Simulated 3D ceramic polishing process

A ceramic polishing, 3D technology, applied in design optimization/simulation, special data processing applications, digital data authentication, etc., can solve problems such as unfavorable mastery, cumbersome operation, and many polishing processes, so as to reduce the risk of theft and improve operation. Efficiency and the effect of improving verification strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

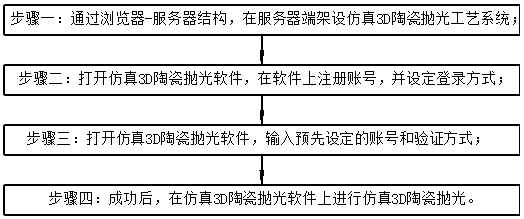

[0025] see figure 1 , the present invention provides a technical solution: a simulated 3D ceramic polishing process, comprising the following steps:

[0026] Step 1: Set up a simulated 3D ceramic polishing process system on the server side through the browser-server structure;

[0027] Step 2: Open the simulated 3D ceramic polishing software, register an account on the software, and set the login method; and bind the registered account with a mobile phone or email, so that the account can be retrieved when the account is forgotten;

[0028] Step 3: Open the simulated 3D ceramic polishing software, and enter the pre-set account number and verification method;

[0029] Step 4: After success, perform simulated 3D ceramic polishing on the simulated 3D ceramic polishing software.

[0030] In this embodiment, preferably, it also includes an audit module for auditing registered accounts. Only authorized accounts that have passed the audit can use the simulated 3D ceramic polishing ...

Embodiment 2

[0046] see figure 1 , the present invention provides a technical solution: a simulated 3D ceramic polishing process, comprising the following steps:

[0047] Step 1: Set up a simulated 3D ceramic polishing process system on the server side through the browser-server structure;

[0048] Step 2: Open the simulated 3D ceramic polishing software, register an account on the software, and set the login method; and bind the registered account with a mobile phone or email, so that the account can be retrieved when the account is forgotten;

[0049] Step 3: Open the simulated 3D ceramic polishing software, and enter the pre-set account number and verification method;

[0050] Step 4: After success, perform simulated 3D ceramic polishing on the simulated 3D ceramic polishing software.

[0051] In this embodiment, preferably, it also includes an audit module for auditing registered accounts. Only authorized accounts that have passed the audit can use the simulated 3D ceramic polishing ...

Embodiment 3

[0067] see figure 1 , the present invention provides a technical solution: a simulated 3D ceramic polishing process, comprising the following steps:

[0068] Step 1: Set up a simulated 3D ceramic polishing process system on the server side through the browser-server structure;

[0069] Step 2: Open the simulated 3D ceramic polishing software, register an account on the software, and set the login method; and bind the registered account with a mobile phone or email, so that the account can be retrieved when the account is forgotten;

[0070] Step 3: Open the simulated 3D ceramic polishing software, and enter the pre-set account number and verification method;

[0071] Step 4: After success, perform simulated 3D ceramic polishing on the simulated 3D ceramic polishing software.

[0072] In this embodiment, preferably, it also includes an audit module for auditing registered accounts. Only authorized accounts that have passed the audit can use the simulated 3D ceramic polishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com