Aviation direct-current distribution relay

A technology of DC power distribution and relays, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve problems such as instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

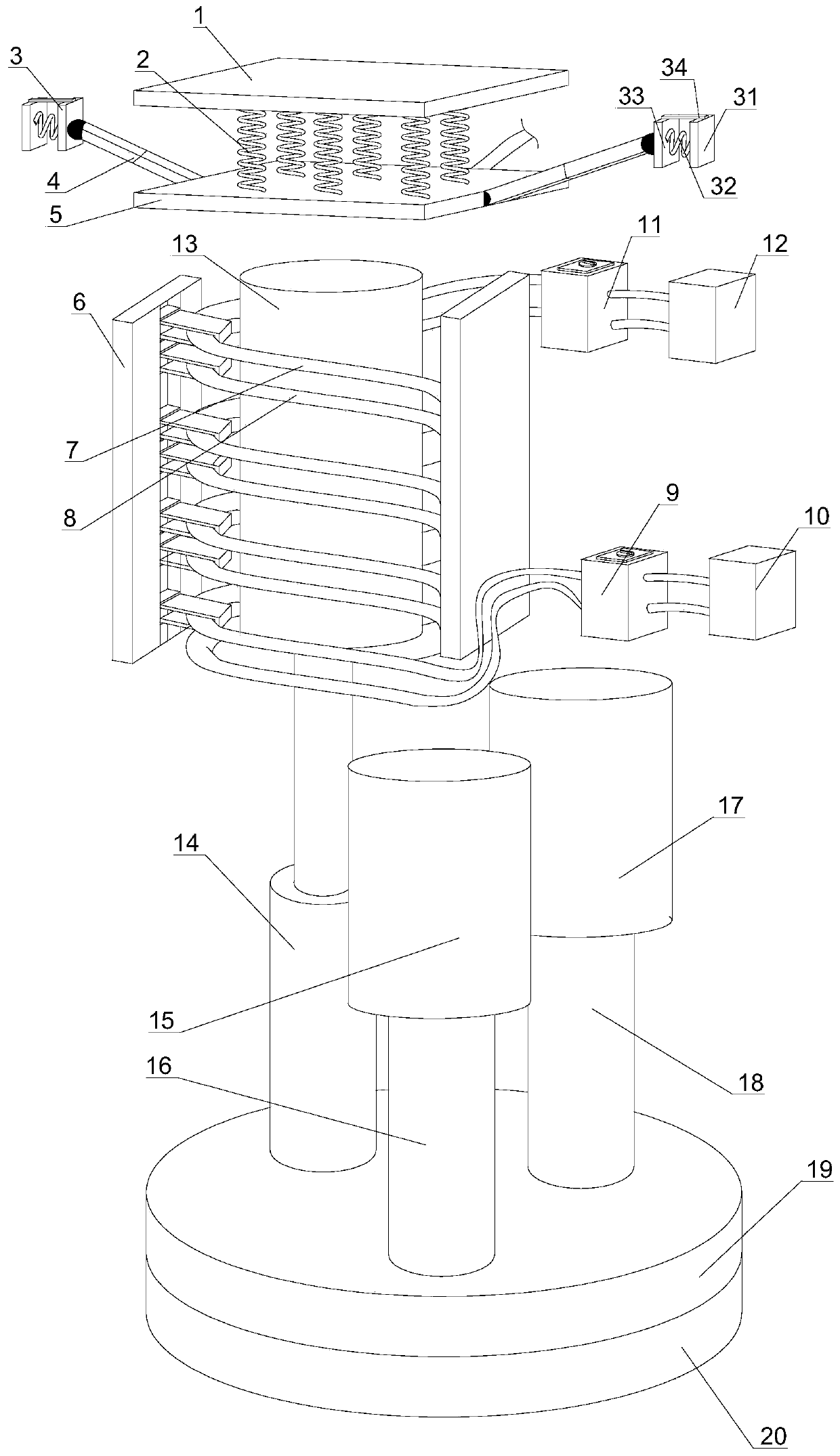

[0033] Such as Figure 1~3As shown, the aeronautical DC power distribution relay described in this implementation includes a top case 1, an attraction plate 5 is provided under the top case 1, and an elastic recovery member is provided between the attraction plate 5 and the top case 1, and the elastic recovery One end of the part is fixedly connected with the suction plate 5, and the other end of the elastic recovery part is fixedly connected with the top shell 1. The side of the suction plate 5 is provided with an extended fixed rod 4, and one end of the extended fixed rod 4 is hinged with the suction plate 5, extending The other end of the fixed rod 4 is provided with a telescopic buffer assembly 3, and the extended fixed rod 4 is hinged with the telescopic buffer assembly 3. A wire holder 6 is provided below the suction plate 5, and a group of first wire holders are coiled and fixed on the wire holder 6. One electric wire 7 and several groups of secondary electric wires, th...

