Transformer station capacitive equipment insulation performance on-site on-line evaluation device

A technology of capacitive equipment and insulation performance, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of ignoring real-time data analysis and hardware reasoning, untimely acquisition of equipment insulation information, and poor timeliness, so as to facilitate upgrades and transplantation, avoiding detection difficulties, and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

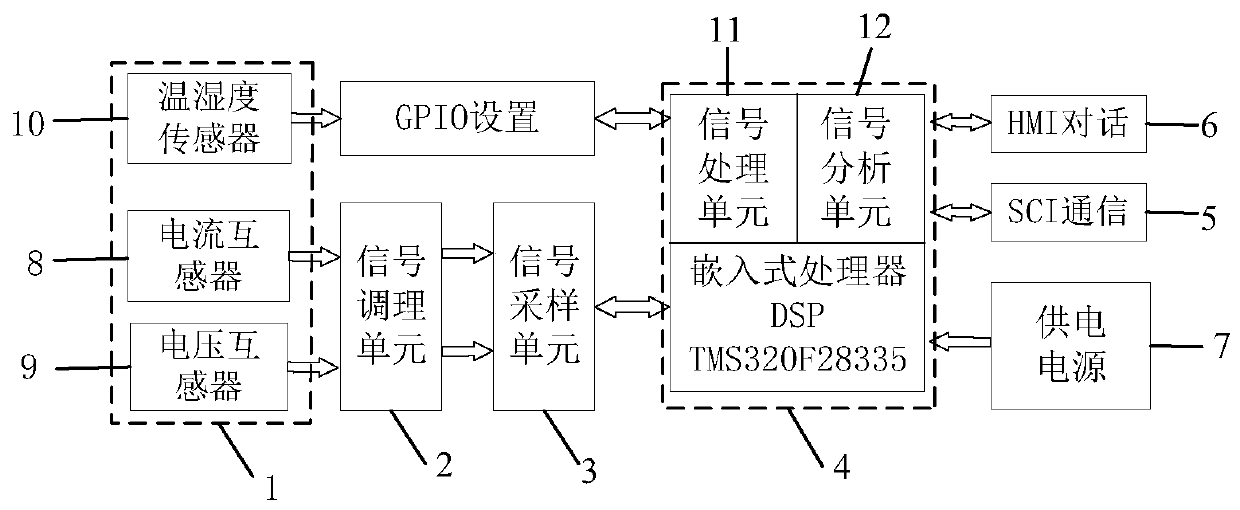

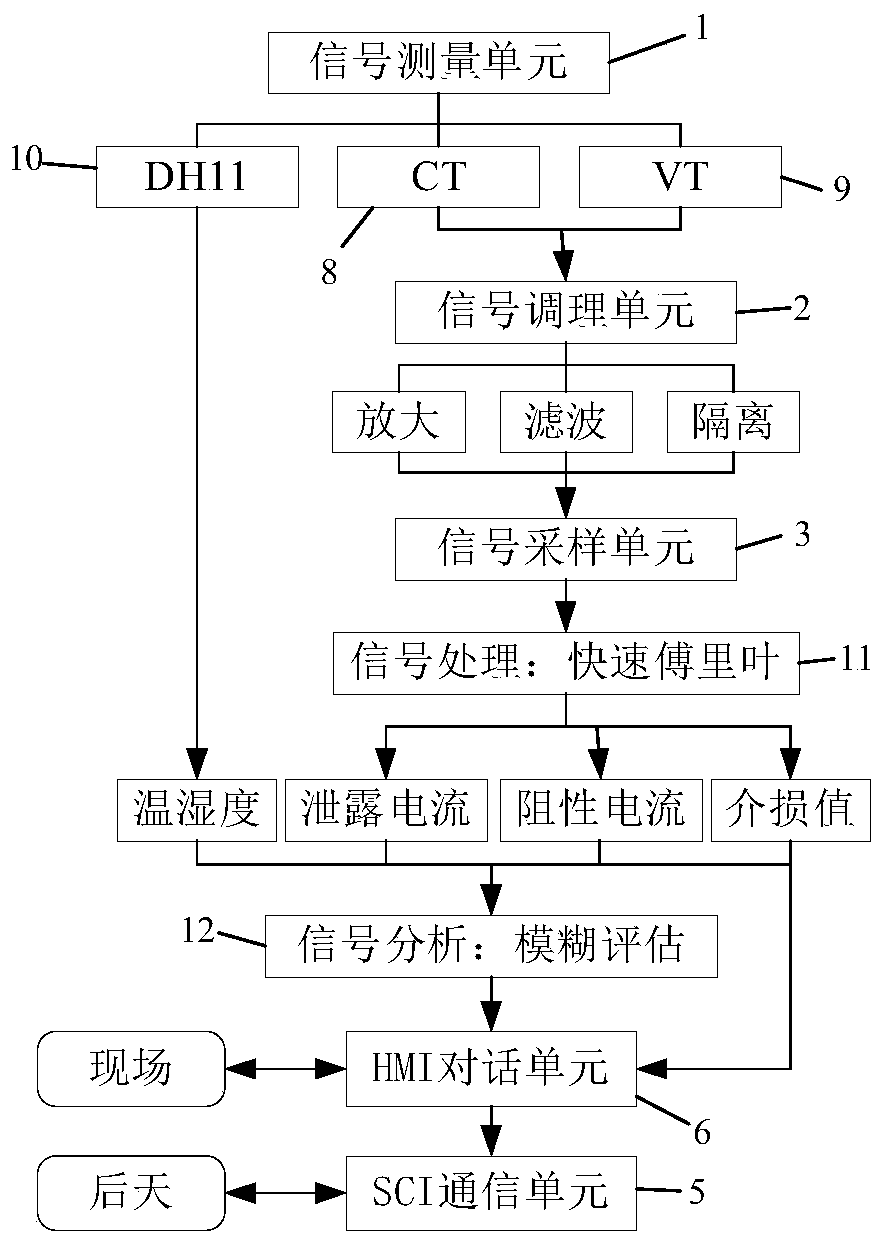

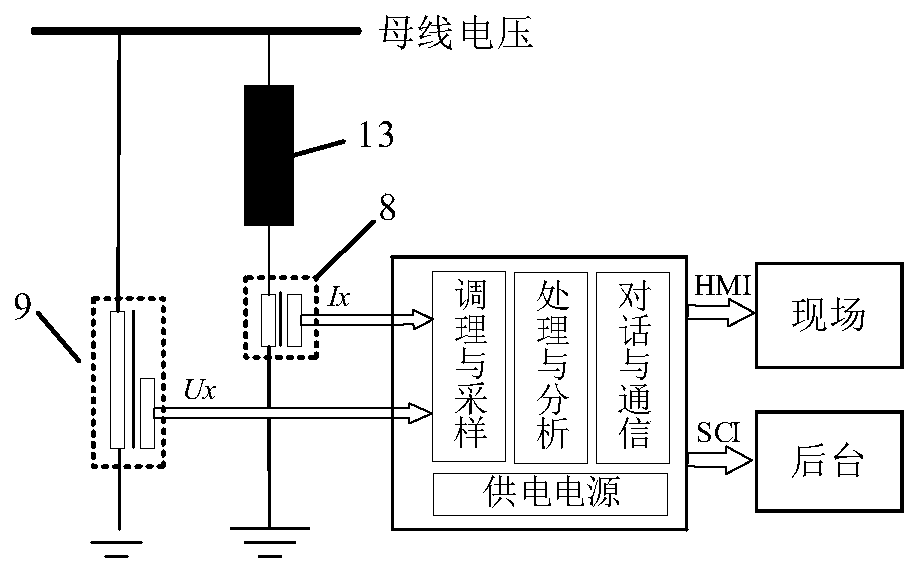

[0050] Such as Figure 1~3 As shown, an on-site evaluation device for the insulation performance of substation capacitive equipment includes a signal measurement unit 1, a signal conditioning unit 2, a signal sampling unit 3, an embedded processor 4, a signal communication unit 5, an HMI human-computer interaction unit 6 and Power module 7;

[0051] The signal measuring unit 1 includes a current transformer 8, a voltage transformer 9 and a temperature and humidity sensor 10;

[0052] Described embedded processor 4 comprises signal processing unit 11 and signal analysis unit 12;

[0053] The current transformer 8 and the voltage transformer 9 are respectively connected to the input terminals of the signal conditioning unit 2;

[0054] The output end of the signal conditioning unit 2 is connected to the input end of the signal sampling unit 3;

[0055] The output ends of the temperature and humidity sensor 10 and the signal sampling unit 3 are respectively connected to the in...

Embodiment 2

[0070] Such as Figure 1~3 As shown, an on-site evaluation device for the insulation performance of substation capacitive equipment includes a signal measurement unit 1, a signal conditioning unit 2, a signal sampling unit 3, an embedded processor 4, a signal communication unit 5, an HMI human-computer interaction unit 6 and Power module 7;

