Karst tunnel biaxial loading test device and test method

A test device and test method technology, applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., to achieve high safety factor, facilitate observation of the inside of the test, and not easy to break instantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

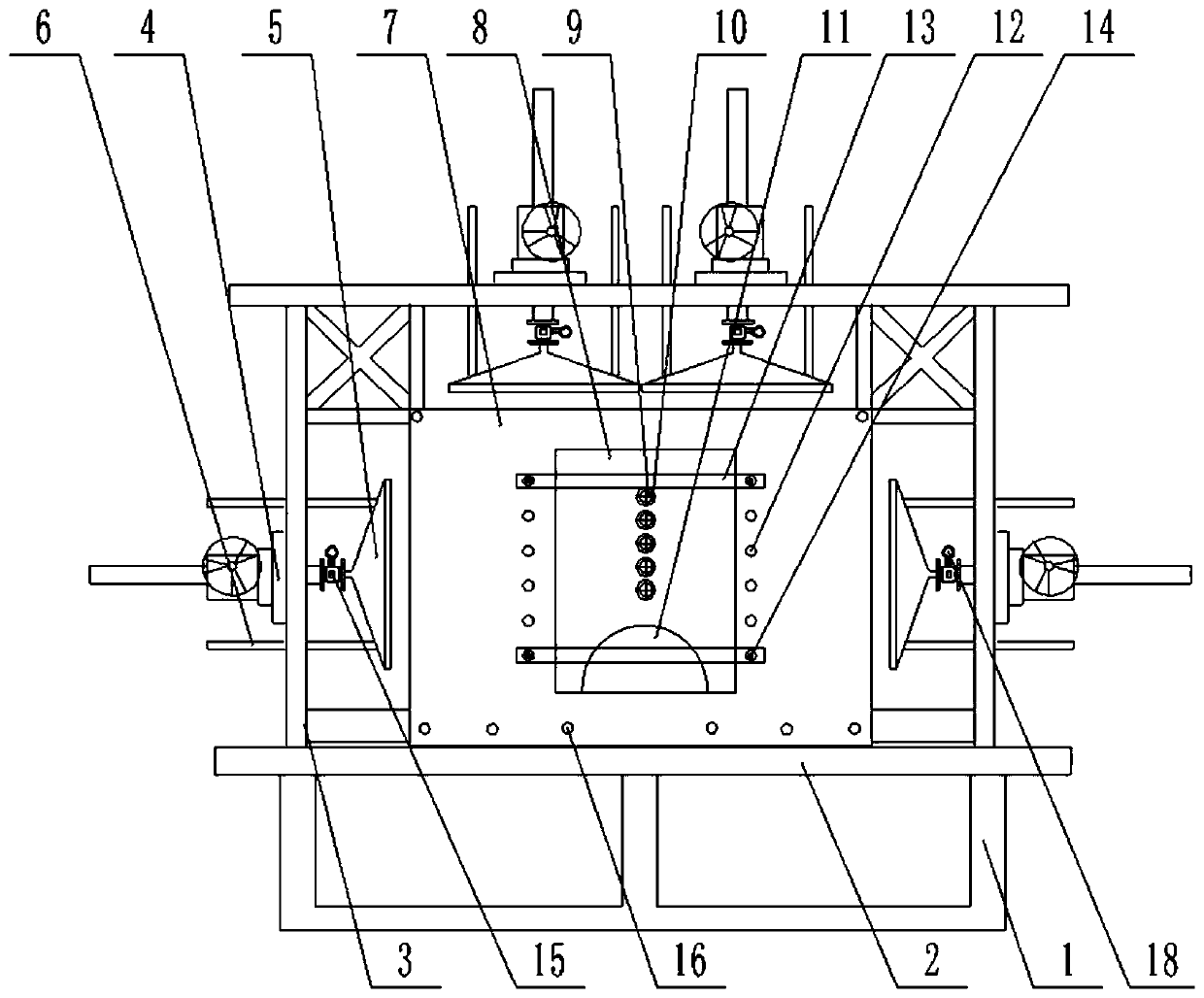

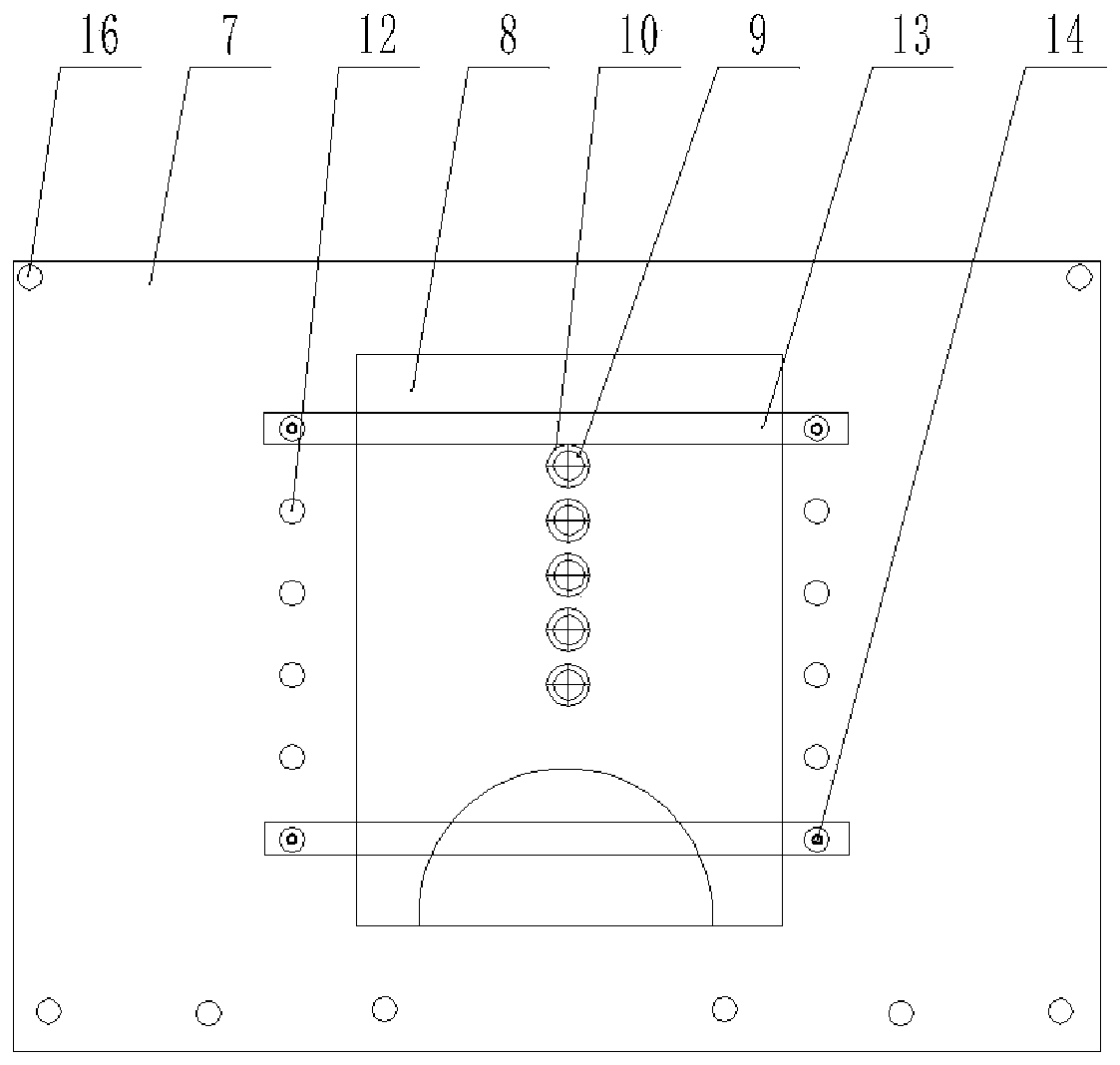

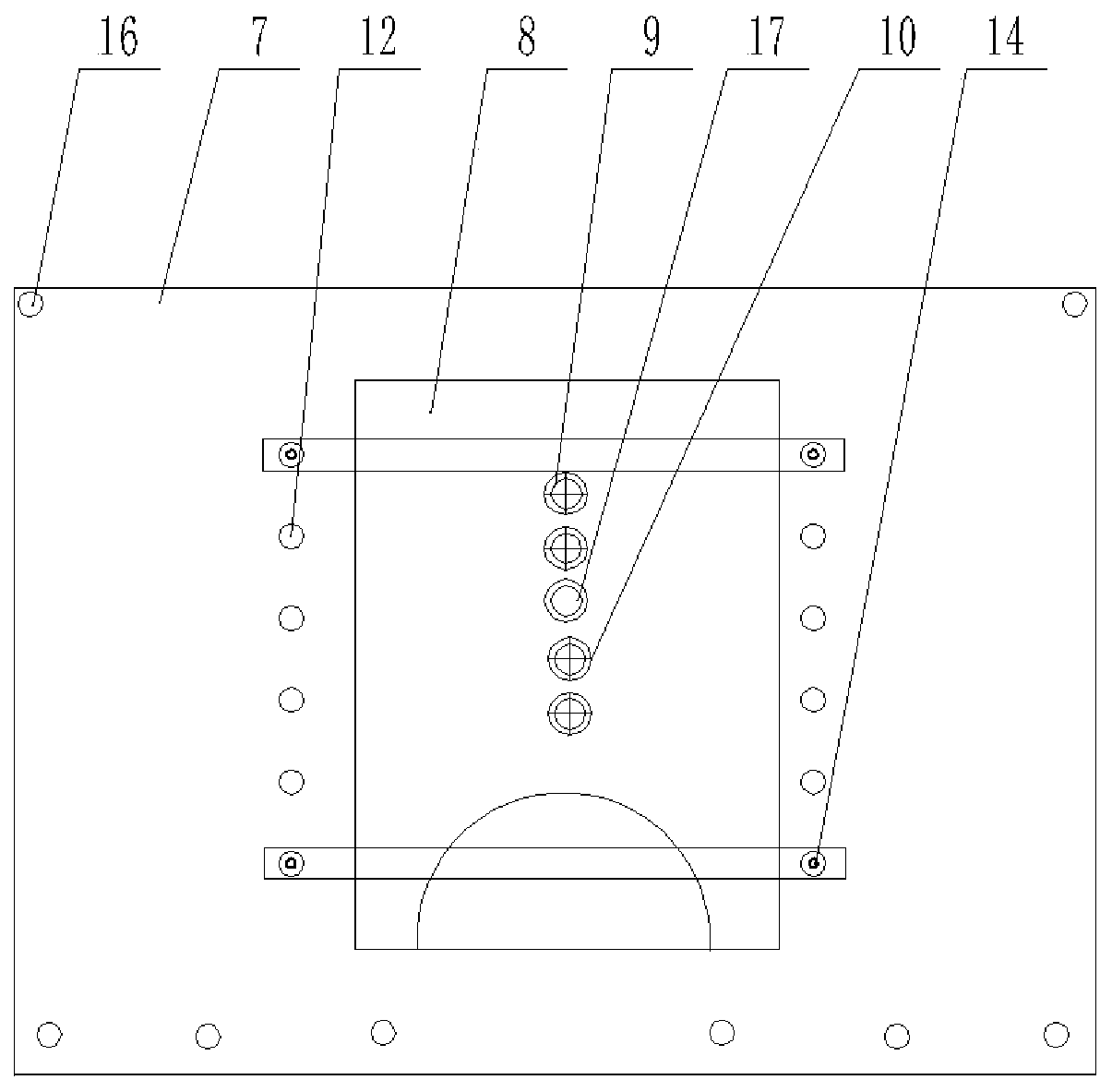

[0031] A karst tunnel biaxial loading test device comprises a base 1, a table 2 is laterally arranged on the upper end of the base 1, a frame 3 is arranged on the table 2, and a plurality of turbine screw lifts 4 are arranged on the upper side and left and right sides of the frame 3, and the turbine The telescopic end of the screw lift 4 