Oil pipe design method and device of well completion pipe string and storage medium

A technology of completion string and design method, which is applied in the field of oil and gas well engineering, can solve the problems of reduced pressure bearing capacity of tubing, deviation of triaxial safety factor, and increase of production operation cost of completion string, so as to reduce production operation cost, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

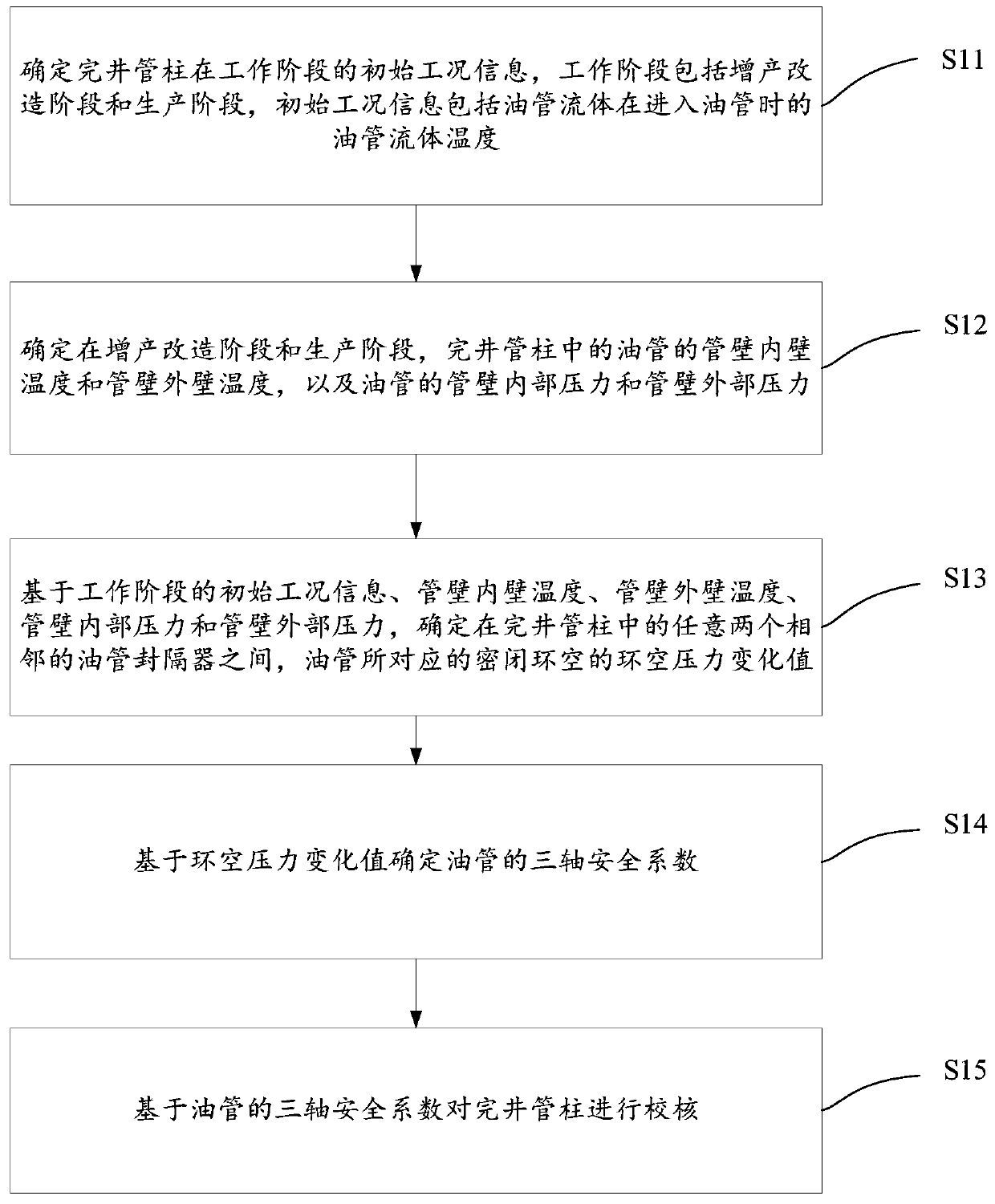

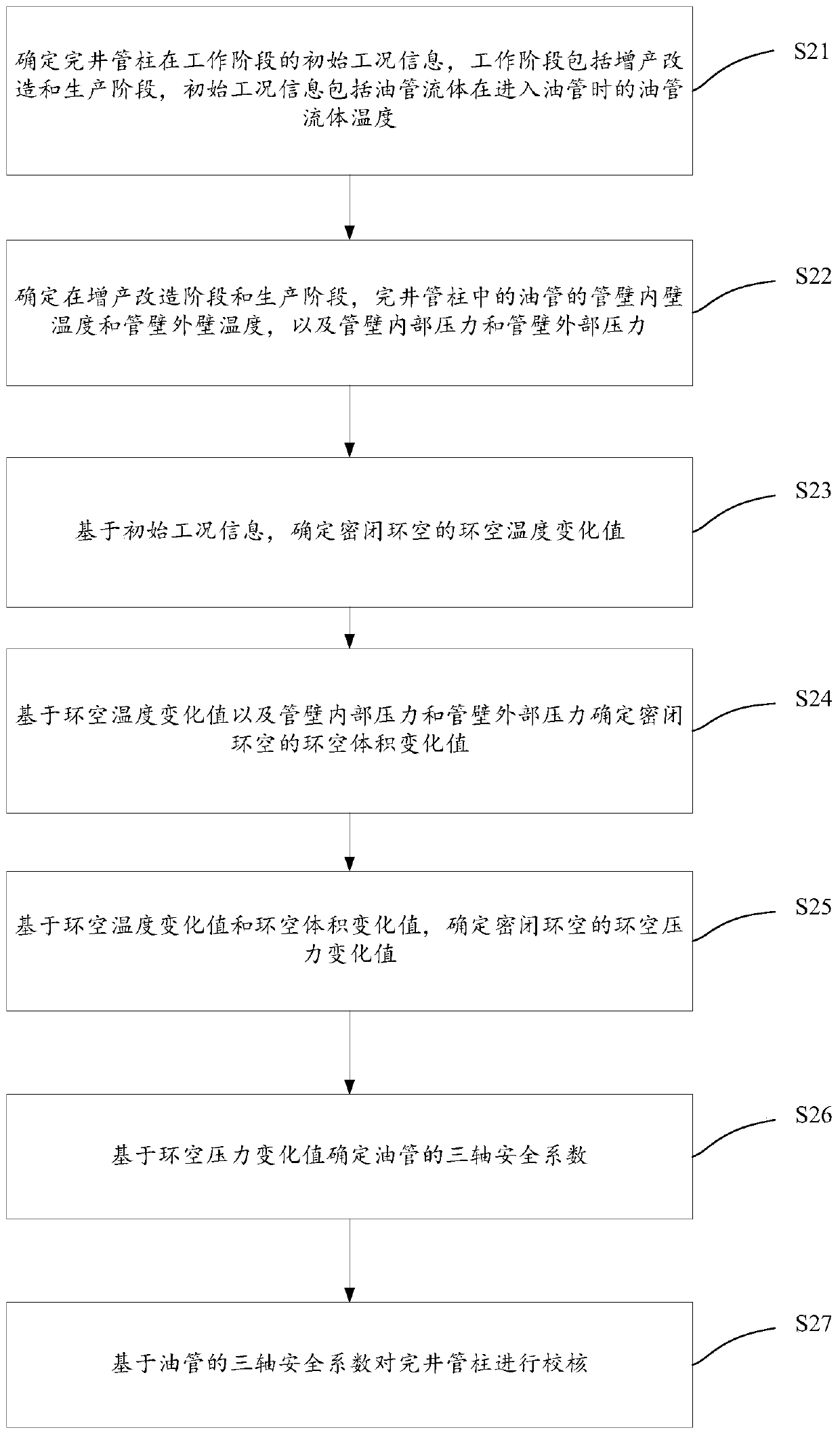

[0058] figure 1 It is a flow chart of a tubing design method for a well completion string provided by an embodiment of the present disclosure. like figure 1 As shown, the tubing design methods for completion strings include:

[0059] Step S11, determining the initial working condition information of the completion string in the working stage, the working stage includes the stimulation stage and the production stage, and the initial working condition information includes the tubing fluid temperature when the tubing fluid enters the tubing;

[0060] Step S12, determining the inner wall temperature and the outer wall temperature of the tubing in the completion string, as well as the inner pressure and outer pressure of the tubing wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com