Battery fixing device and terminal equipment

A battery fixing and battery technology, applied in the electronic field, can solve the problems of damaged battery, battery deformation, high cost, etc., and achieve the effect of reducing cost, reducing deformation, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

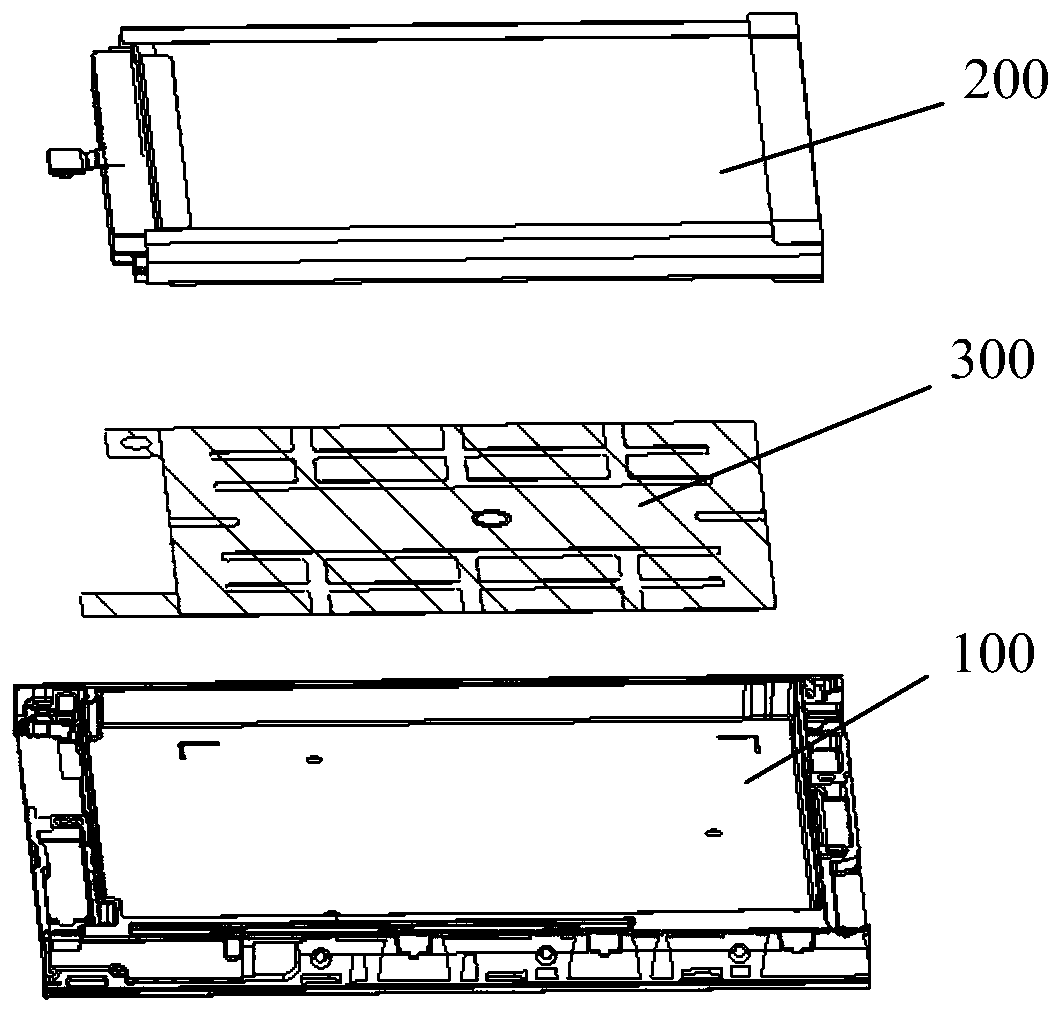

[0048]When the user disassembles the battery 200 in the above-mentioned battery fixing device, the organic alcohol is first dropped into the edge of the battery compartment 100, the alcohol flows into the bottom of the battery compartment 100, and then a swelling reaction occurs along the liquid guide groove and the adhesive structure 300, so that the The adhesive structure 300 fails, and the user can suck the battery 200 out of the battery compartment 100 through the suction cup.

[0049] In the present invention, organic substances include alcohol, methanol and the like.

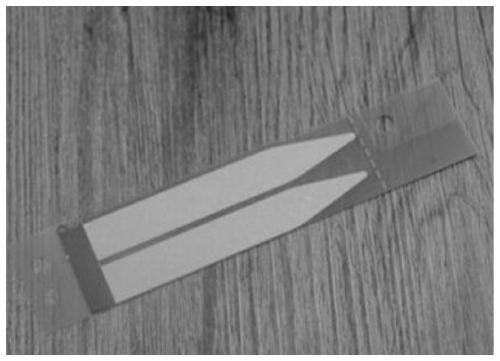

[0050] Figure 5 Exemplarily shows a schematic diagram of a bonded structure, such as Figure 5 As shown, when the adhesive structure 300 is not installed on the battery 200, the adhesive structure 300 is also adhered with a release paper 500 similar in structure, wherein, Figure 5 The shading of the oblique line is the release paper 500 for protecting the adhesive structure 300. The release paper 500 c...

example 2

[0053] Image 6 Exemplary schematic diagram showing an unmounted bonded structure, such as Image 6 As shown, it includes: a release paper 601 , a positioning hole 602 of the release paper 601 , an adhesive structure 603 , a liquid guide groove 604 of the adhesive structure 603 , and a positioning hole 605 of the adhesive structure 603 .

[0054] When the adhesive structure 603 is not adhesively connected to the battery, the release paper 601 can be connected to the adhesive structure 603 through the positioning hole 602 to protect the adhesive structure 603 .

[0055] When bonding the adhesive structure 603 to the battery, pass the release paper 601 Image 6 The position protruding from the upper right corner of the release paper 601 shown is torn off, so that the release paper 601 is separated from the adhesive structure, and then the adhesive structure 603 is adhered to the battery according to the positioning hole 605 .

[0056] It should be noted that, if Figure 5 wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com