is located in the frame 3, and the telescopic end of the turbine screw lift 4 is connected to the pressure plate 5. The two sides of the pressure plate 5 are provided with guide rods 6, and the other end of the guide rod 6 passes through the frame 3 and can pass through the frame 3. Sliding up and down, the front side and rear side of the frame 3 are connected with a surrounding steel plate 7, a glass plate 8 is embedded on the surrounding steel plate 7, and a number of reserved water injection holes 9 are vertically arranged in the middle of the front side glass plate 8, The reserved water injection hole 9 is provided with a tightened first bo...

Embodiment 2

[0035] Preferably, a pressure sensor 15 is provided between the turbine screw lift 4 and the pressure plate 5 , and the pressure sensor 15 is connected to a pressure digital display 18 .

[0036] Setting the pressure sensor 15 between the turbine screw lift 4 and the pressure plate 5 can monitor the loading force of the turbine screw lift 4 and display it in real time through the pressure digital display 18 so as to make adjustments according to the situation.

[0037] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0039] Preferably, the enclosure steel plate 7 and the frame 3 are connected by third bolts 16 .

[0040] The enclosure steel plate 7 is connected with the frame 3 through the third bolt 16, and the various parts of the test device are integrated into a whole, which increases the overall stability and ensures the test effect.

[0041] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com