Grinding machine

A grinding machine, grinding technology, applied in the direction of cocoa, grain processing, food science, etc., can solve the problems of difficult cleaning, difficult handling and use, heavy weight, etc., and achieve the effect of easy storage, convenient operation and use, and easy molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

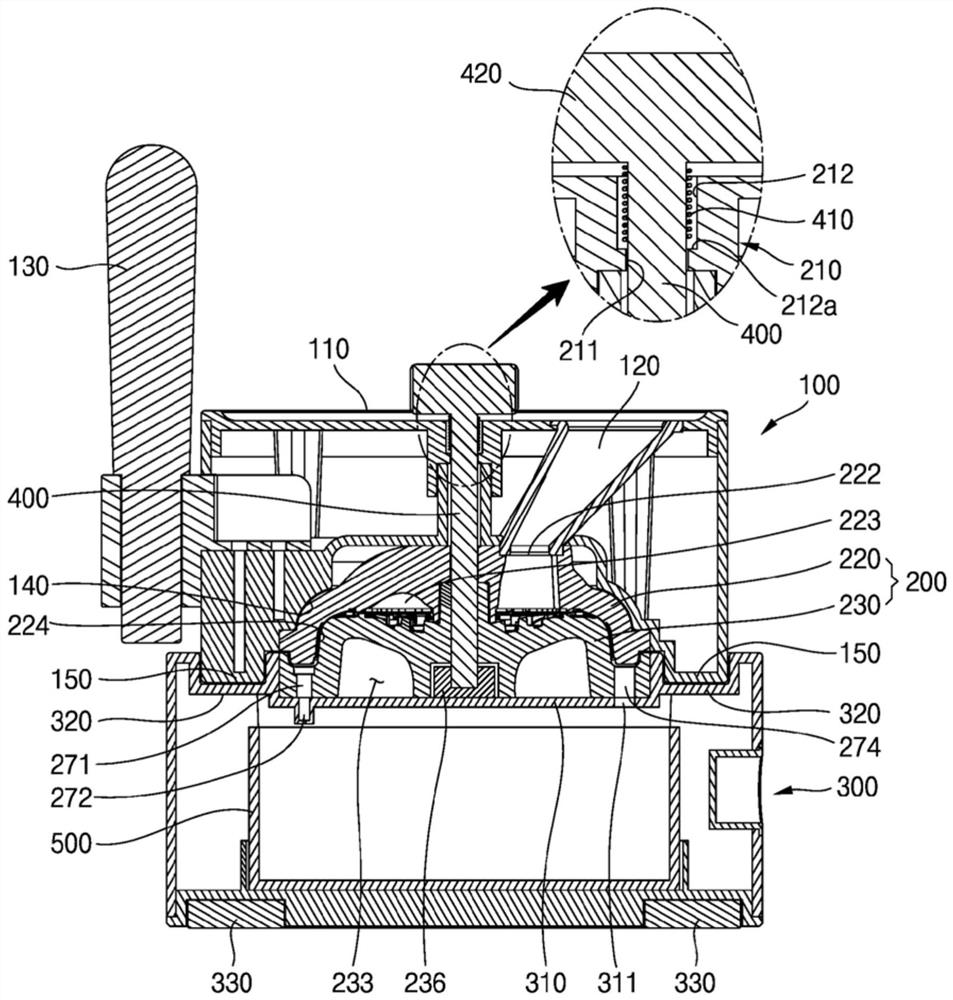

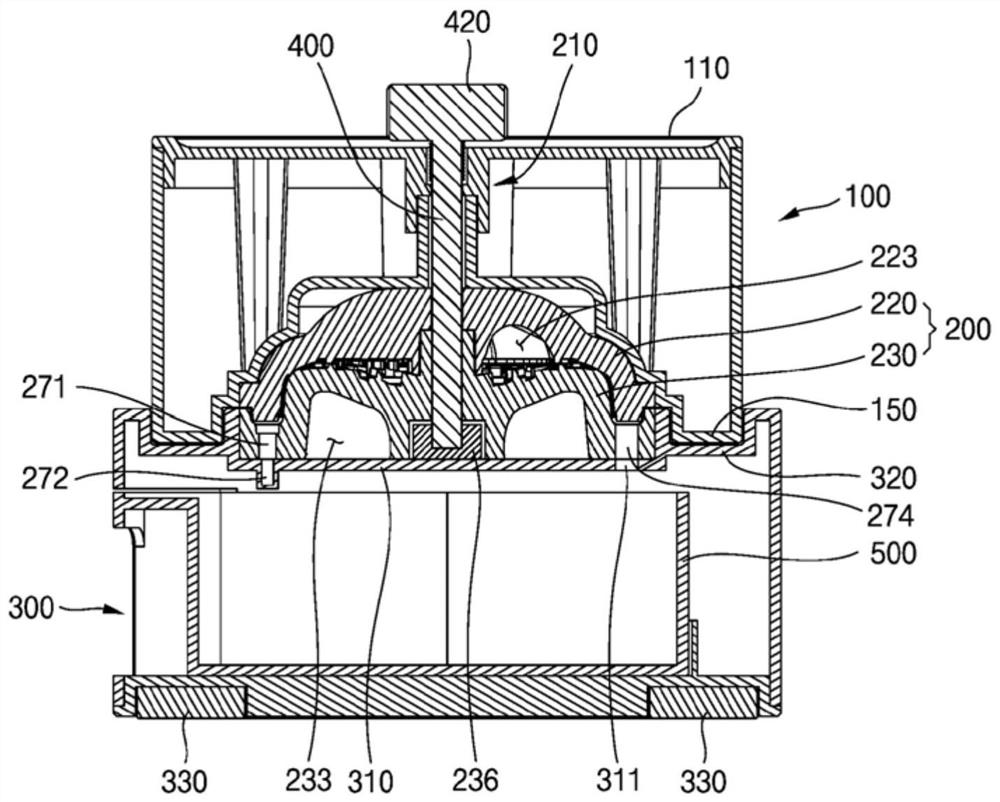

[0027] Hereinafter, a grinding mill according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

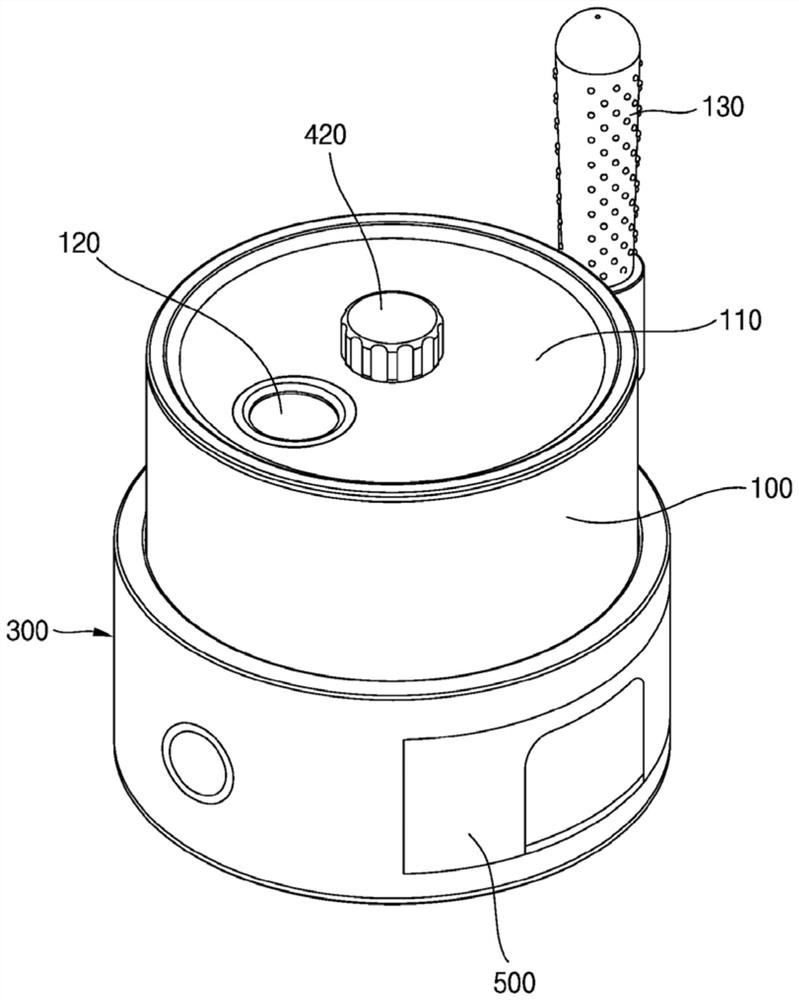

[0028] refer to Figure 1 to Figure 3 , the grinding mill of the present invention includes an upper body 100 , a grinding assembly 200 and a lower body 300 .

[0029] The upper surface 110 of the upper body 100 is provided with an opening hopper 120 . The feeding port 120 serves as a path for feeding objects to be ground. A handle 130 for rotating the upper body 100 is provided on one side of the upper body 100 .

[0030] An installation groove portion 140 is formed in the upper body 100 , and an upper grinding portion 220 constituting an upper portion of the grinding assembly 200 is provided inside the installation groove portion 140 . The upper grinding part 220 is configured and fixed inside the setting groove part 140 . The upper surface of the upper grinding part 220 is supported by providing the groove par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com