Embodiment 2

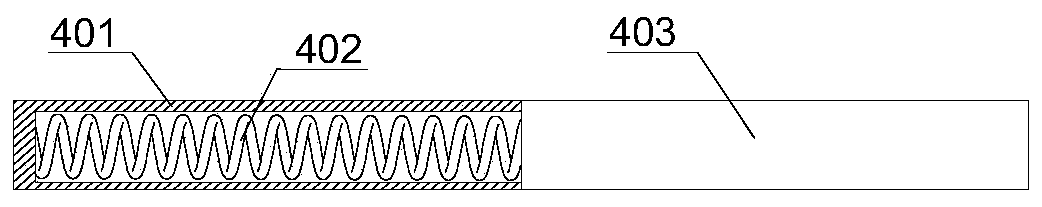

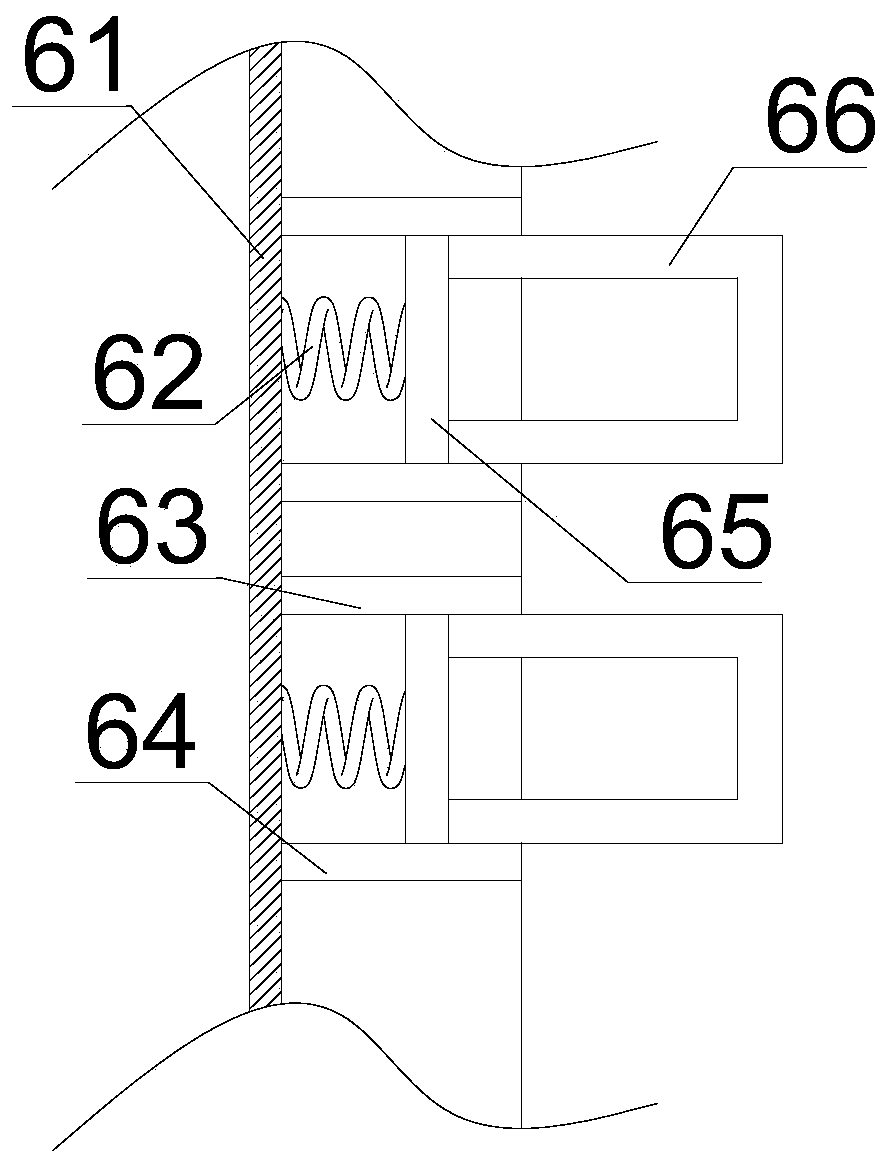

[0040] Such as Figure 1~4 As shown, on the basis of Embodiment 1, the secondary energizing wires are a set of second energizing wires 8, the lower tightening assembly 9 includes a tightening shell 97, and the upper surface of the tightening shell 97 is provided with Press the lock button 91, the press lock button 91 penetrates the upper surface of the tightening shell 97 and extends to the inside of the tightening shell 97, the lower surface of the press lock button 91 is provided with a lower pressing rod 94, and the lower pressing rod 94 is connected with the pressing lock The button 91 is fixed, and a reset plate 93 and two lower press plates 96 are sequentially arranged on the lower pressure rod 94 from top to bottom. The reset plate 93 extends away from the center of the push knob, and the lower press plate 96 extends toward the center of the push knob. , and the two lower pressure plates 96 are parallel to each other, and a reset extension spring 92 is also provided bet...

Embodiment 3

[0042] Such as Figure 1-5 As shown, on the basis of any one of embodiments 1 to 2, the push lock button 91 includes a knob housing 911, the upper surface of the knob housing 911 is provided with a rotating disk 919, and the upper surface of the rotating disk 919 is provided with a handle 920 , the handle 920 is fixed to the rotating disk 919, the lower surface of the rotating disk 919 is provided with a rotating shaft 921, the rotating shaft 921 runs through the rotating casing and extends to the inside of the rotating casing, one end of the rotating shaft 921 is fixed to the lower surface of the rotating disk 919, and rotates The other end of the shaft 921 is provided with a first horizontal gear 915, the side of the first horizontal gear is provided with a second horizontal gear 918, the first horizontal gear 915 and the second horizontal gear 918 mesh, the first horizontal gear 915 The bottom is provided with a first vertical gear 914, the first horizontal gear 915 meshes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com