[0071] The signal measuring unit 1 includes a current transformer 8, a voltage transformer 9 and a temperature and humidity sensor 10;

[0072] Described embedded processor 4 comprises signal processing unit 11 and signal analysis unit 12;

[0073] The current transformer 8 and the voltage transformer 9 are respectively connected to the input terminals of the signal conditioning unit 2;

[0074] The output end of the signal conditioning unit 2 is connected to the input end of the signal sampling unit 3;

[0075] The output ends of the temperature and humidity sensor 10 and the signal sampling unit 3 are respectively connected to the in...

Embodiment 3

[0097] Such as Figure 1~3 As shown, an on-site evaluation device for the insulation performance of substation capacitive equipment includes a signal measurement unit 1, a signal conditioning unit 2, a signal sampling unit 3, an embedded processor 4, a signal communication unit 5, an HMI human-computer interaction unit 6 and Power module 7;

[0098] The signal measuring unit 1 includes a current transformer 8, a voltage transformer 9 and a temperature and humidity sensor 10;

[0099] Described embedded processor 4 comprises signal processing unit 11 and signal analysis unit 12;

[0100] The current transformer 8 and the voltage transformer 9 are respectively connected to the input end of the signal conditioning unit 2 through an analog electrical signal path;

[0101] The output end of the signal conditioning unit 2 is connected to the input end (ADC interface) of the signal sampling unit 3;

[0102] The output ends of the temperature and humidity sensor 10 and the signal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com