Diaphragm air pressure tank and safety detection method thereof

A technology of safety detection and pressure tank, which is applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc. It can solve the problem that the diaphragm pressure tank cannot provide the expected pressure stabilization and buffering function and affect the external pipe network system Water supply stability and other issues, to achieve the effect of good practicability and flexibility of use, good flexibility of use, and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] Example one:

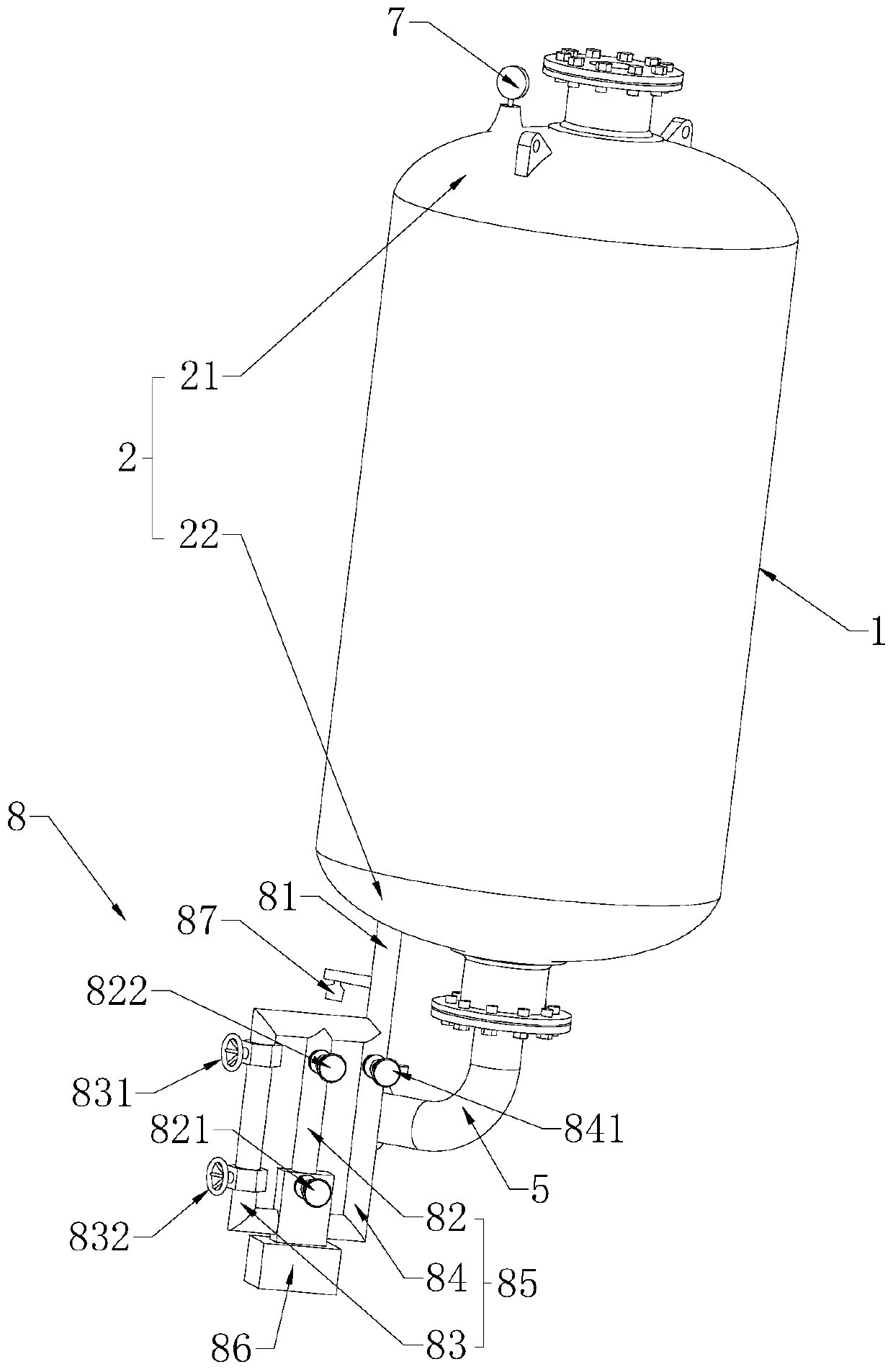

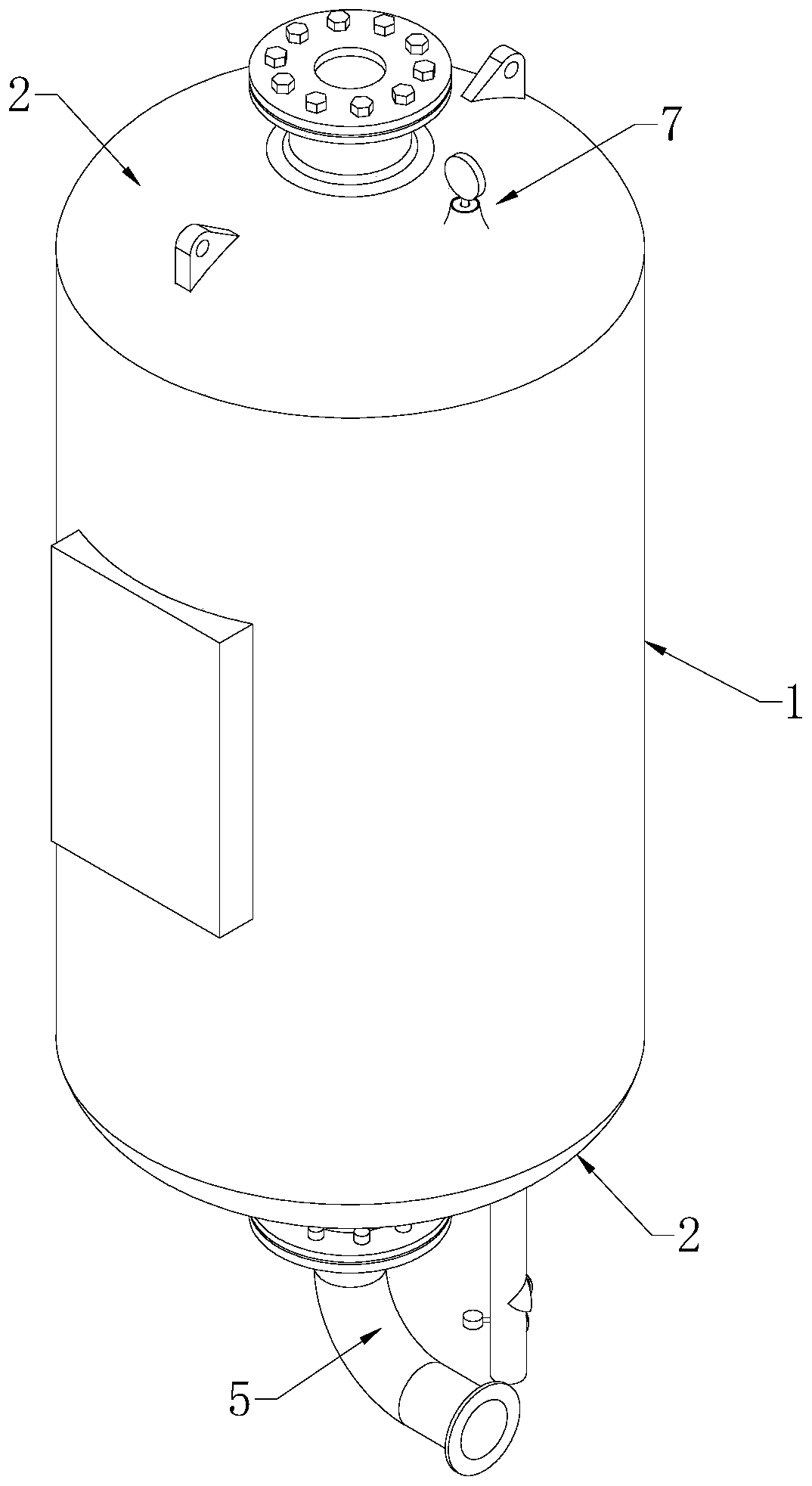

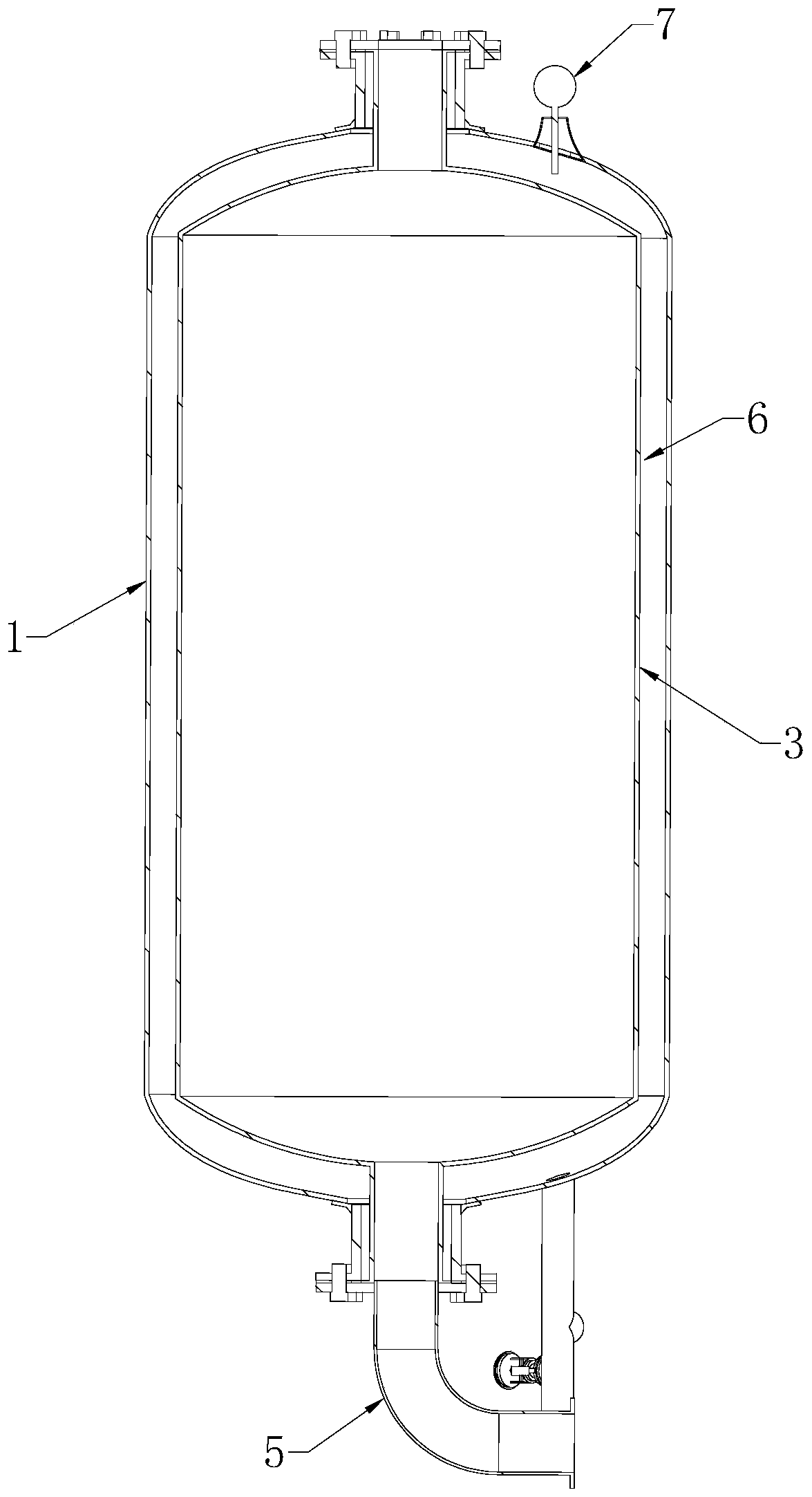

[0040] Combine figure 1 with image 3 As shown, a diaphragm gas pressure tank includes a can body 1 arranged vertically. The can body 1 has an upright cylindrical structure. The upper and lower ends of the can body 1 