Machining method for special-shaped guide groove

A processing method and technology of guide grooves, which are applied in the field of special-shaped parts processing, can solve the problems of high labor intensity, unguaranteed size, and low efficiency of special-shaped guide grooves, so as to reduce labor intensity, reduce labor intensity of workers, save drilling and repair The effect of the shaping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but this embodiment should not be construed as limiting the present invention.

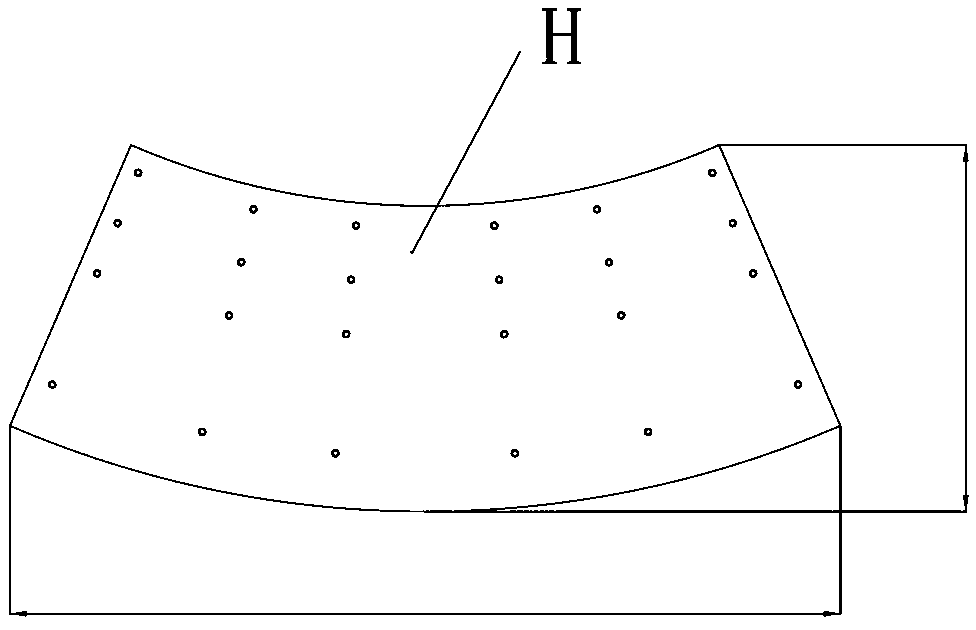

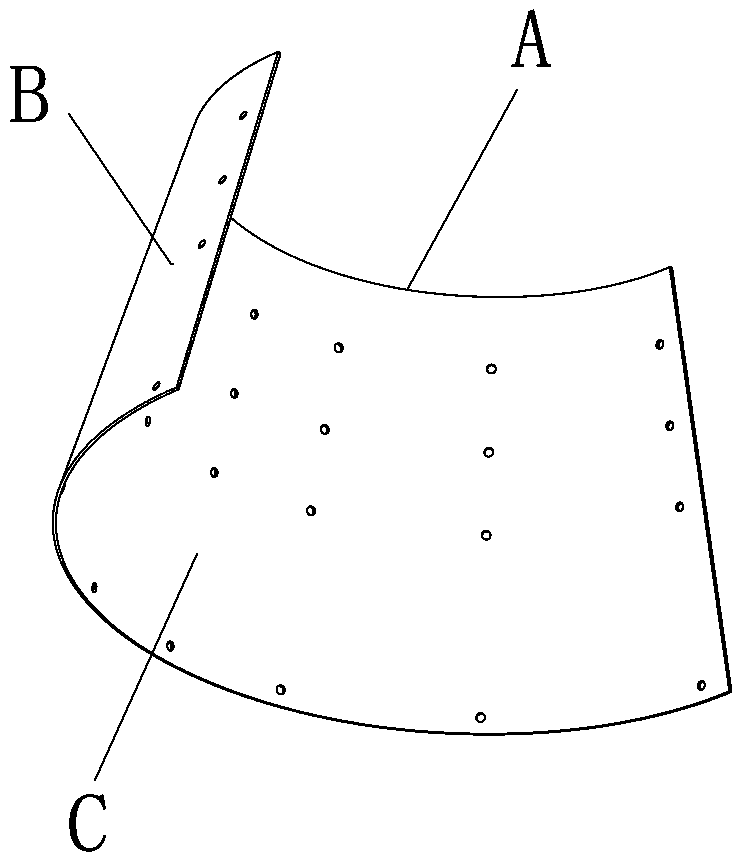

[0034] combine Figure 3 to Figure 8 , and combined with Figure 1 to Figure 2 The special-shaped guide groove shown is further described as follows for the special fixture used for processing: the special fixture includes a base plate 1, and two parallel guide baffles 2 are fixed on the base plate 1, and the guide baffles are two back-to-back arrangements. The L-shaped baffle, between the two guide baffles, a pressure-bearing bracket is fixed on one side in the length direction, a pressure-applying bracket that can slide and move along the guide baffle is installed in the middle, and a pressure bracket is fixed on the other side along the width direction of the guide baffle. screw mounting plate 3,

[0035] The height of the pressure-applying brack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com