A kind of mechanical processing equipment with reversible clamping mechanism

A technology of mechanical processing and clamping mechanism, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve the problems that it is difficult to meet the processing and use requirements of complex workpieces, the adjustable range is small, and metal debris is easy to scatter everywhere, reaching the realization level The effect of rotating the adjustment operation, increasing the adjustment range, and reducing the separation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

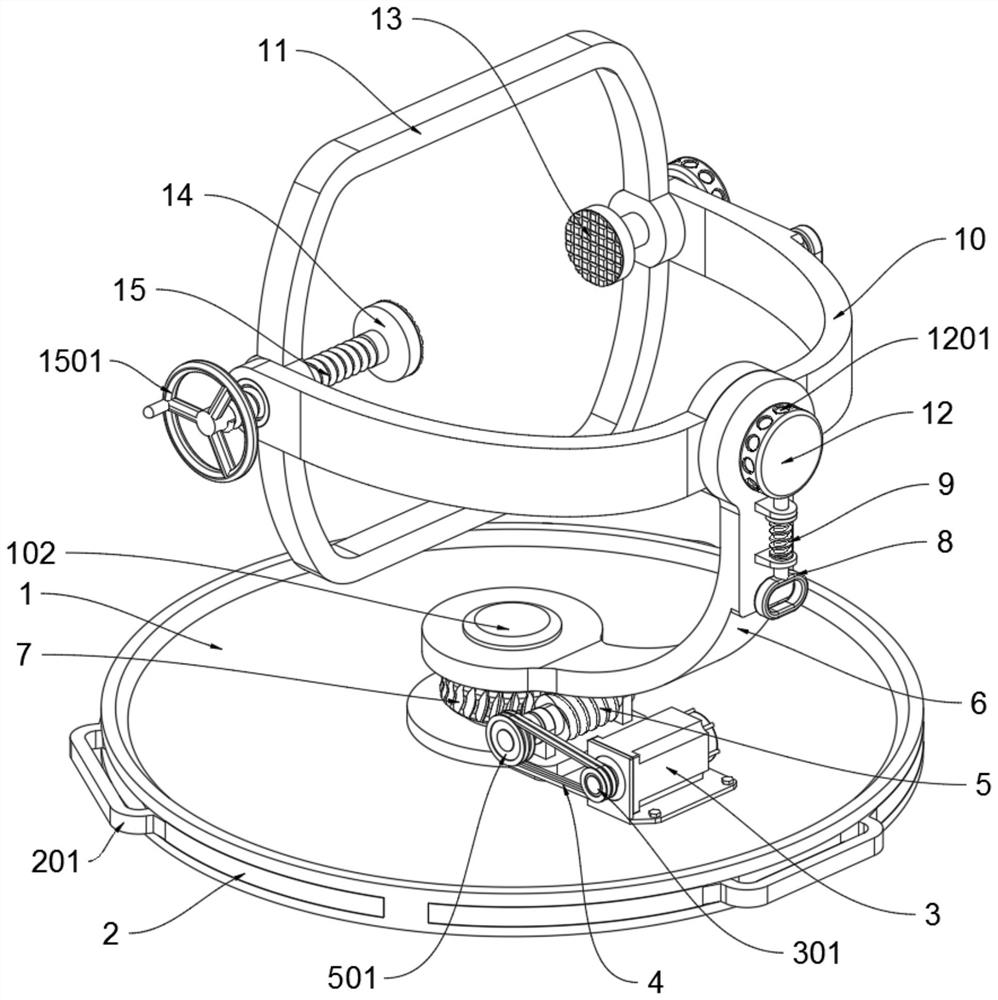

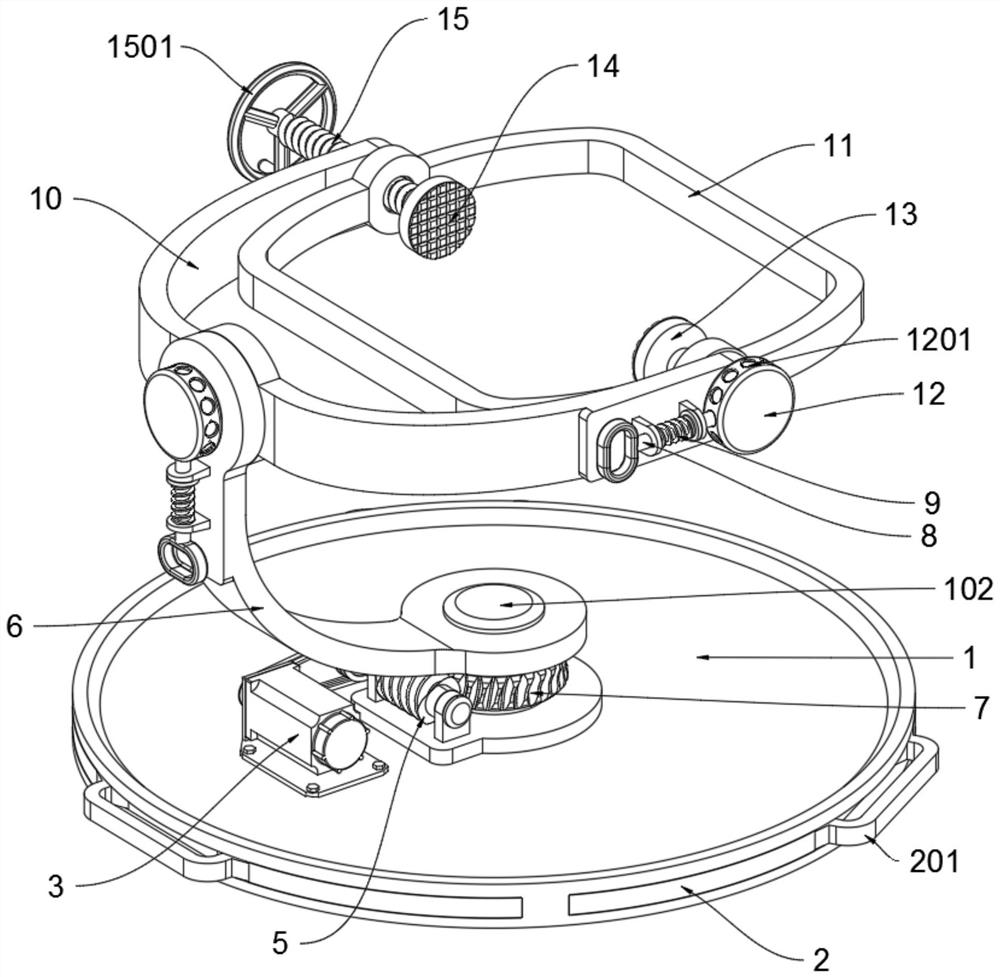

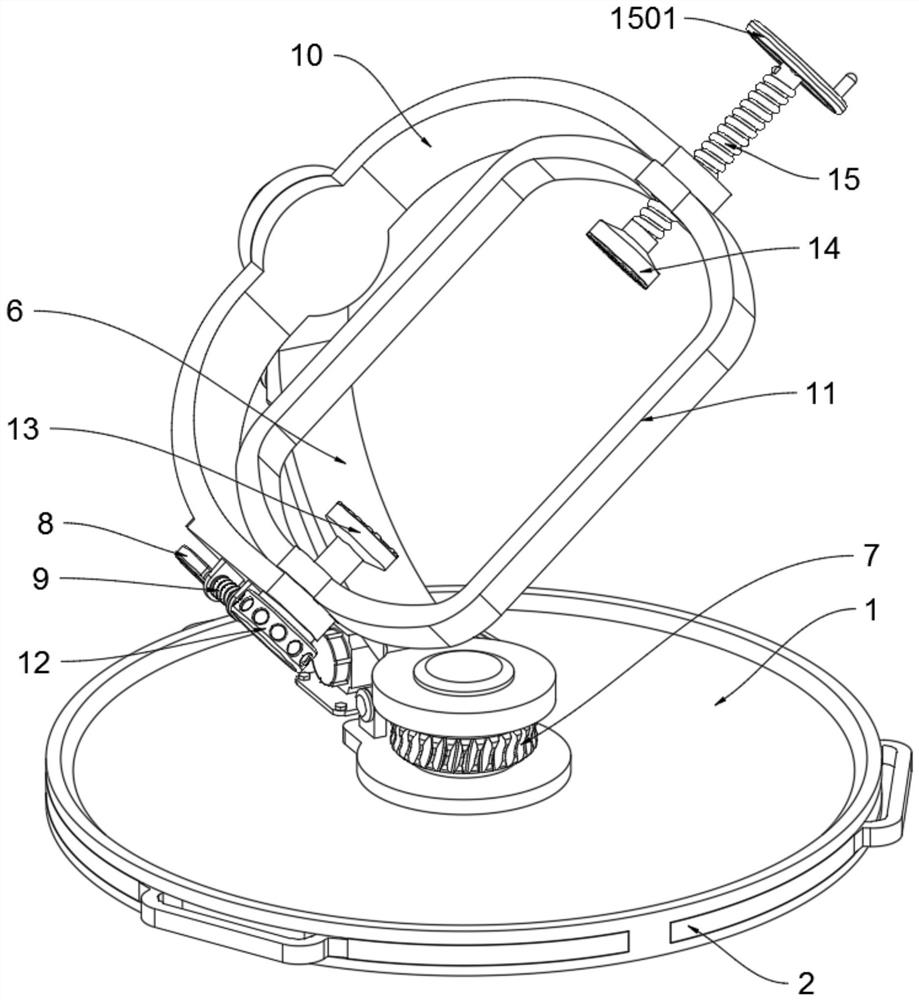

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides a kind of mechanical processing equipment with a reversible clamping mechanism, which includes a base 1, a drive motor 3, a support 6, a limit pin 8, a rotating block 12, a fixed clamping block 13 and a screw 15; the base 1 is a circular structure There is a rotating shaft 102 at the center of the top of the base 1; there are three transfer slots 101 inside the base 1 in a circular shape. Inside, the outer end of the magnetic board 2 is provided with a handle 201, which can absorb the metal debris falling to the top of the base 1 through the suction force generated by the magnetic board 2 when the workpiece on the top of the base 1 is being processed, so that personnel can regularly clean the base. 1 The metal debris adsorbed on the top is collected and processed to avoid metal debris scattered everywhere and affect the cleanliness of the surrounding processing environment; the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com