Raw material screening equipment used for fire hose glue layer production and application method of raw material screening equipment

A technology for fire hoses and screening equipment, which is applied to chemical instruments and methods, sieves, and solid separation. It can solve the problems of high labor intensity and low work efficiency, and achieve improved work efficiency, fast separation speed, and reduced work pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

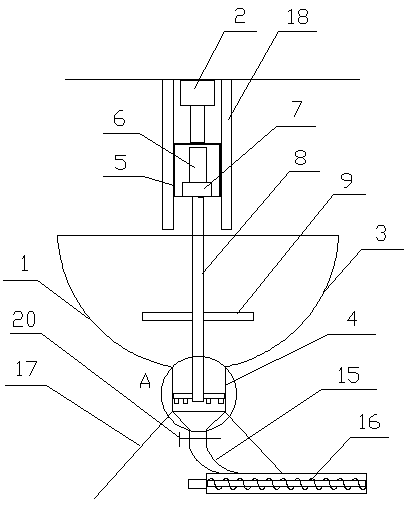

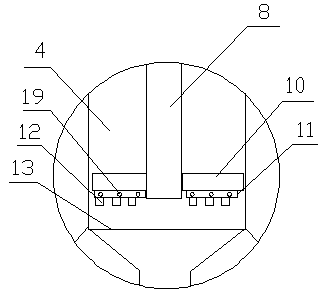

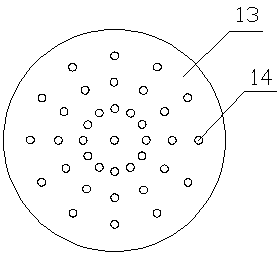

[0029] As shown in the figure, a kind of raw material screening equipment used for the production of fire hose rubber layer according to the present invention includes a screening box 1 and a cylinder 2. The screening box 1 is vertically placed on the ground, and the screening box 1 Comprising a break-up area 3 and a separation area 4 that are connected to each other, the break...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com