GIL equipment standard unit based on novel internal structure and implementation method

A technology of internal structure and standard unit, applied in the field of electric power, can solve problems such as the impact of sliding three-pillar insulators on electrical performance and grounding reliability, adverse social impacts, and economic losses, so as to improve equipment operation reliability, avoid discharge failures, reduce The effect of back-and-forth wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

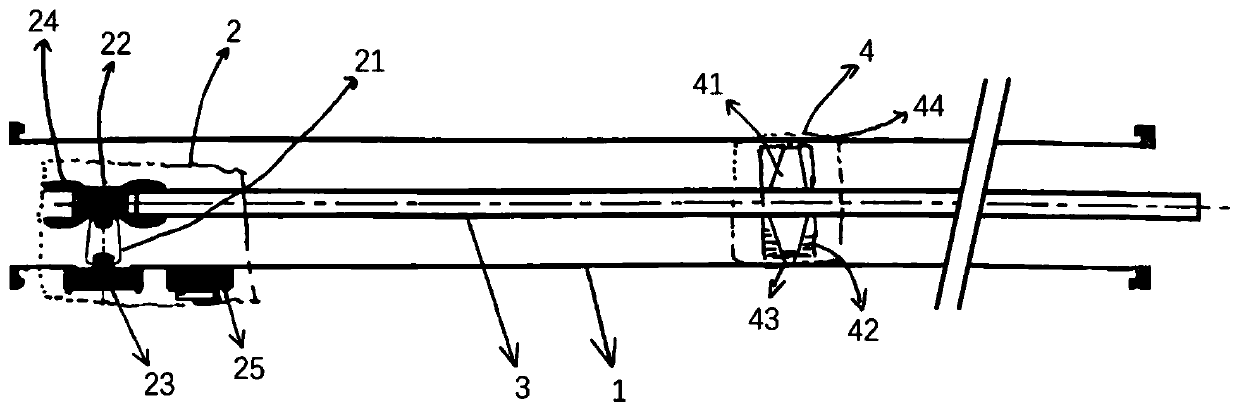

[0026] Such as figure 1 As shown, a GIL equipment standard unit based on a new internal structure in this embodiment mainly includes a GIL pipe 1 , a single-post insulator assembly 2 , a long conductive rod 3 and a sliding three-post insulator assembly 4 .

[0027] The length of the GIL pipeline 1 is set to 12-18m. The left end of the long conductive rod 3 is supported by a single-pillar insulator assembly 2, and the middle part of the long conductive rod 3 is supported by one or two sliding three-pillar insulator assemblies.

[0028] The single post insulator assembly 2 includes a single post insulator 21 , a short conductive rod 22 and a metal sealing cover plate 23 . The two sides of the short conductive rod 22 are provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com