodiment provides a gas pressure protection device, which includes a tank body 1 and a water level adjustment assembly 3, a liquid is arranged in the tank body 1, an air inlet 11 and an air outlet 12 are arranged on the tank body, and the air inlet 11 is connected with a pressure-limiting tube 4, and the gas outlet end of the pressure-limiting tube 4 stretches into the liquid in the tank body 1. The water level adjustment assembly 3 includes a water level adjustment tube 31 , the height of the upper end surface of the water level adjustment tube 31 is adjustable, and the lower end surface of the water level adjustment tube 31 extends out of the tank body 1 .

[0039] In the gas pressure protection device provided in this embodiment, a liquid is provided in the tank body 1 , a pressure limiting tube 4 is connected to the air inlet, and the gas outlet end of the pressure limiting tube 4 extends into the liquid in the tank body 1 . The ga...

Embodiment 2

[0061] In another optional embodiment of the present invention, the water level regulating pipe 31 may be directly connected to the bottom of the connecting body 2 in a sealed manner through a sealing member. By setting a through hole at the bottom of the connecting body 2, the seal is set as a rubber plug, the rubber plug is in an interference fit with the through hole, and a connecting hole is set in the middle of the rubber plug, the water level regulating pipe 31 can pass through the connecting hole, and is connected with the connecting hole. Connection hole interference fit connection. When adjusting the height of the upper end surface of the water level regulating pipe 31 in the connecting body 2, an upward or downward force can be applied to the water level regulating pipe 31 on the outside of the rubber plug by means of external force to adjust the upper end surface of the water level regulating pipe 31 in the connecting body 2 high. Through the rubber plug, the heigh...

Embodiment 3

[0063]The difference between this embodiment and Embodiment 1 is that the tank body 1 and the connecting body 2 in this embodiment are set separately, the bottom of the connecting body 2 is slightly lower than the gas outlet end of the pressure limiting tube 4 in the tank body 1, and the tank body 1 and the connecting body 2 are connected. Two connecting holes are respectively arranged on the opposite side walls of the body 2, and the diameter of the connecting holes is 6mm-10mm. Then connect the corresponding connecting holes one by one through the two connecting pipes, so as to realize the communication between the tank body 1 and the connecting body 2 and to suppress the fluctuation of the water surface in the connecting body 2 when the pressure limiting pipe 4 is depressurized and exhausted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com