are welded with heads 2 which are in a bowl structure. A capsule 3 is installed inside the can body 1, and two ends of the capsule 3 are respectively penetrated with a corresponding head 2 and are fixedly connected with the head 2 through a flange. The head 2 includes an upper head 21, a head 2 and a lower head 22, a head 2, and the flange at the head 2 of the upper head 21 and the upper end of the capsule 3 are locked and sealed by bolts. Head 2; lower head 22 The flange at the head 2 and the lower end of the capsule 3 are connected by bolts to form an opening. The inlet and outlet pipes 5 are welded and installed at the openings. The inlet and outlet pipes 5 pass through the lower head 22 and communicate with the capsule 3, and the inlet and...

Example Embodiment

[0049] Embodiment two:

[0050] Such as Figure 5 As shown, a safety detection method for a diaphragm pressure tank includes the following steps:

[0051] S1. Perform flaw detection on the welded tank body 1. After the flaw detection is passed, the tank body 1 is assembled with the capsule 3. Then the main structure of the assembled diaphragm pressure tank is inflated, and the display state of the pressure gauge 7 is observed after the inflation is completed. It is necessary to observe whether it can display the pressure value normally, whether there is the phenomenon of the pointer swinging, if it can not display normally or the pointer swinging, the pressure gauge 7 needs to be replaced.

[0052] S2. Inject water into the main structure of the diaphragm pressure tank that has completed the display test of the pressure gauge 7 and detected normal, and observe the working status of the pressure gauge 7 during the water injection process and within the stable time period after the wat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap